- Materials: 100% raw material tungsten carbide

- HRC:55

- Flute:2/4

- Suitable for:Stainless steel/45# steel/tool steel/abrasive steel/carbon steel, etc.

Tuairisgeul

Product Detail:

This HRC55 2-flute carbide ball nose end mill represents the pinnacle of hard milling technology. It is expertly engineered to deliver exceptional surface finish and extended tool life when machining the toughest materials.

Uncompromising Performance on Hardened Steel: Designed specifically for materials with a hardness up to HRC55, this tool maintains its edge integrity and geometry in demanding applications. Its robust structure ensures minimal deflection and chatter, allowing you to achieve the highest standards of precision and surface quality on mold steels and hardened alloys.

Precision Ball Nose Geometry: The advanced ball nose design is optimized for 3D contouring and complex curved surface machining. It minimizes step-over marks and guarantees a consistently smooth and accurate profile, crucial for final part quality in the mold and die industry.

Built-in Efficiency: The 2-flute structure is specifically tailored for hard milling, providing maximum core rigidity and efficient heat dissipation. This design ensures superior chip evacuation and prevents thermal stress, allowing for higher cutting speeds and feed rates.

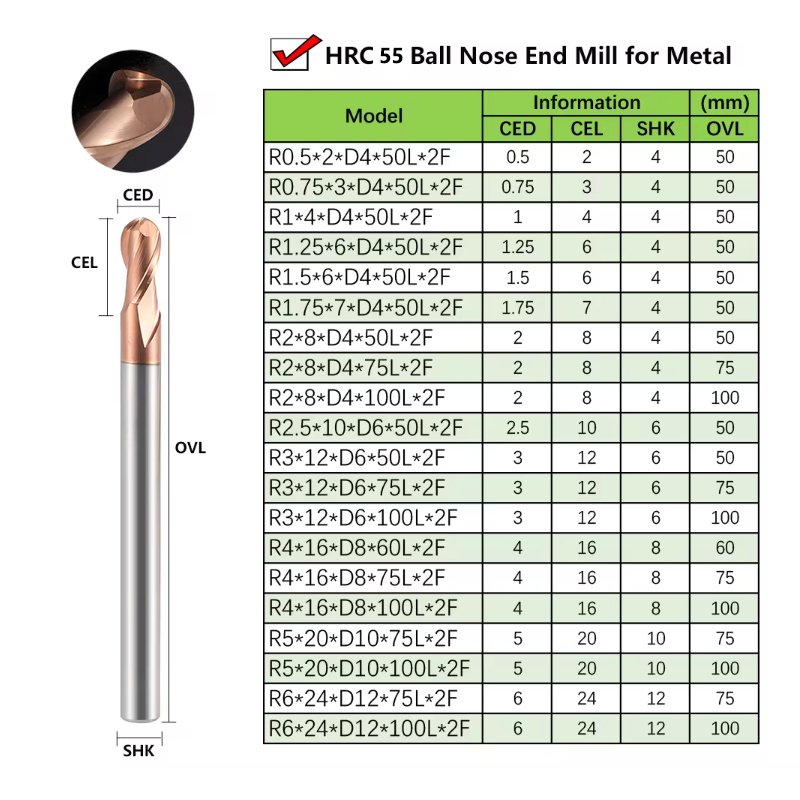

Product Specifications

These specifications detail the exact configuration of the D8x75mm HRC55 ball nose end mill.

Tool Type: Ball Nose End Mill / Radius End Mill

Number of Flutes: 2 Flutes

Maximum Hardness: HRC ≤ 55°

Shank Diameter (D1): 8mm (Nominal)

Cutting Diameter (D2): 8mm (Nominal)

Overall Length (L): 75mm (Medium-Long Reach)

Tool Material: Premium Micro-Grain Solid Carbide

Coating: High-Performance, High-Temperature Coating (e.g., AlTiN or similar)

Applicable Materials: Hardened Steel, Mold Steel, High-Hardness Alloys (e.g., 718, S136, NAK80 after heat treatment)

Primary Applications: Precision Finishing, Semi-Finishing, 3D Contouring, Medium-Depth Pocket Milling.

Large quantity with big discount.

Ceistean Cumanta

1) Cuin a gheibh mi a’ phrìs?

Mar as trice bidh sinn a 'toirt luaidh taobh a-staigh 24 uairean an dèidh dhuinn an rannsachadh agad fhaighinn.If tha thu gu math èiginneach gus a' phrìs fhaighinn, cuir fios thugainn no innis dhuinn anns a 'phost-d agad gus am bi sinn a' toirt aire do phrìomhachas rannsachaidh.

2) Ciamar a gheibh mi sampall gus sgrùdadh a dhèanamh air do chàileachd?

Às deidh dearbhadh prìsean, faodaidh tu iarraidh air sampallan gus ar càileachd a dhearbhadh. Ma tha feum agad air sampall bàn gus sgrùdadh a dhèanamh air dealbhadh agus càileachd pàipear, bheir sinn sampall dhut an-asgaidh, fhad ‘s a gheibh thu cothrom air a’ bhathar luath.

3) Dè cho fada 's as urrainn dhomh a bhith an dùil an sampall fhaighinn?

Às deidh dhut a ’chosgais sampall a phàigheadh agus faidhlichean dearbhte a chuir thugainn, bidh na sampallan deiseil airson an lìbhrigeadh ann an 3-7 latha. Thèid na sampallan a chuir thugad tro luath agus ruigidh iad ann an 3-7 latha-obrach. Faodaidh tu an cunntas luath agad fhèin a chleachdadh no ar pàigheadh ro-làimh mura h-eil cunntas agad.

4) Dè cho fada ‘s a tha am modh-obrach gu lèir air obrachadh a-mach?

Às deidh dhut òrdugh a chuir, tha an ùine làimhseachaidh toraidh timcheall air 20-25 latha. Feumaidh sinn 7 latha airson a h-uile stuth ullachadh agus an uairsin 15 latha airson saothrachadh.

5) Dè mu dheidhinn an ceann-latha còmhdhail agus lìbhrigidh?

Mar as trice bidh sinn a’ cleachdadh luchdan gus am bathar a thionndadh.Tha e timcheall air 7-25 latha.Tha e cuideachd an urra ri dè an coutry agus am port anns a bheil thu. Dh’ fhaodadh e a bhith nas giorra ma dh’fheumas tu am bathar a chuir mar Àisianach. Ma tha èiginn ann is urrainn dhuinn am bathar a chuir tro adhair luath, fhad ‘s a gheibh thu cosgais an trafaic.

6) An e companaidh malairt no neach-dèanamh a th’ annad?

Tha sinn nar neach-dèanamh proifeasanta. Chan e a-mhàin gu bheil ar factaraidh innealan againn, ach tha factaraidh carbide saimeant againn cuideachd.

7) Càite a bheil an fhactaraidh agad suidhichte?

Tha sinn suidhichte ann am baile-mòr Zhuzhou, Roinn Hunan ., baile tungsten carbide bonn ann an Sìona

8) Dè cho fada 's as urrainn dhomh a bhith an dùil an sampall fhaighinn?

Às deidh dhut a ’chosgais sampall a phàigheadh agus faidhlichean dearbhte a chuir thugainn, bidh na sampallan deiseil airson an lìbhrigeadh ann an 3-7 latha. Thèid na sampallan a chuir thugad tro luath agus ruigidh iad ann an 3-5 latha-obrach. Faodaidh tu an cunntas luath agad fhèin a chleachdadh no ar pàigheadh ro-làimh mura h-eil cunntas agad.

9) Dè mu dheidhinn do stoc?

Tha tòrr thoraidhean againn ann an stoc, tha seòrsaichean agus meudan cunbhalach uile ann an stoc.

10) A bheil luingearachd an-asgaidh comasach?

Chan eil sinn a’ tabhann seirbheis luingeis an-asgaidh. Faodaidh lasachadh a bhith againn ma cheannaicheas tu tòrr thoraidhean

Na bi leisg fios a chuir thugam:

Aimee

Manaidsear-reic

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

Rathad Taishan, Sgìre Tianyuan, Cathair Zhuzhou.

Post-d: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688