- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Katrangan

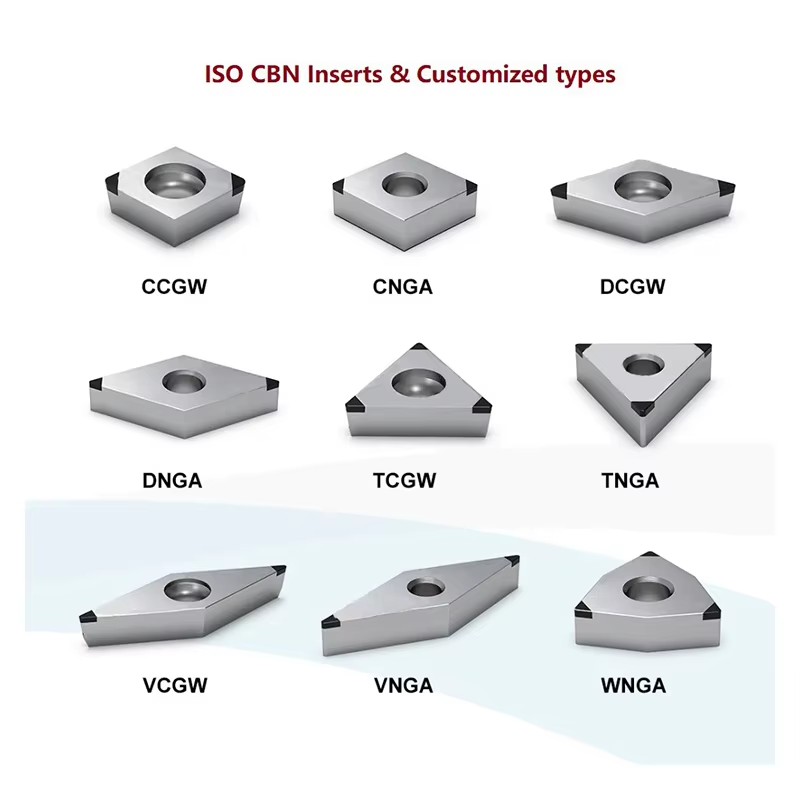

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

Welded cubic boron nitride blade

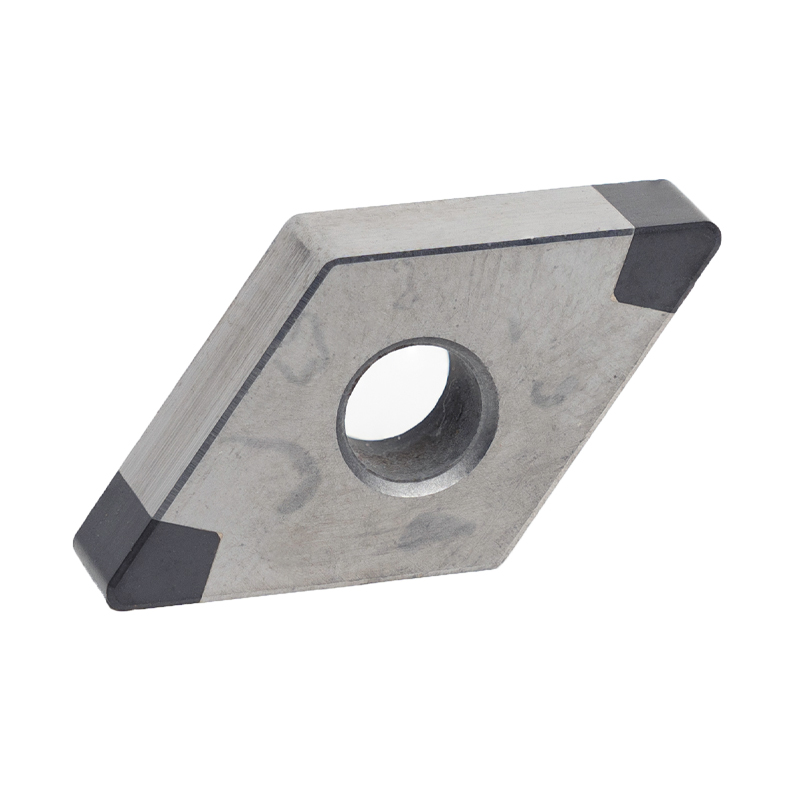

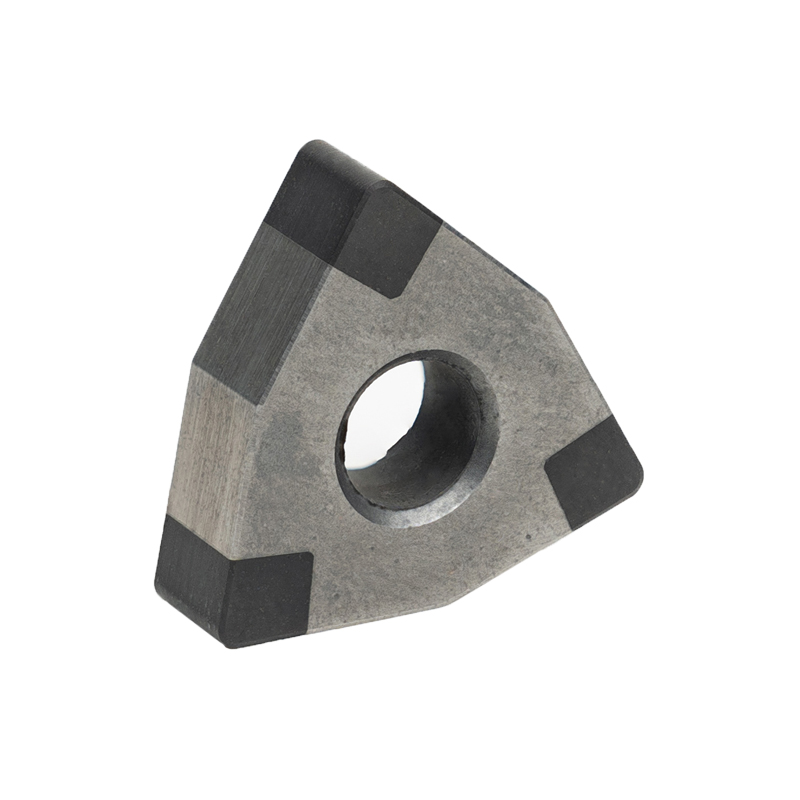

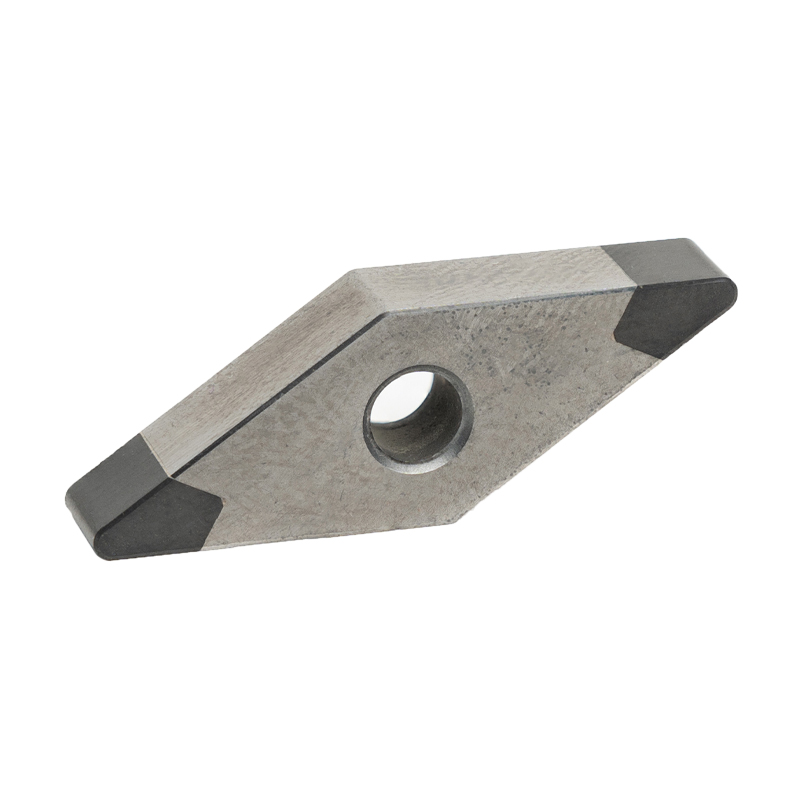

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

FAQ

1) Nalika aku bisa njaluk rega?

Kita biasane ngutip sajrone 24 jam sawise njaluk pitakon sampeyan.

2) Kepiye carane njaluk sampel kanggo mriksa kualitas sampeyan?

Sawise konfirmasi rega, sampeyan bisa njaluk conto kanggo mriksa kualitas kita. Yen sampeyan mung butuh sampel kosong kanggo mriksa desain lan kualitas kertas, kita bakal menehi conto gratis, anggere sampeyan bisa mbayar pengiriman ekspres.

3) Suwene aku bisa nyana kanggo njaluk sampel?

Sawise sampeyan mbayar biaya sampel lan ngirim file dikonfirmasi, conto bakal siap kanggo pangiriman ing 3-7 dina. Sampel bakal dikirim menyang sampeyan liwat ekspres lan teka ing 3-7 dina kerja. Sampeyan bisa nggunakake akun ekspres dhewe utawa prabayar yen sampeyan ora duwe akun.

4) Suwene suwene kabeh prosedur ditindakake?

Sawise sampeyan nggawe pesenan, wektu penanganan produksi kira-kira 20-25 dina. Kita butuh 7 dina kanggo nyiapake kabeh barang banjur 15 dina kanggo manufaktur.

5) Apa babagan transportasi lan tanggal pangiriman?

Biasane kita nggunakake kiriman kanggo transprot barang. Iku bab 7-25 dina. Iku uga denpends kang coutry lan port sampeyan.Bisa dadi luwih cendhek yen sampeyan kudu ngirim barang kaya Asia. Yen ana sawetara kahanan darurat, kita bisa ngirim barang liwat ekspres udara, anggere sampeyan bisa mbayar biaya lalu lintas.

6) Apa sampeyan perusahaan dagang utawa pabrikan?

Kita minangka produsen profesional. Kita ora mung duwe pabrik alat, nanging uga duwe pabrik karbida semen.

7) Where is pabrik Panjenengan?

Kita dumunung ing kutha Zhuzhou, Provinsi Hunan., Kutha basis tungsten karbida China

8) Suwene aku bisa nyana kanggo njaluk sampel?

Sawise sampeyan mbayar biaya sampel lan ngirim file dikonfirmasi, conto bakal siap kanggo pangiriman ing 3-7 dina. Sampel bakal dikirim menyang sampeyan liwat ekspres lan teka ing 3-5 dina kerja. Sampeyan bisa nggunakake akun ekspres dhewe utawa prabayar yen sampeyan ora duwe akun.

9) Kepiye babagan saham sampeyan?

We duwe produk jumlahe akeh ing Simpenan, jinis biasa lan ukuran kabeh ing Simpenan.

10) Apa pengiriman gratis bisa?

Kita ora nawakake layanan pengiriman gratis. Kita bisa duwe diskon yen sampeyan tuku produk jumlahe akeh

Bebas bae kanggo hubungi kula:

Aimee

Manajer sales

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Distrik, Zhuzhou City.

Email: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688