- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Saghas

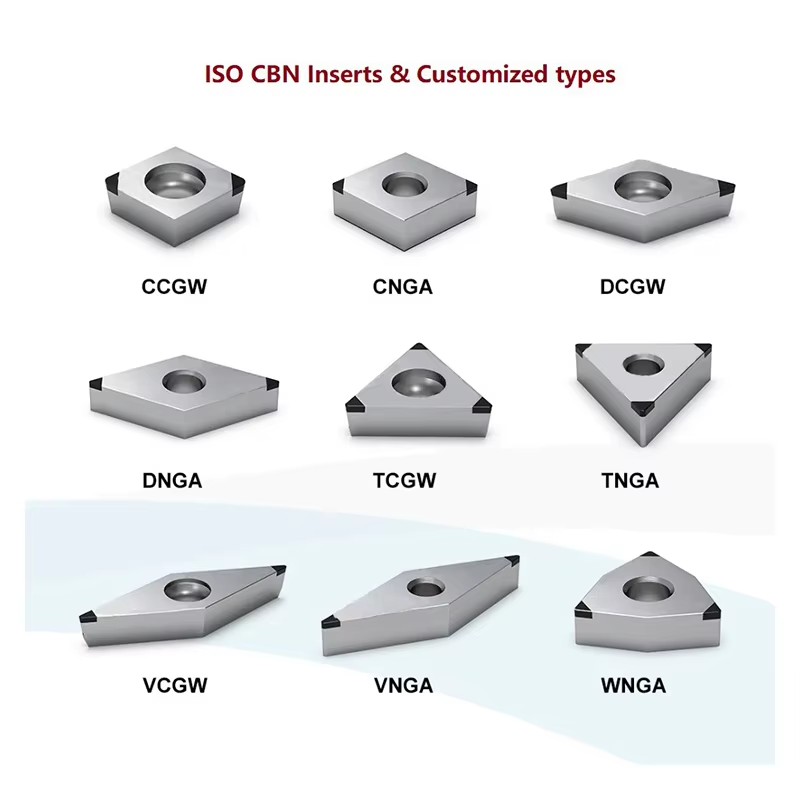

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

Welded cubic boron nitride blade

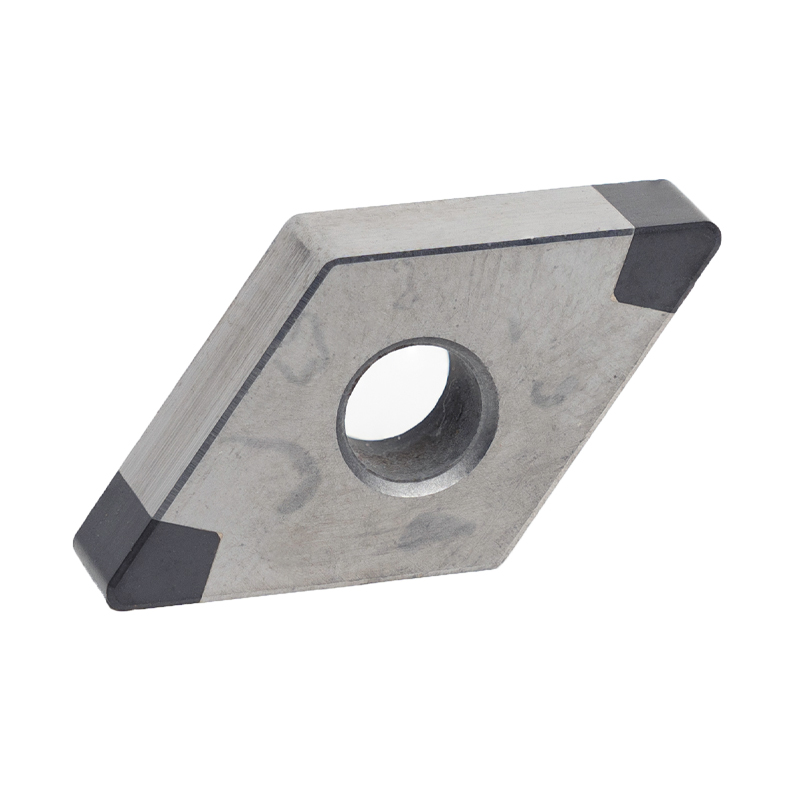

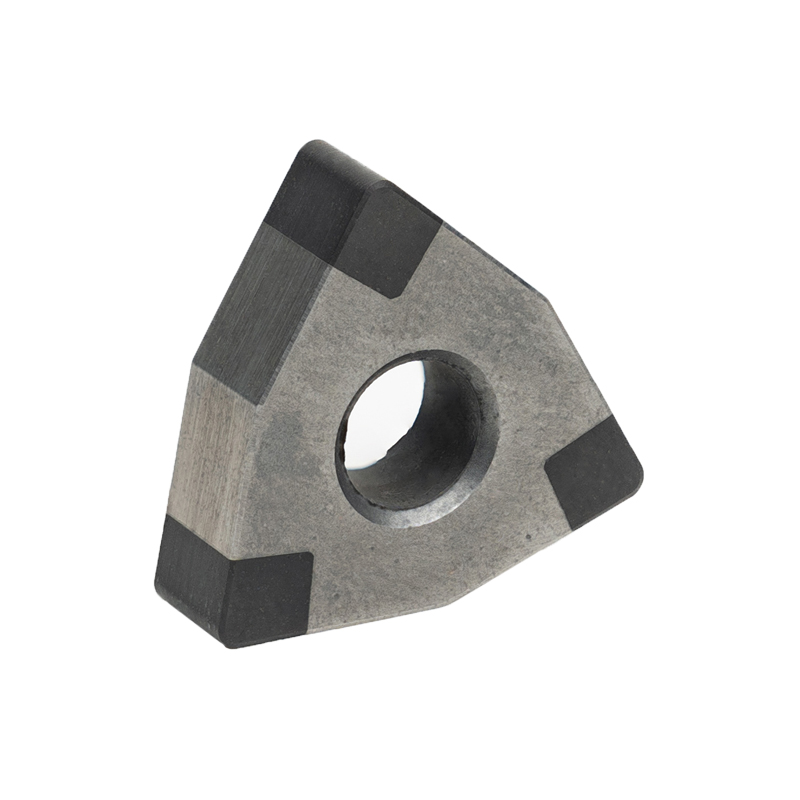

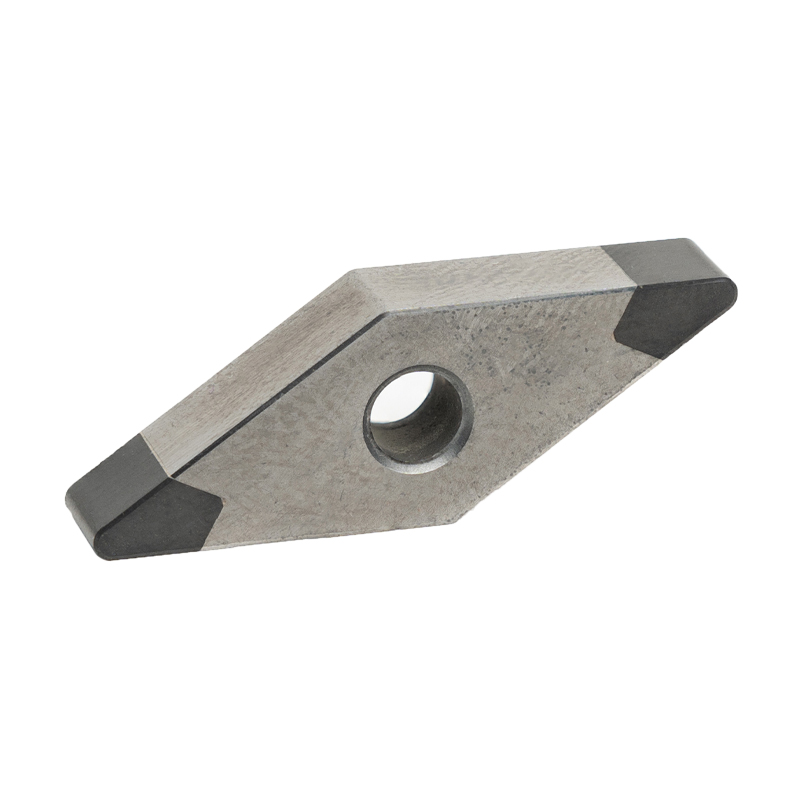

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

CC

1) Cathain is féidir liom an praghas a fháil?

Luaaimid de ghnáth laistigh de 24 uair an chloig tar éis dúinn d'fhiosrúchán a fháil.

2) Conas is féidir liom sampla a fháil chun do cháilíocht a sheiceáil?

Tar éis daingniú praghais, is féidir leat a cheangal ar shamplaí chun ár gcáilíocht a sheiceáil. Mura bhfuil uait ach sampla bán chun an dearadh agus cáilíocht an pháipéir a sheiceáil, cuirfimid sampla ar fáil duit saor in aisce, chomh fada agus a bheidh an lasta sainráite agat.

3) Cé chomh fada is féidir liom a bheith ag súil leis an sampla a fháil?

Tar éis duit an muirear samplach a íoc agus comhaid dheimhnithe a sheoladh chugainn, beidh na samplaí réidh le seachadadh i 3-7 lá. Seolfar na samplaí chugat trí express agus sroichfidh siad i 3-7 lá oibre. Is féidir leat do chuntas sainráite féin a úsáid nó sinn a réamhíocaíocht mura bhfuil cuntas agat.

4) Cá fhad a bheidh an nós imeachta iomlán á oibriú amach?

Tar éis duit ordú a dhéanamh, is é an t-am láimhseála táirgeachta thart ar 20-25 lá. Teastaíonn 7 lá uainn chun an t-ábhar go léir a ullmhú agus ansin 15 lá le haghaidh déantúsaíochta.

5) Cad mar gheall ar an dáta iompair agus seachadta?

De ghnáth úsáidimid loingsiú chun transprot an goods.It thart ar 7-25 days.It denpends freisin ar a coutry agus port atá tú. D'fhéadfadh sé a bheith níos giorra más gá duit a sheoladh ar na hearraí ar nós na hÁise. Má bhíonn roinnt éigeandálaí ann is féidir linn na hearraí a sheoladh trí aer mear, chomh fada agus a bheidh an costas tráchta in acmhainn agat.

6) An bhfuil tú ag trádáil cuideachta nó monaróir?

Táimid monaróir gairmiúil. Ní hamháin go bhfuil ár monarcha uirlisí ar úinéireacht againn, ach tá monarcha chomhdhúile cementáilte againn freisin.

7) Cá bhfuil do mhonarcha suite?

Táimid lonnaithe i gcathair Zhuzhou, Cúige Hunan ., Bunbhaile chomhdhúile tungstain na Síne

8) Cé chomh fada is féidir liom a bheith ag súil leis an sampla a fháil?

Tar éis duit an muirear samplach a íoc agus comhaid dheimhnithe a sheoladh chugainn, beidh na samplaí réidh le seachadadh i 3-7 lá. Seolfar na samplaí chugat trí express agus sroichfidh siad i 3-5 lá oibre. Is féidir leat do chuntas sainráite féin a úsáid nó sinn a réamhíocaíocht mura bhfuil cuntas agat.

9) Cad mar gheall ar do stoc?

Tá táirgí cainníochta móra againn i stoc, tá cineálacha agus méideanna rialta go léir i stoc.

10) An féidir loingseoireacht saor in aisce a dhéanamh?

Ní thairgimid seirbhís loingseoireachta saor in aisce. Is féidir linn lascaine a bheith againn má cheannaíonn tú líon mór táirgí

Ná bíodh drogall ort teagmháil a dhéanamh liom:

Aimee

Bainisteoir díolacháin

Zhuzhou Chuangde Cemented Carbide Co Ltd

215, building 1, International Students Pioneer Park,

Bóthar Taishan, Ceantar Tianyuan, Cathair Zhuzhou.

Ríomhphost: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688