- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

BESKRIUWING

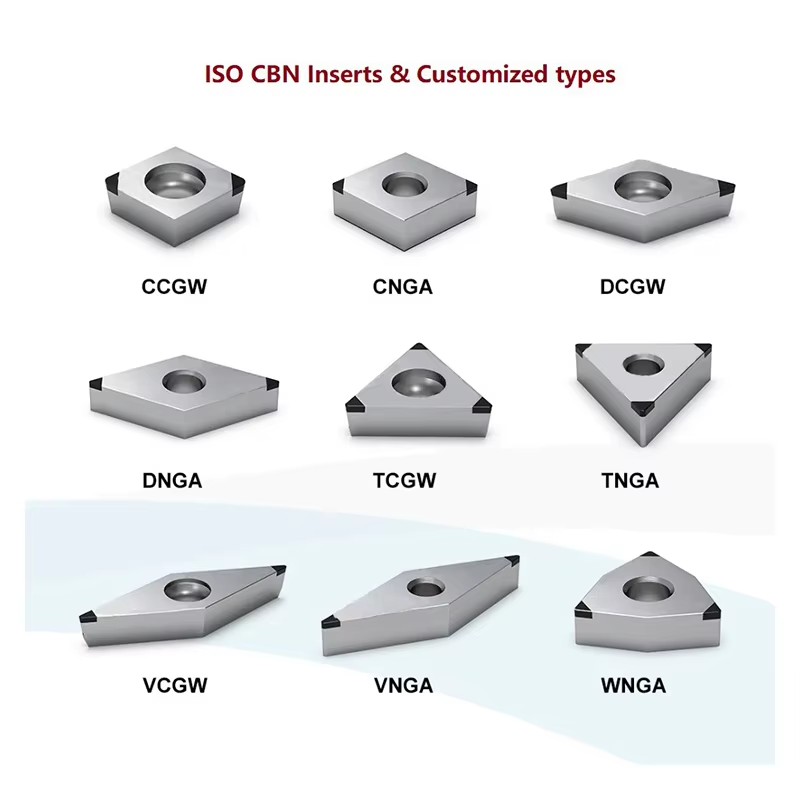

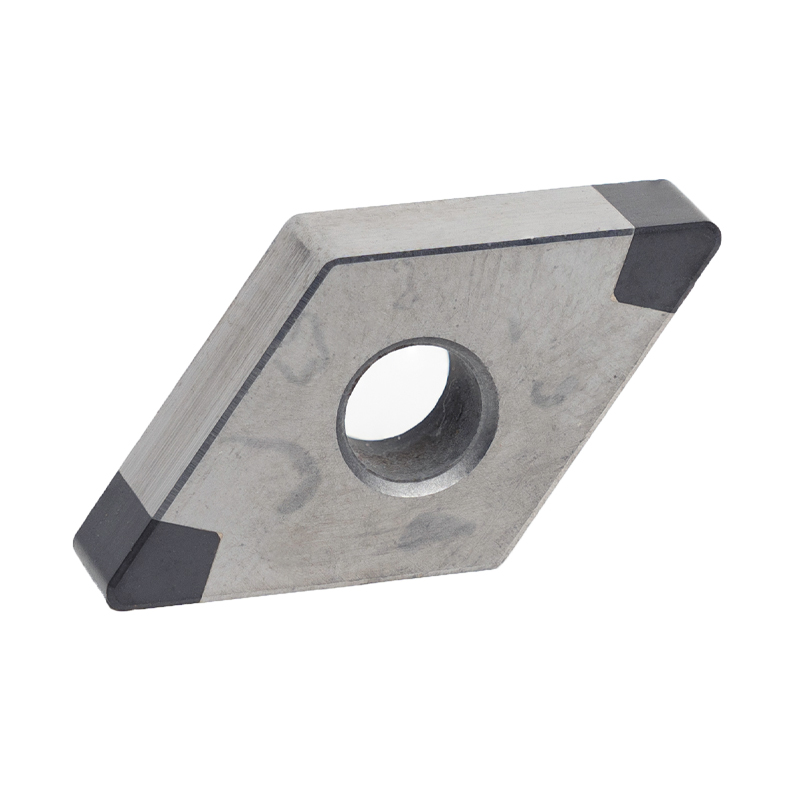

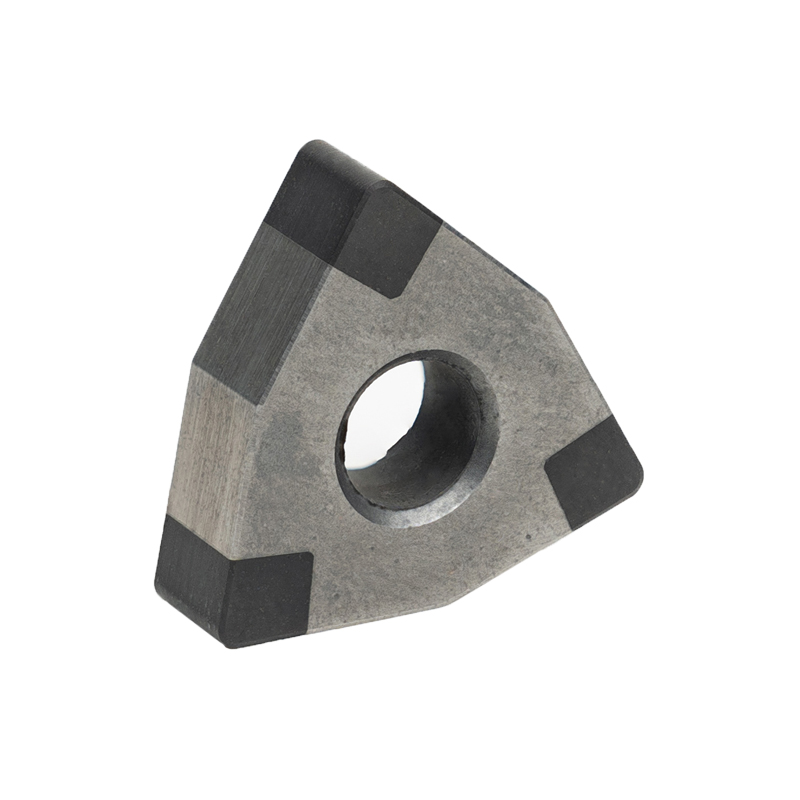

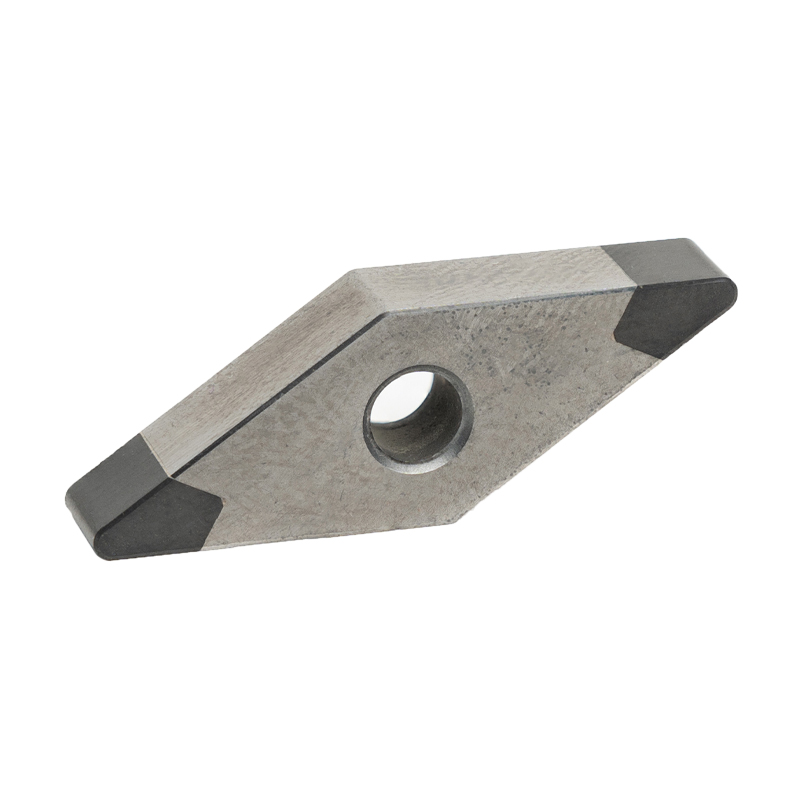

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

Welded cubic boron nitride blade

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

FAQ

1) Wannear kin ik de priis krije?

Wy sitearje normaal binnen 24 oeren nei't wy jo fraach krije. As jo heul driuwend binne om de priis te krijen, belje ús dan asjebleaft of fertel ús yn jo e-post, sadat wy jo ûndersyksprioriteit sille beskôgje.

2) Hoe kin ik in stekproef krije om jo kwaliteit te kontrolearjen?

Nei priisbefêstiging kinne jo samples fereaskje om ús kwaliteit te kontrolearjen. As jo gewoan in lege stekproef nedich binne om it ûntwerp en papierkwaliteit te kontrolearjen, sille wy jo fergees sample leverje, salang't jo de ekspresfracht betelje.

3) Hoe lang kin ik ferwachtsje om de stekproef te krijen?

Nei't jo de samplekosten betelje en ús befêstige bestannen stjoere, sille de samples yn 3-7 dagen klear wêze foar levering. De samples wurde fia ekspresje nei jo stjoerd en komme yn 3-7 wurkdagen. Jo kinne jo eigen express-akkount brûke of ús foarôf betelje as jo gjin akkount hawwe.

4) Hoe lang wurdt de hiele proseduere útwurke?

Nei't jo in bestelling pleatse, is de produksjetiid sawat 20-25 dagen. Wy hawwe 7 dagen nedich om al it spul te meitsjen, dan 15 dagen foar fabrikaazje.

5) Wat oer de transport- en leveringsdatum?

Normaal brûke wy ferstjoering om it guod te transprotearjen. It giet oer 7-25 dagen. It hinget ek ôf fan hokker lân en haven jo binne. It kin koarter wêze as jo it guod lykas Aziatyske stjoere moatte. As d'r wat needgefallen binne, kinne wy it guod fia air express stjoere, salang't jo de ferkearskosten betelje.

6) Binne jo hannelsbedriuw as fabrikant?

Wy binne profesjonele fabrikant. Wy hawwe net allinich ús arkfabryk, mar hawwe ek cemented carbide fabryk.

7) Wêr leit jo fabryk?

Wy binne fêstige yn Zhuzhou stêd, Hunan Provinsje., wolfraam carbid basis stêd fan Sina

8) Hoe lang kin ik ferwachtsje om de stekproef te krijen?

Nei't jo de samplekosten betelje en ús befêstige bestannen stjoere, sille de samples yn 3-7 dagen klear wêze foar levering. De samples wurde fia ekspresje nei jo stjoerd en komme yn 3-5 wurkdagen. Jo kinne jo eigen express-akkount brûke of ús foarôf betelje as jo gjin akkount hawwe.

9) Hoe sit it mei jo stock?

Wy hawwe produkten yn grutte kwantiteit op foarried, reguliere soarten en maten binne allegear op foarried.

10) Is fergees ferstjoeren mooglik?

Wy biede gjin fergese ferstjoertsjinst. Wy kinne hawwe in koarting as jo keapje in grutte kwantiteit produkten

Fiel dy frij Kontakt mei my op te nimmen :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co., Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

E-post: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688