- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Whakaaturanga

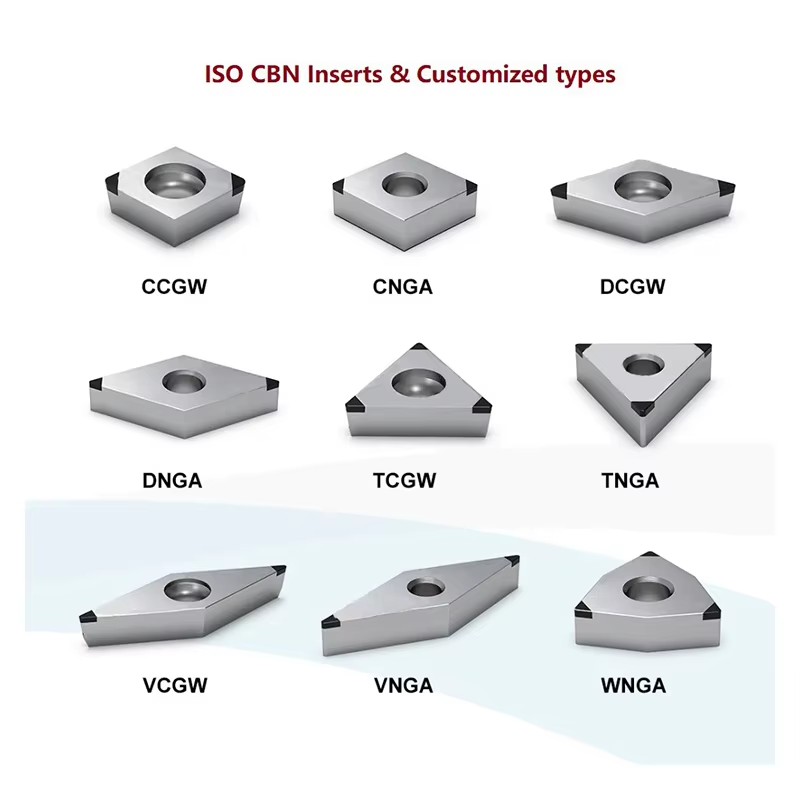

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

Welded cubic boron nitride blade

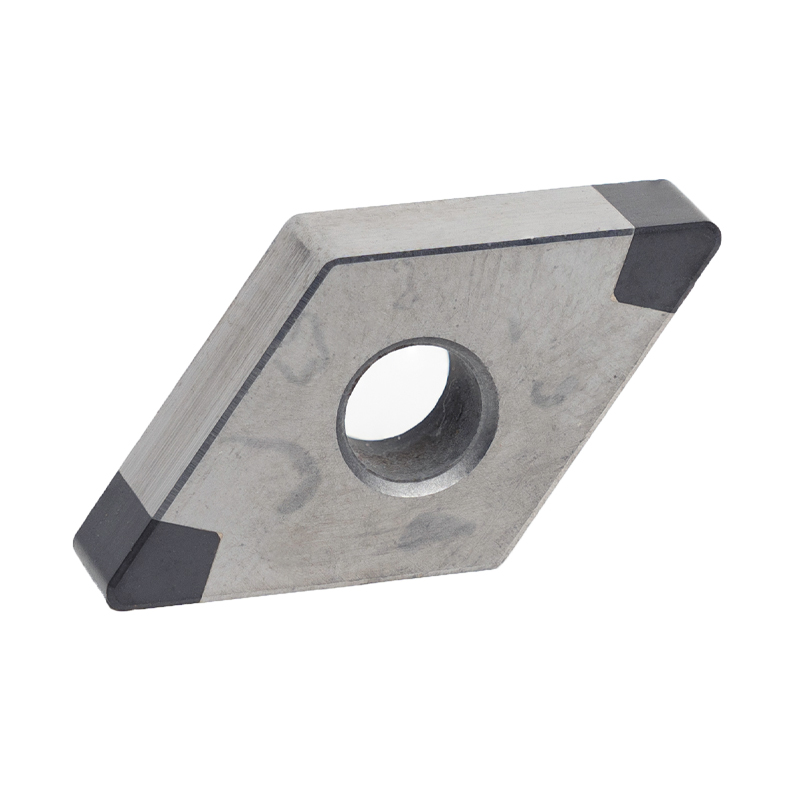

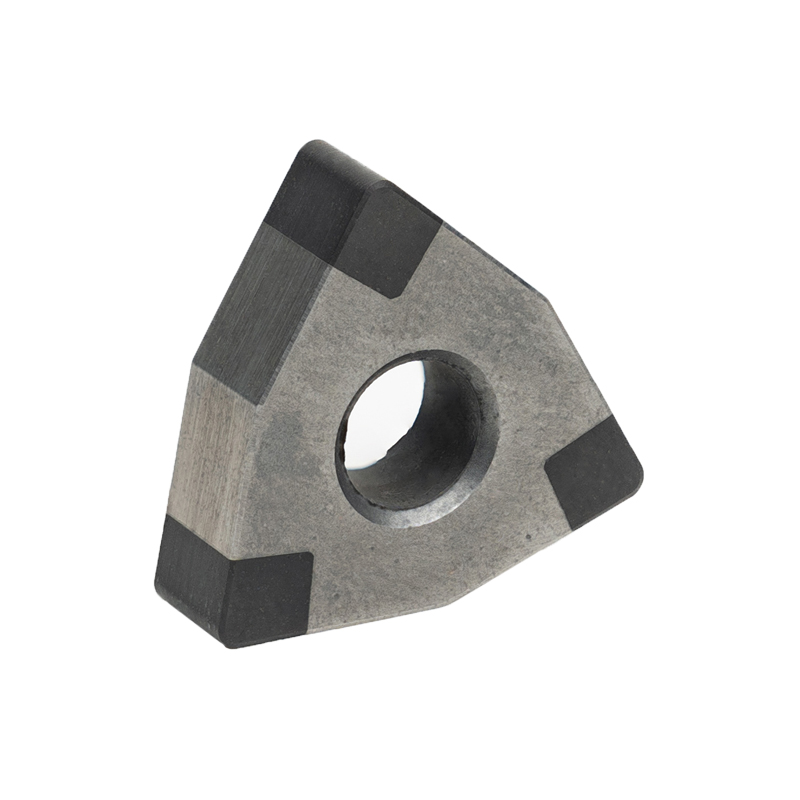

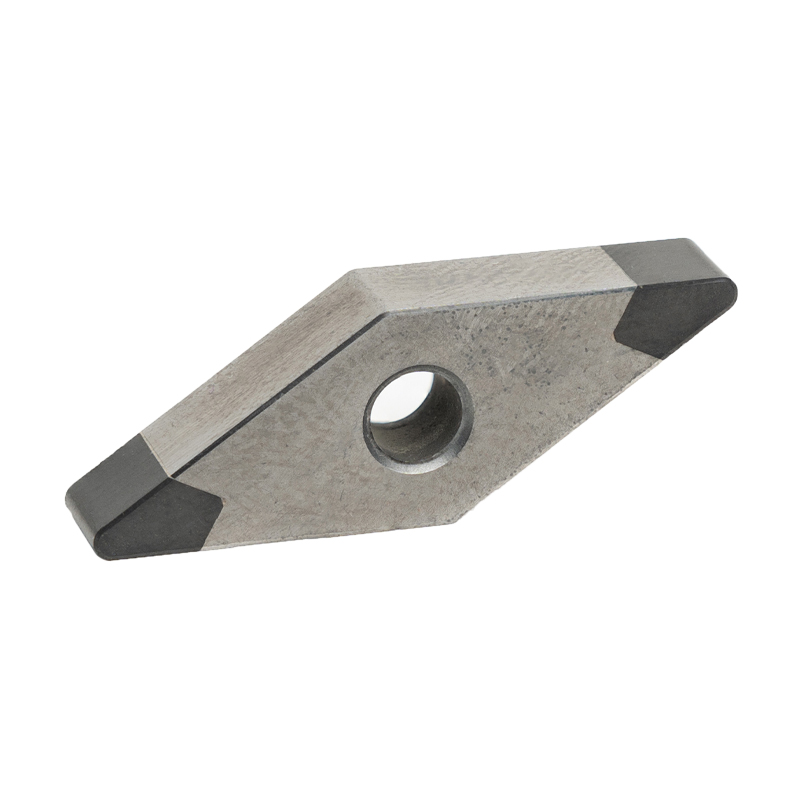

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

FAQ

1) Ahea e taea ai e au te utu?

I te nuinga o nga wa ka korero matou i roto i nga haora 24 i muri i to maatau patai.Mehemea kei te tino akiaki koe ki te tiki i te utu, waea mai ki a maatau, korero mai ranei i to imeera kia whai whakaaro ai matou ki to patai.

2) Me pehea e taea ai e au he tauira hei tirotiro i to kounga?

I muri i te haamauraa utu, ka taea e koe te tono mo nga tauira hei tirotiro i to maatau kounga. Mena ka hiahia noa koe ki tetahi tauira waatea hei tirotiro i te hoahoa me te kounga o te pepa, ka tukuna atu e matou he tauira mo te kore utu, i te mea ka taea e koe te utu mo te utu utu.

3) Kia pehea te roa ka tumanako ahau ki te tiki i te tauira?

I muri i to utu i te utu tauira me te tuku mai i nga konae kua whakamanahia, ka rite nga tauira mo te tuku i nga ra 3-7. Ka tukuna atu nga tauira ki a koe ma te korero ka tae mai i nga ra mahi 3-7. Ka taea e koe te whakamahi i to ake putea korero, utu tomua ranei ki a maatau mena kaore he putea.

4) Kia pehea te roa o te mahi katoa?

I muri i to tuunga ota, ko te waa whakahaere mo te 20-25 ra. Me 7 nga ra ki te whakarite i nga mea katoa ka 15 nga ra mo te hanga.

5) He aha te waa kawe me te ra tuku?

Ko te tikanga ka whakamahia e matou he tuku ki te whakawhiti i nga taonga. Ko te 7-25 nga ra. Ka whakawhirinaki ano ki tehea whenua me te tauranga kei a koe. He poto ake mena ka hiahia koe ki te tuku i nga taonga penei i a Ahia. Mena he ohorere ka taea e matou te tuku i nga taonga ma te rererangi rererangi, mena ka utua e koe nga utu hokohoko.

6) He kamupene hokohoko koe, he kaihanga ranei?

He kaihanga ngaio matou. Ehara i te mea kei a matou anake o maatau wheketere taputapu, engari he wheketere carbide cimented hoki.

7) Kei hea to wheketere?

Kei roto matou i te taone nui o Zhuzhou, te Porowini o Hunan., te taone nui o Haina

8) Kia pehea te roa ka tumanako ahau ki te tiki i te tauira?

I muri i to utu i te utu tauira me te tuku mai i nga konae kua whakamanahia, ka rite nga tauira mo te tuku i nga ra 3-7. Ka tukuna atu nga tauira ki a koe ma te korero ka tae mai i nga ra mahi 3-5. Ka taea e koe te whakamahi i to ake putea korero, utu tomua ranei ki a maatau mena kaore he putea.

9) Me pehea to taonga?

He maha nga hua kei roto i nga taonga, ko nga momo me nga rahi kei roto katoa.

10) Ka taea te tuku kore utu?

Kaore matou e tuku ratonga kaipuke kore utu. Ka taea e taatau te utu mena ka hoko koe i nga hua nui

Tena koa whakapiri mai ki ahau:

Aimee

Kaiwhakahaere hokohoko

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Īmēra: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688