- Material:100% virgin tungsten carbide

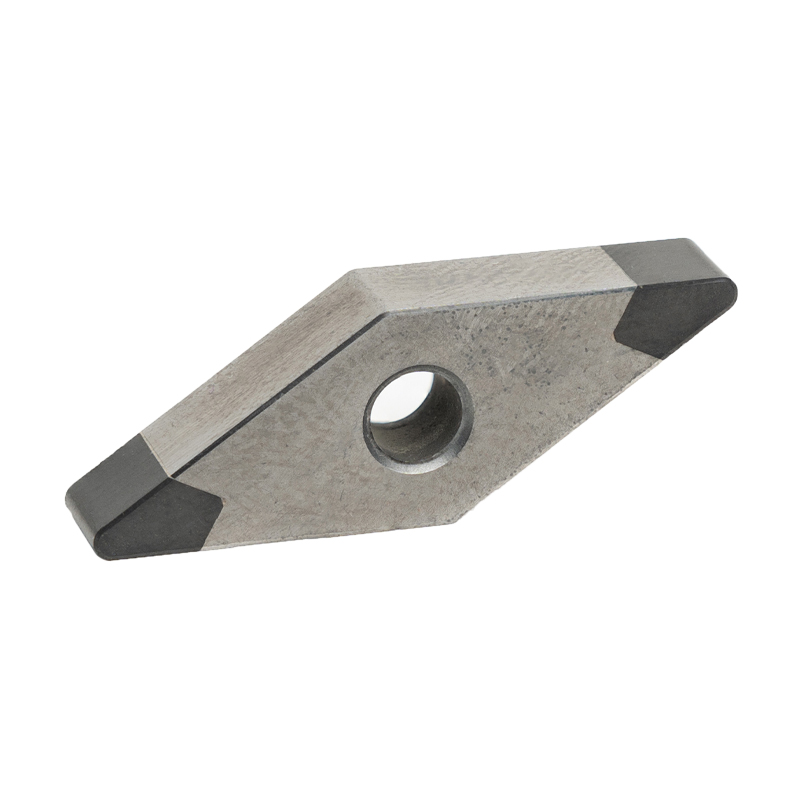

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Deskripsyon

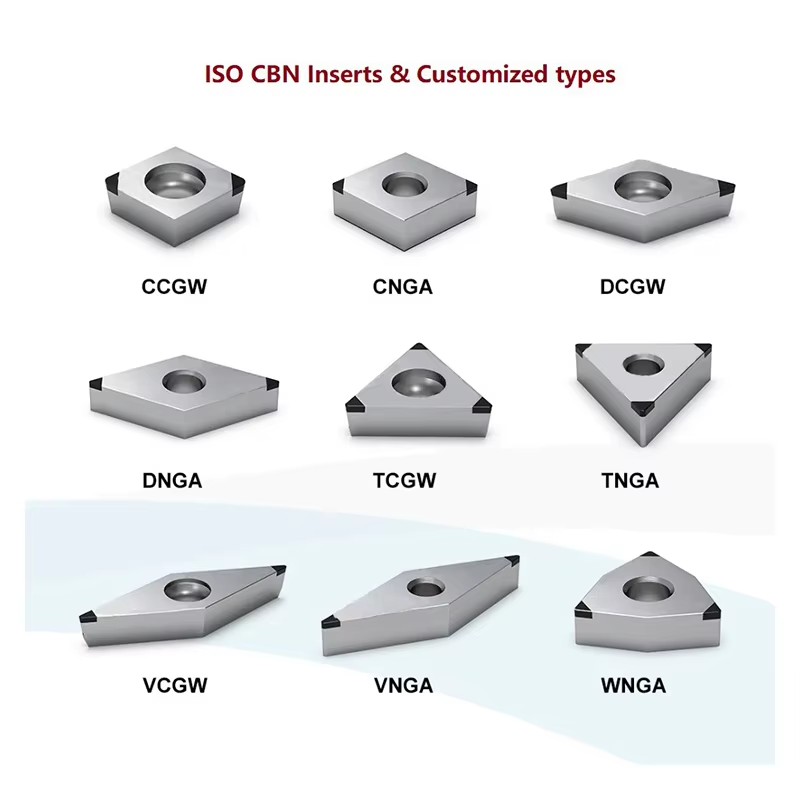

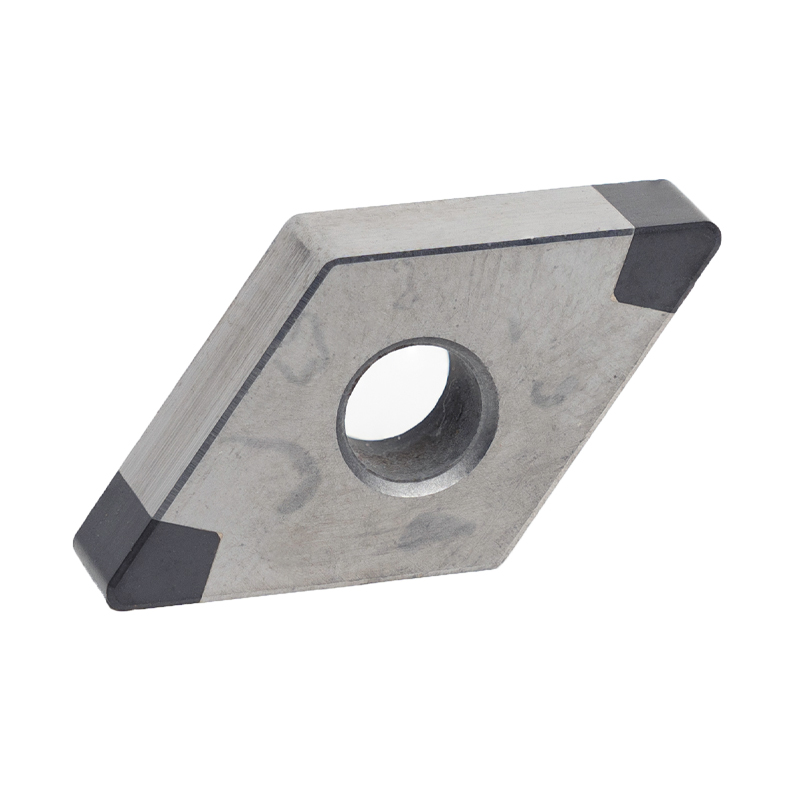

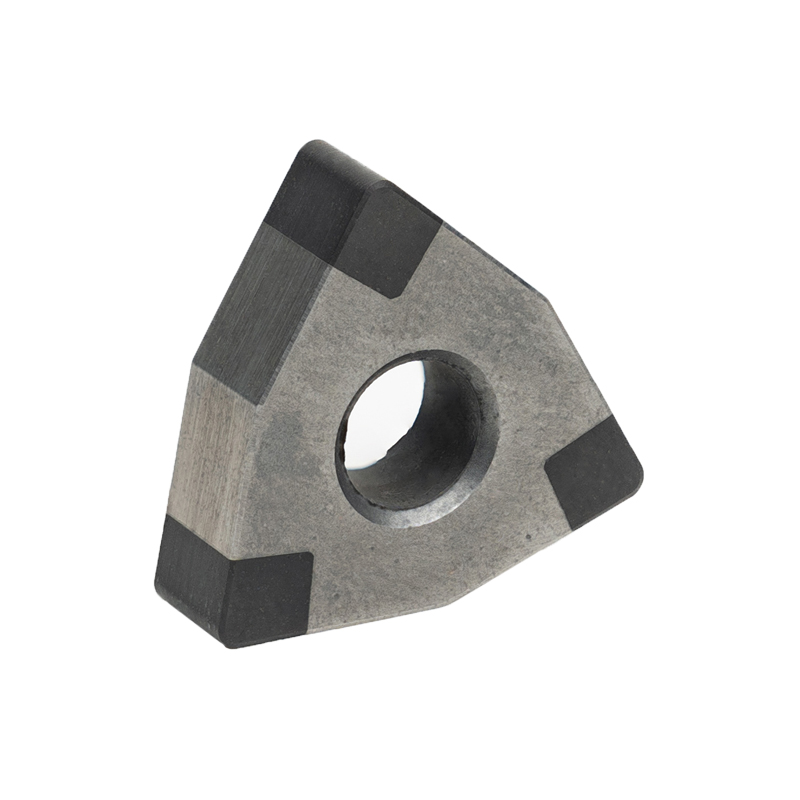

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

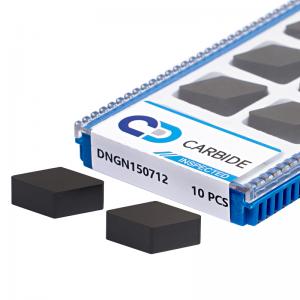

MOQ Quantity | 10pcs |

Introduction to CBN inserts

Welded cubic boron nitride blade

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

FAQ

1) Kilè mwen ka jwenn pri a?

Anjeneral nou site nan 24 èdtan apre nou jwenn demann ou an. Si ou trè ijan pou jwenn pri a, tanpri rele nou oswa di nou nan imèl ou pou nou konsidere priyorite rechèch ou an.

2) Kouman mwen ka jwenn yon echantiyon yo tcheke bon jan kalite ou a?

Apre konfimasyon pri, ou ka mande pou echantiyon yo tcheke bon jan kalite nou an. Si ou jis bezwen yon echantiyon vid yo tcheke konsepsyon an ak bon jan kalite papye, nou pral ba ou echantiyon pou gratis, osi lontan ke ou peye machandiz eksprime a.

3) Konbyen tan mwen ka espere jwenn echantiyon an?

Apre ou fin peye chaj echantiyon an epi voye nou konfime dosye, echantiyon yo pral pare pou livrezon nan 3-7 jou. Echantiyon yo pral voye ba ou atravè eksprime epi yo rive nan 3-7 jou travay. Ou ka itilize pwòp kont eksprime ou oswa peye nou davans si ou pa gen yon kont.

4) Konbyen tan pwosedi a tout antye ke yo te travay deyò?

Apre ou fin mete yon lòd, tan pwodiksyon an se sou 20-25 jou. Nou bezwen 7 jou pou nou prepare tout bagay yo answit 15 jou pou manifakti.

5) Ki sa ki sou transpò ak dat livrezon an?

Nòmalman nou itilize chajman transprot machandiz yo.Li se sou 7-25 jou.Li tou depann sou ki peyi ak pò ou ye.Li ta ka pi kout si ou bezwen voye machandiz yo tankou Azyatik. Si gen kèk ijans, nou ka voye machandiz yo atravè lè eksprime, osi lontan ke ou peye depans trafik la.

6) Èske ou komès konpayi oswa manifakti?

Nou se manifakti pwofesyonèl. Nou pa sèlman posede faktori zouti nou an, men tou, nou gen faktori carbure simante.

7) Ki kote faktori ou ye?

Nou sitiye nan vil Zhuzhou, pwovens Hunan., vil baz carbure tengstèn nan Lachin

8) Konbyen tan mwen ka espere jwenn echantiyon an?

Apre ou fin peye chaj echantiyon an epi voye nou konfime dosye, echantiyon yo pral pare pou livrezon nan 3-7 jou. Echantiyon yo pral voye ba ou atravè eksprime epi yo rive nan 3-5 jou travay. Ou ka itilize pwòp kont eksprime ou oswa peye nou davans si ou pa gen yon kont.

9) Kouman sou stock ou a?

Nou gen gwo kantite pwodwi nan stock, kalite regilye ak gwosè yo tout nan stock.

10) Èske gratis anbake posib?

Nou pa ofri sèvis anbake gratis. Nou ka gen yon rabè si ou achte yon gwo kantite pwodwi

Ou lib pou kontakte m:

Aimee

Manadjè lavant

Zhuzhou Chuangde Cemented Carbide Co Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Distri Tianyuan, Zhuzhou City.

Imèl: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688