- Material:100% virgin tungsten carbide

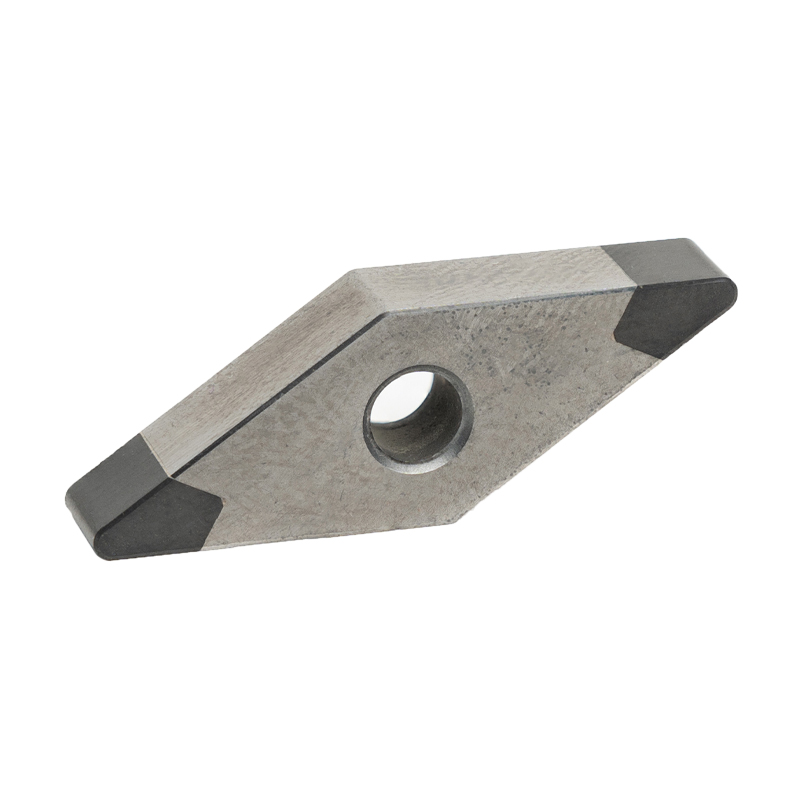

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Opis

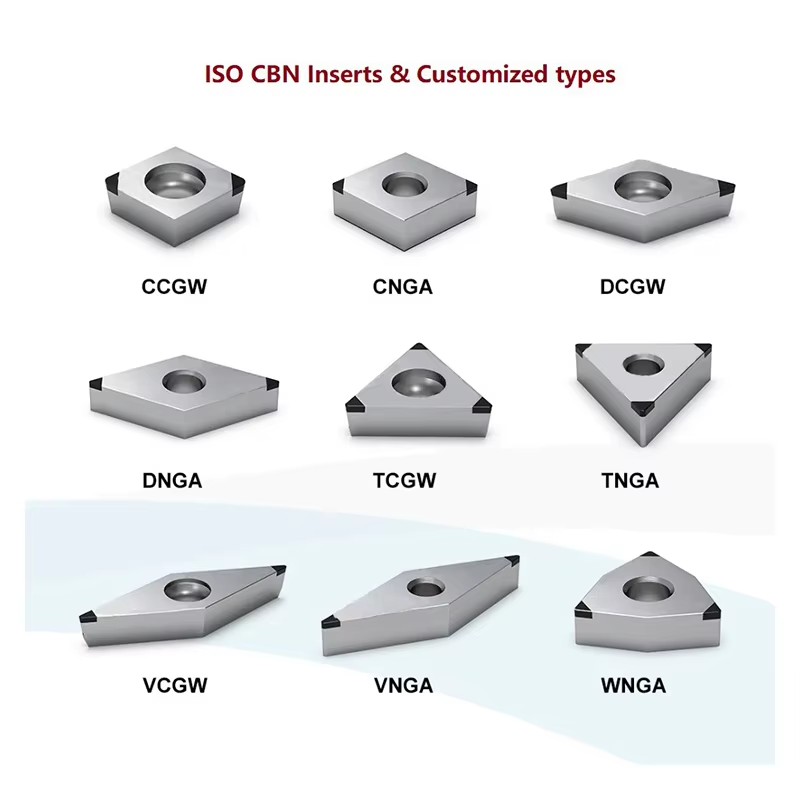

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

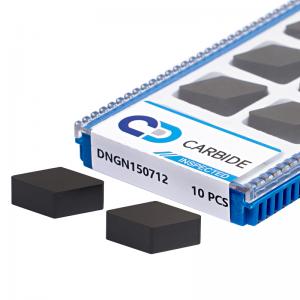

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

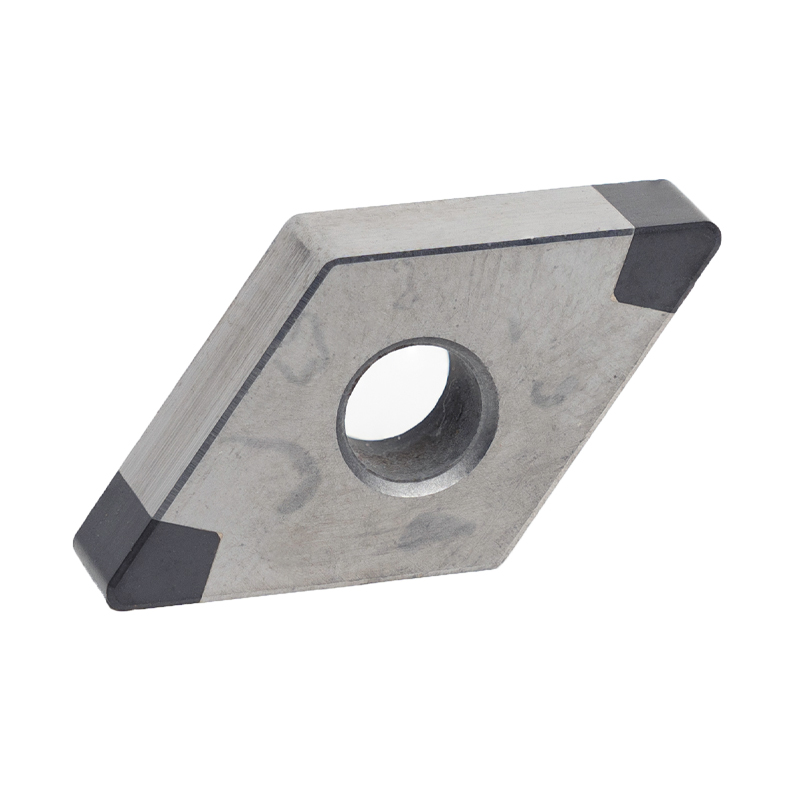

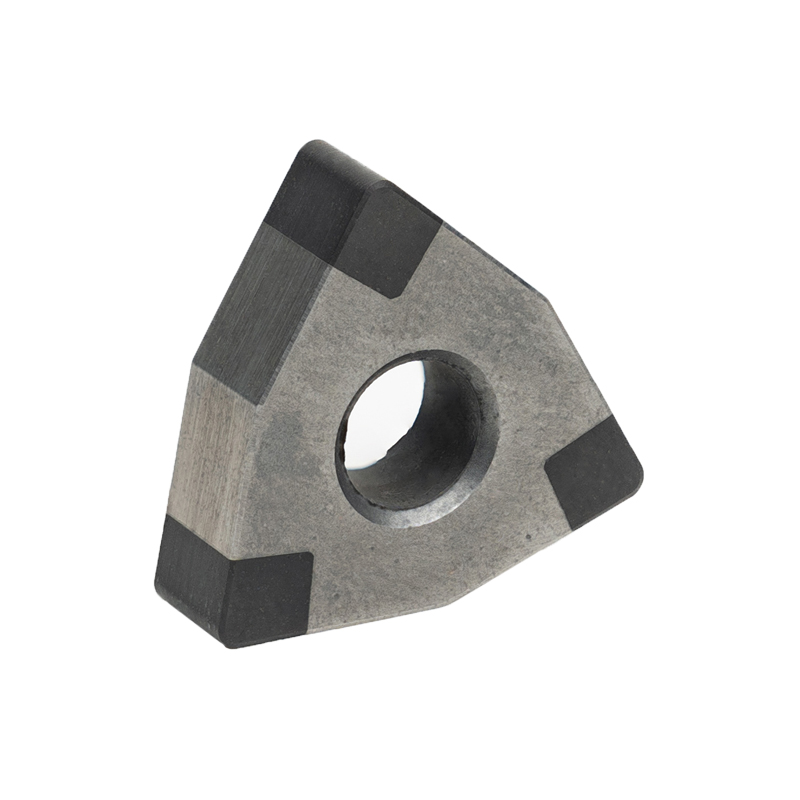

Welded cubic boron nitride blade

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

FAQ

1) Kada mogu dobiti cijenu?

Obično citiramo u roku od 24 sata nakon što dobijemo vaš upit. Ako ste vrlo hitni da dobijete cijenu, pozovite nas ili nam recite u svojoj e-pošti kako bismo razmotrili prioritet vašeg upita.

2) Kako mogu dobiti uzorak da provjerim vaš kvalitet?

Nakon potvrde cijene, možete zatražiti uzorke kako biste provjerili naš kvalitet. Ako vam je potreban samo prazan uzorak da provjerite dizajn i kvalitet papira, mi ćemo vam dati uzorak besplatno, sve dok si priuštite ekspresnu dostavu.

3) Koliko dugo mogu očekivati da dobijem uzorak?

Nakon što platite cijenu uzorka i pošaljete nam potvrđene datoteke, uzorci će biti spremni za isporuku za 3-7 dana. Uzorci će vam biti poslati putem ekspresa i stići za 3-7 radnih dana. Možete koristiti svoj brzi račun ili nam platiti unaprijed ako nemate račun.

4) Koliko dugo se razrađuje cijela procedura?

Nakon što naručite, vrijeme proizvodnje je oko 20-25 dana. Potrebno nam je 7 dana da pripremimo sve stvari, a zatim 15 dana za proizvodnju.

5) Šta je sa transportom i datumom isporuke?

Obično koristimo pošiljku za transport robe. To je oko 7-25 dana. Takođe zavisi od toga u kojoj ste zemlji i luci. Može biti kraće ako trebate da pošaljete robu poput Azije. Ako postoje hitni slučajevi, robu možemo poslati avio ekspresom, sve dok vi priuštite troškove saobraćaja.

6) Da li ste trgovačka kompanija ili proizvođač?

Mi smo profesionalni proizvođač. Ne samo da posjedujemo našu tvornicu alata, već imamo i tvornicu cementnog karbida.

7) Gdje se nalazi vaša fabrika?

Nalazimo se u gradu Zhuzhou, provinciji Hunan., gradu na bazi volfram karbida u Kini

8) Koliko dugo mogu očekivati da dobijem uzorak?

Nakon što platite cijenu uzorka i pošaljete nam potvrđene datoteke, uzorci će biti spremni za isporuku za 3-7 dana. Uzorci će vam biti poslati putem ekspresa i stići za 3-5 radnih dana. Možete koristiti svoj brzi račun ili nam platiti unaprijed ako nemate račun.

9) Šta je sa vašim zalihama?

Imamo velike količine proizvoda na lageru, uobičajene vrste i veličine su na zalihama.

10) Da li je moguća besplatna dostava?

Ne nudimo uslugu besplatne dostave. Možemo imati popust ako kupite veću količinu proizvoda

Slobodno me kontaktirajte:

Aimee

Menadžer prodaje

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Okrug Tianyuan, Grad Zhuzhou.

E-pošta: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688