- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Deskrizzjoni

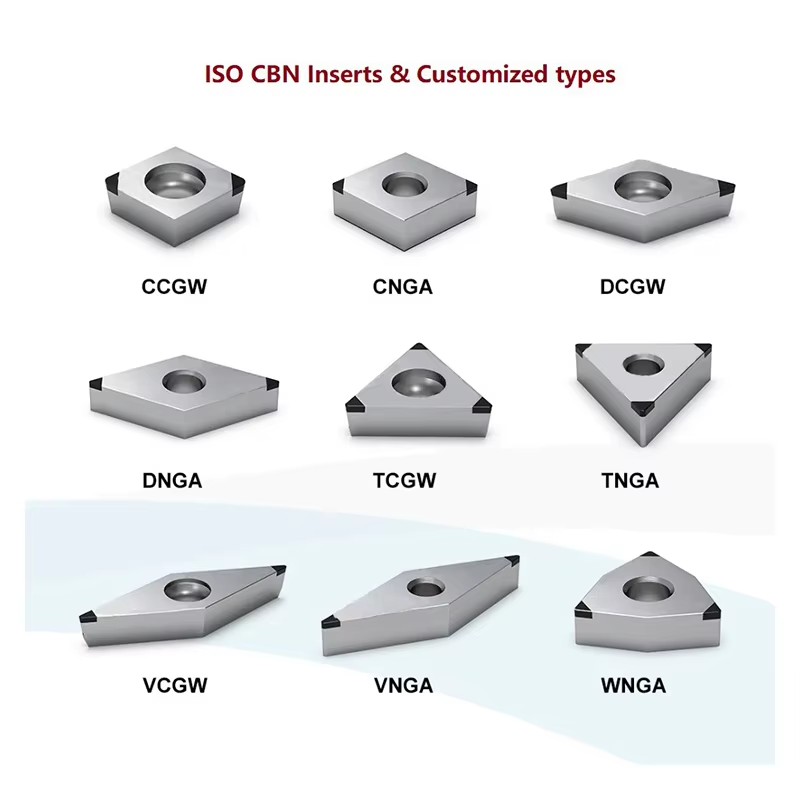

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

Welded cubic boron nitride blade

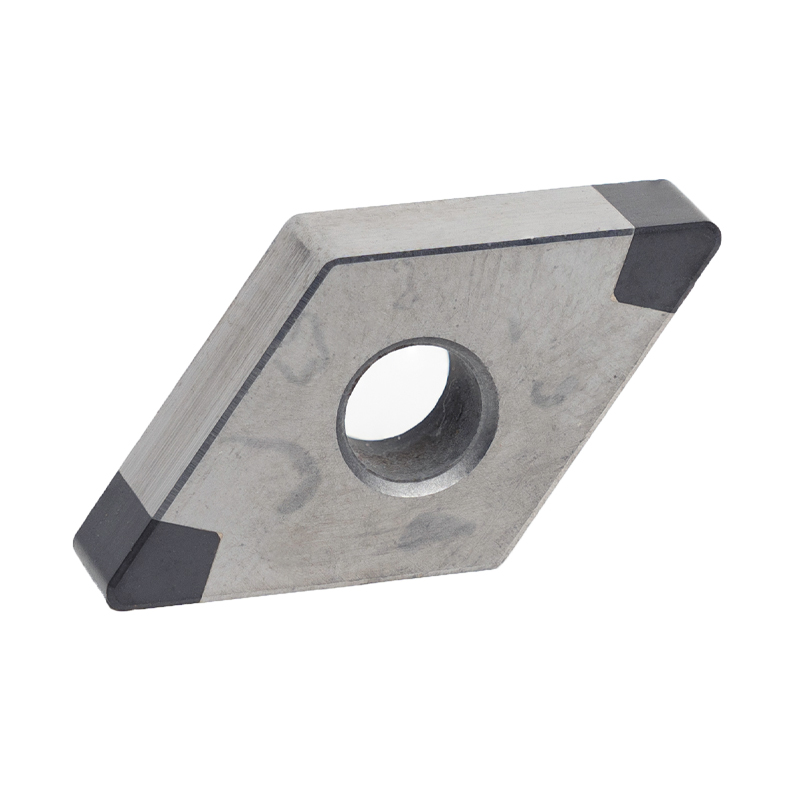

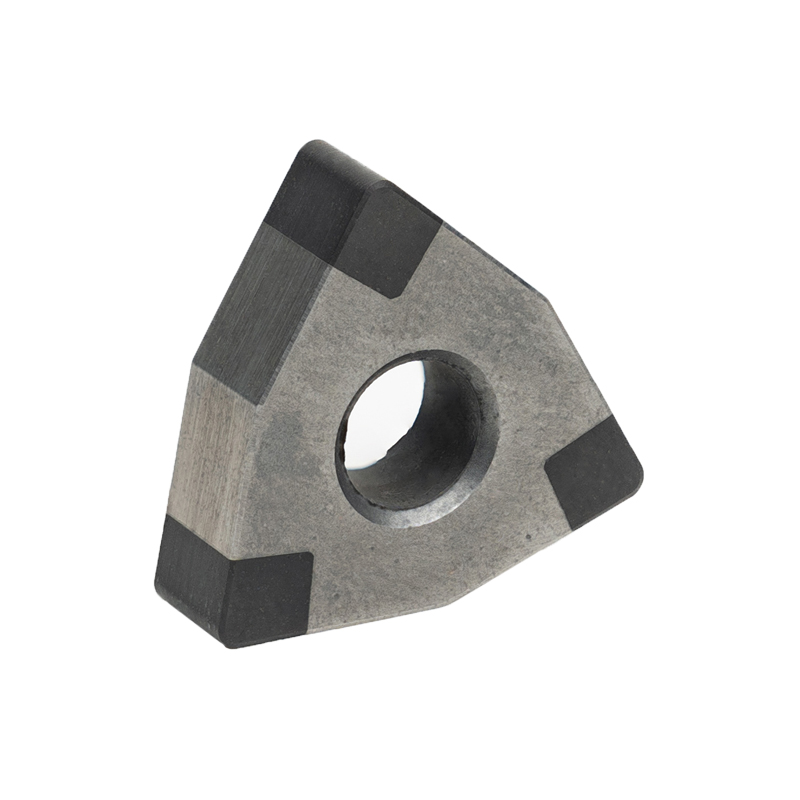

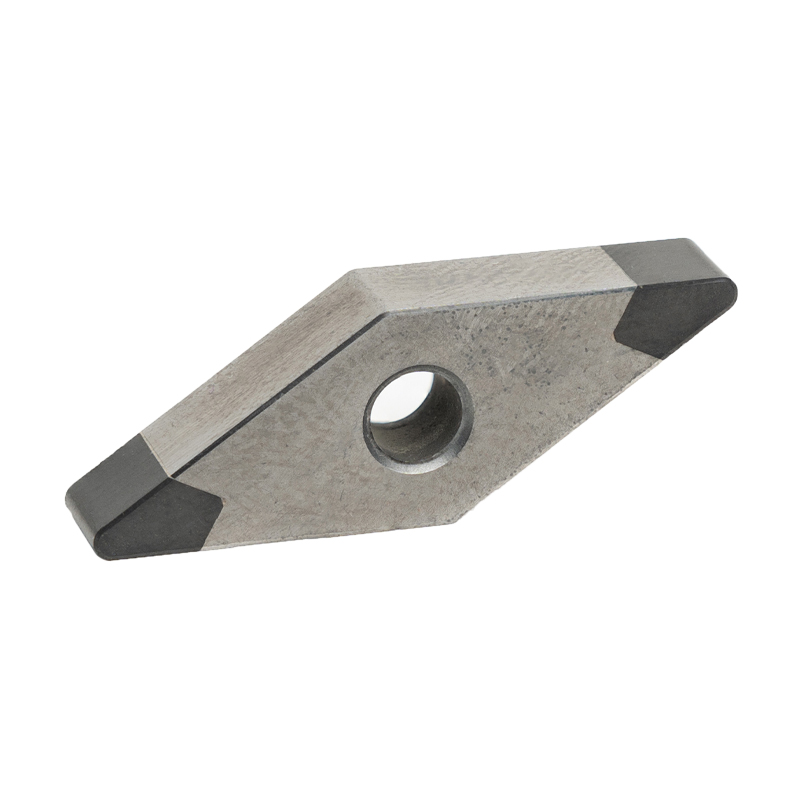

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

FAQ

1) Meta nista 'nikseb il-prezz?

Normalment nikkwotaw fi żmien 24 siegħa wara li nġibu l-inkjesta tiegħek. Jekk int urġenti ħafna biex tikseb il-prezz, jekk jogħġbok ċempelna jew għidilna fl-email tiegħek sabiex inqisu l-prijorità tal-inkjesta tiegħek.

2) Kif nista 'nikseb kampjun biex niċċekkja l-kwalità tiegħek?

Wara l-konferma tal-prezz, tista 'teħtieġ li l-kampjuni jiċċekkjaw il-kwalità tagħna. Jekk għandek bżonn biss kampjun vojt biex tiċċekkja d-disinn u l-kwalità tal-karta, aħna nipprovdulek kampjun b'xejn, sakemm taffordja l-merkanzija espressa.

3) Kemm nista' nistenna li nikseb il-kampjun?

Wara li tħallas il-ħlas tal-kampjun u tibgħatilna fajls ikkonfermati, il-kampjuni jkunu lesti għall-kunsinna fi żmien 3-7 ijiem. Il-kampjuni jintbagħtulek permezz express u jaslu fi 3-7 ijiem tax-xogħol. Tista' tuża l-kont espress tiegħek stess jew tħallasna minn qabel jekk ma jkollokx kont.

4) Kemm idum il-proċedura kollha li qed tinħadem?

Wara li tagħmel ordni, il-ħin tal-immaniġġjar tal-produzzjoni huwa ta 'madwar 20-25 jum. Għandna bżonn 7 ijiem biex nippreparaw l-għalf kollu imbagħad 15-il jum għall-manifattura.

5) Xi ngħidu dwar it-trasport u d-data tal-kunsinna?

Normalment nużaw il-vjaġġ bil-baħar biex jittrasportaw il-merkanzija. Huwa ta 'madwar 7-25 ġurnata. Jiddependi wkoll minn liema pajjiż u port int. Jista' jkun iqsar jekk għandek bżonn tibgħat l-oġġetti bħall-Asja. Jekk ikun hemm xi emerġenzi nistgħu nibagħtu l-merkanzija permezz ta 'air express, sakemm taffordja l-ispiża tat-traffiku.

6) Int kumpanija kummerċjali jew manifattur?

Aħna manifattur professjonali. Aħna mhux biss tippossjedi l-fabbrika tal-għodod tagħna, iżda għandna wkoll fabbrika tal-karbur tas-siment.

7) Fejn tinsab il-fabbrika tiegħek?

Aħna jinsabu fil-belt ta 'Zhuzhou, Provinċja ta' Hunan., belt bażi tal-karbur tat-tungstenu taċ-Ċina

8) Kemm nista' nistenna li nikseb il-kampjun?

Wara li tħallas il-ħlas tal-kampjun u tibgħatilna fajls ikkonfermati, il-kampjuni jkunu lesti għall-kunsinna fi żmien 3-7 ijiem. Il-kampjuni jintbagħtulek permezz express u jaslu fi 3-5 ijiem tax-xogħol. Tista' tuża l-kont espress tiegħek stess jew tħallasna minn qabel jekk ma jkollokx kont.

9) Kif dwar l-istokk tiegħek?

Għandna prodotti ta 'kwantità kbira fl-istokk, tipi u daqsijiet regolari huma kollha fl-istokk.

10) Huwa possibbli tbaħħir b'xejn?

Aħna ma noffrux servizz ta 'tbaħħir b'xejn. Nistgħu jkollna skont jekk tixtri prodotti ta 'kwantità kbira

Ħossok liberu li tikkuntattjani:

Aimee

Manager tal-bejgħ

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Distrett Tianyuan, Belt Zhuzhou.

Email: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688