- Material:100% virgin tungsten carbide

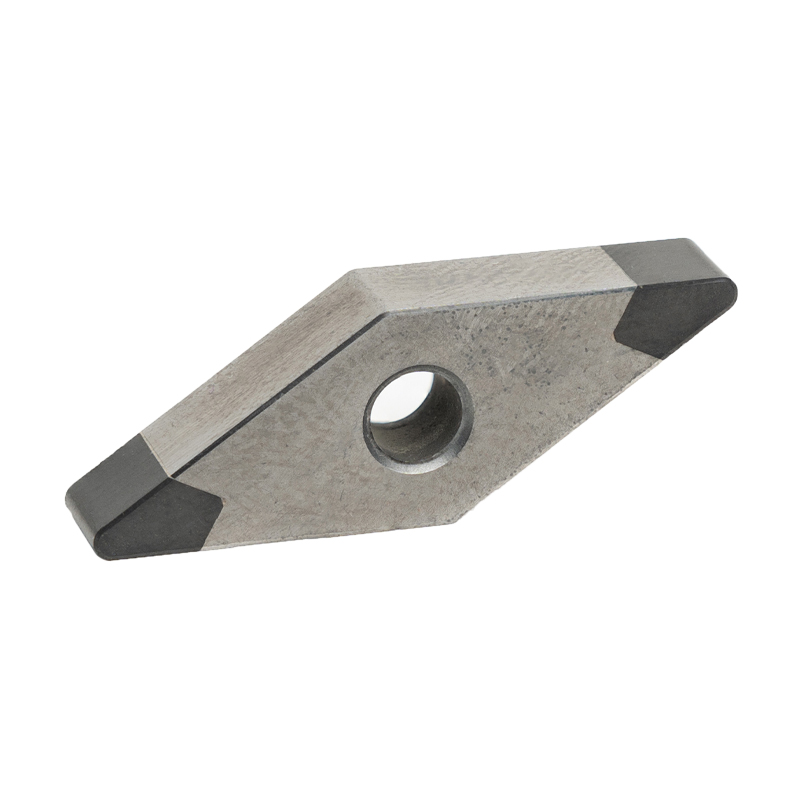

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Nkowa

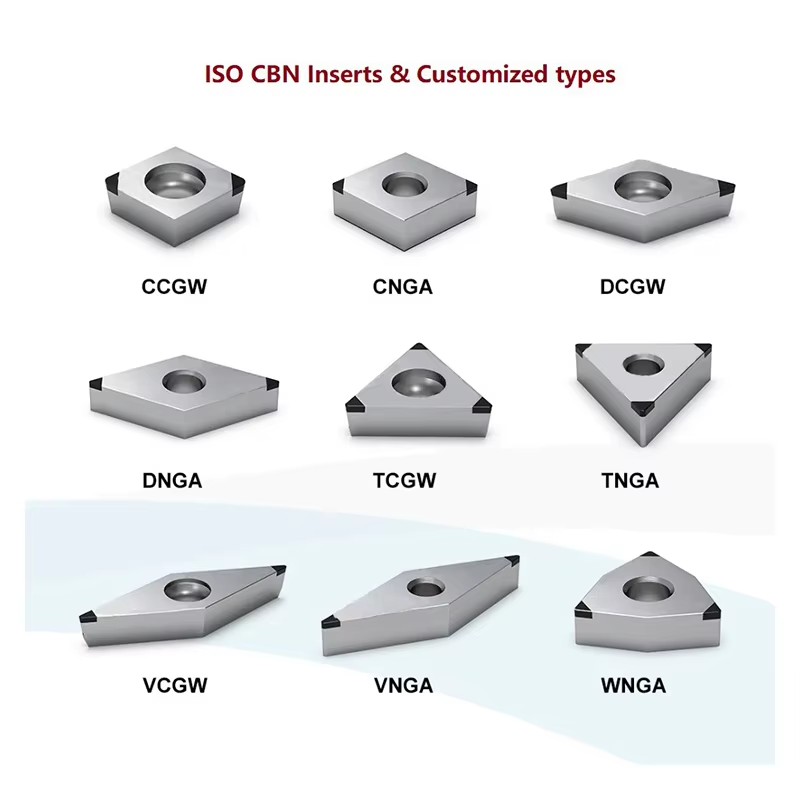

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

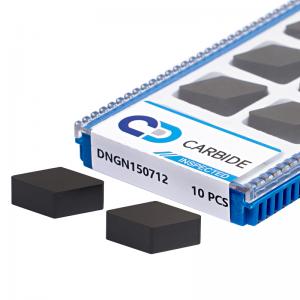

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

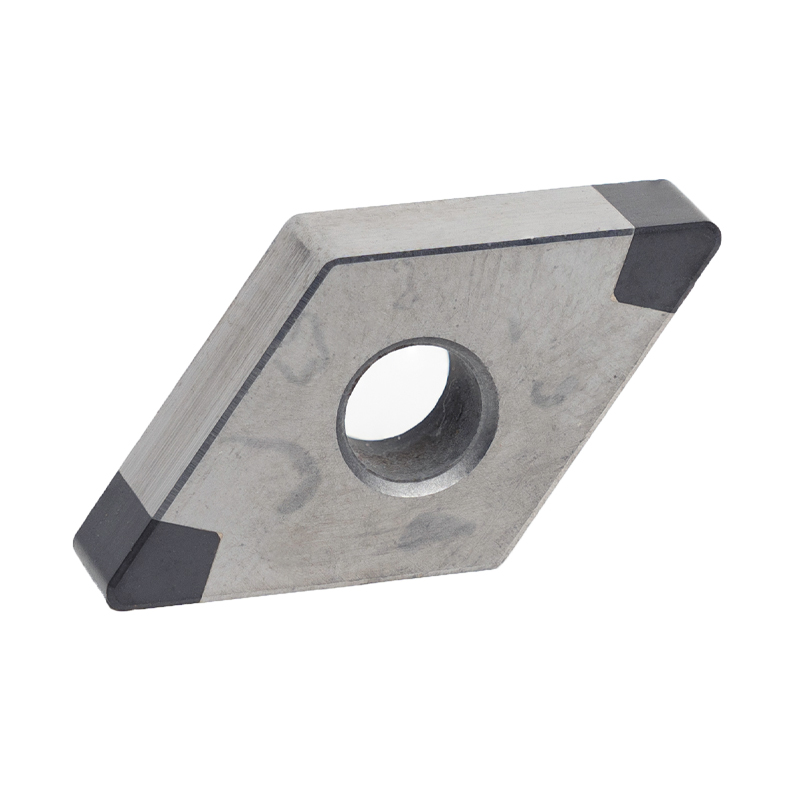

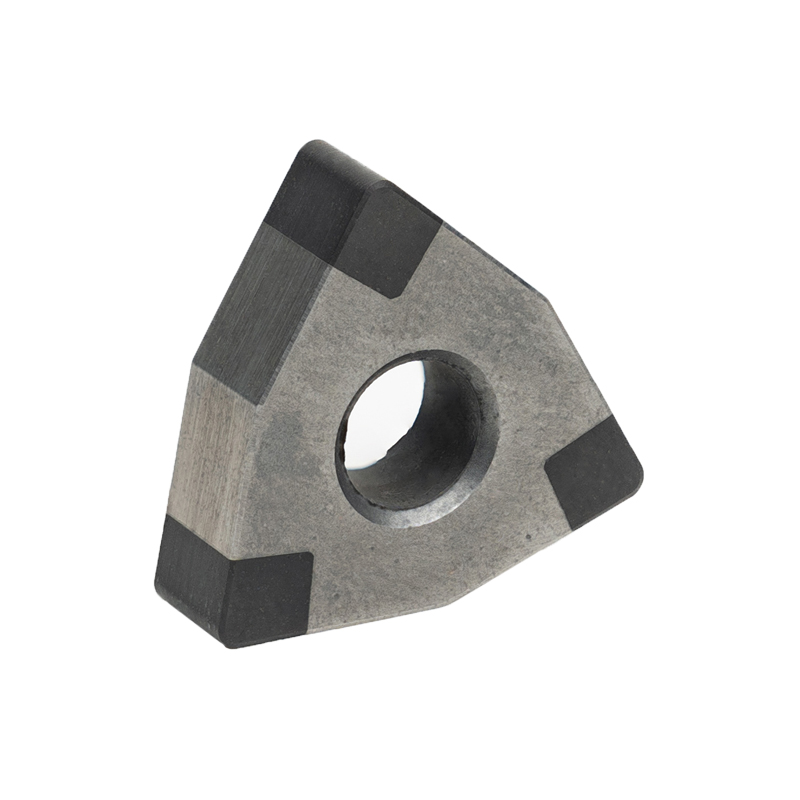

Welded cubic boron nitride blade

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

FAQ

1) Kedu mgbe m nwere ike nweta ọnụahịa ahụ?

Anyị na-ehotakarị n'ime awa 24 mgbe anyị nwetasịrị ajụjụ gị. Ọ bụrụ na ị dị ngwa ngwa iji nweta ọnụahịa ahụ, biko kpọọ anyị ma ọ bụ gwa anyị na email gị ka anyị wee leba anya na ajụjụ gị dị mkpa.

2) Kedu ka m ga-esi nweta sample iji lelee ogo gị?

Mgbe nkwenye ọnụahịa gasịrị, ị nwere ike ịchọ maka nlele iji lelee àgwà anyị. Ọ bụrụ na ịchọrọ naanị nlele oghere iji lelee imewe na ịdị mma akwụkwọ, anyị ga-enye gị nlele n'efu, ọ bụrụhaala na ị na-enweta ibu awara awara.

3) Ogologo oge ole ka m ga-atụ anya inweta sample?

Mgbe ịkwụchara ụgwọ nlele ma ziga anyị faịlụ ndị enwetara, ihe nlele ahụ ga-adị njikere maka nnyefe na ụbọchị 3-7. A ga-ezigara gị ihe nlele ahụ site na ngwa ngwa wee bịarute n'ime ụbọchị ọrụ 3-7. Ị nwere ike iji akaụntụ awara awara nke gị ma ọ bụ kwụọ anyị ụgwọ ma ọ bụrụ na ịnweghị akaụntụ.

4) Ogologo oge ole ka a na-arụ ọrụ ahụ dum?

Mgbe ị nyechara iwu, oge njikwa mmepụta ihe dị ka ụbọchị 20-25. Anyị chọrọ ụbọchị 7 iji dozie ihe niile wee 15 ụbọchị maka nrụpụta.

5) Kedu maka ụbọchị njem na nnyefe?

Dị ka ọ na-adịkarị, anyị na-eji mbupu na-ebufe ngwongwo ndị ahụ. Ọ bụ ihe dị ka ụbọchị 7-25. Ọ na-adaberekwa na ọdụ ụgbọ mmiri na ọdụ ụgbọ mmiri ị nọ. Ọ nwere ike ịdị mkpụmkpụ ma ọ bụrụ na ịchọrọ iziga ngwaahịa dị ka Asia. Ọ bụrụ na enwere ụfọdụ ihe mberede, anyị nwere ike izipu ngwongwo ndị ahụ site na ikuku ikuku, ọ bụrụhaala na ị na-akwụ ụgwọ ụgwọ okporo ụzọ.

6) Ị bụ ụlọ ọrụ azụmaahịa ma ọ bụ onye nrụpụta?

Anyị bụ ndị nrụpụta ọkachamara. Ọ bụghị naanị na anyị nwere ụlọ ọrụ akụrụngwa anyị, mana anyị nwekwara ụlọ ọrụ carbide cimented.

7) Ebee ka ụlọ ọrụ mmepụta ihe gị dị?

Anyị dị na Zhuzhou obodo, Hunan Province., Tungsten carbide isi obodo China.

8) Ogologo oge ole ka m ga-atụ anya inweta sample?

Mgbe ịkwụchara ụgwọ nlele ma ziga anyị faịlụ ndị enwetara, ihe nlele ahụ ga-adị njikere maka nnyefe na ụbọchị 3-7. A ga-ezigara gị ihe nlele ahụ site na ngwa ngwa wee bịarute n'ime ụbọchị ọrụ 3-5. Ị nwere ike iji akaụntụ awara awara nke gị ma ọ bụ kwụọ anyị ụgwọ ma ọ bụrụ na ịnweghị akaụntụ.

9) Kedu maka ngwaahịa gị?

Anyị nwere nnukwu ngwaahịa ngwaahịa na ngwaahịa, ụdị oge niile na nha niile dị na ngwaahịa.

10) Enwere ike mbupu n'efu?

Anyị anaghị enye ọrụ mbupu n'efu. Anyị nwere ike ịnwe mbelata ma ọ bụrụ na ịzụtara nnukwu ngwaahịa

Enwere onwe gị ịkpọtụrụ m:

Aimee

Onye njikwa ịre ahịa

Ụgwọ nke ụlọ ọrụ Zhuzhou Chuangde Cemented Carbide Co., Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Distrikti, City Zhuzhou .

Email: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

WhatsApp/wechat/Skype: 0086 13786352688