Momwe mungasankhire ma CNC pazinthu zolimbitsa thupi

Pamunda wamakina amakina, kukonza zinthu zolimba (monga chitsulo chouma komanso chitsulo chovuta kwambiri) kwakhala vuto laukadaulo nthawi zonse. Zipangizozi zimakhala ndi kuvuta kwambiri komanso nyonga, kuyika zofuna kwambiri pakudula zida. Nkhaniyi imagwiritsa ntchito CD20255h Precnies infiction monga chitsanzo choperekera zida zoyeserera zachitsulo, zophimba magawo anayi: zakuthupi, ziphunzitso, zowerengera, maphunziro enieni padziko lapansi.

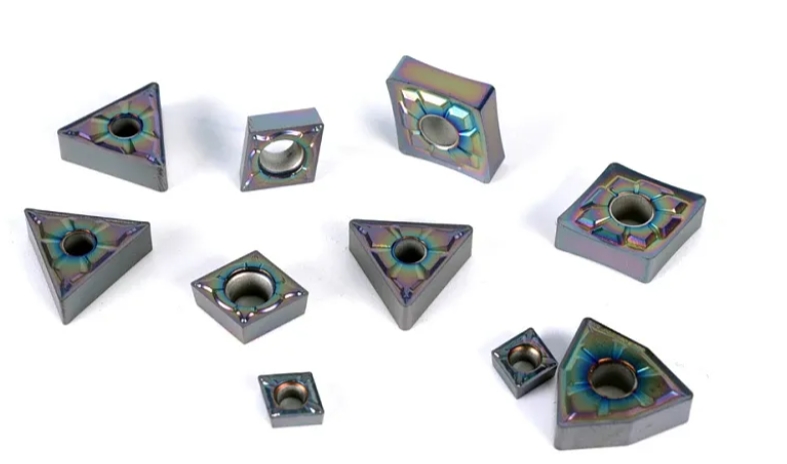

1. Ikani zinthu: kuphatikiza bwino kwambiri kwa magawo apamwamba kwambiri ndi kusonkhanitsidwa

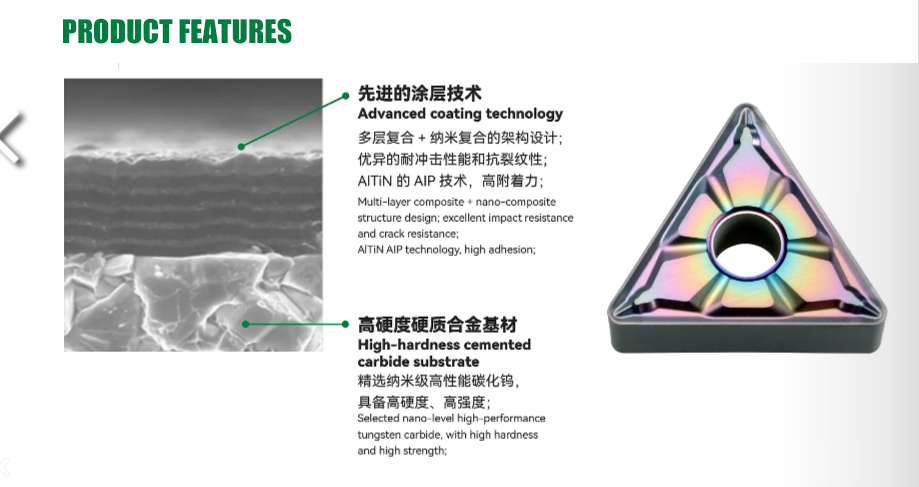

Kupikisana kwa CD2025h kumagona paukadaulo wa zinthu:

Kuuma kwambiri kwa carbidis kumangidwa: Kupangidwa kuchokera ku cangster Cangstey Cangside Worside, imaphatikizira kuuma kwakukulu ndi mphamvu yayikulu, kupereka maziko olimba a chitsulo cholimba.

UTHENGA WABWINO PVD:

Mapangidwe ambiri osanjikaka + Nano-kapangidwe kake

Kutsutsana Kwambiri ndi Kukana Kukana

Imagwiritsa ntchito ukadaulo wa Aitin a Aitin a Mode Wamphamvu Wophatikiza

Kuphatikizika kumeneku kumapangitsa oph120 makamaka makamaka chifukwa chogwiritsa ntchito zida zolimba ngati chitsimikizo ngati chitsulo cha skd11, monganso chitsulo cha STD11.

UTHENGA WABWINO WABWINO WA GULEO: KULENGA KWAULERE KWAULERE

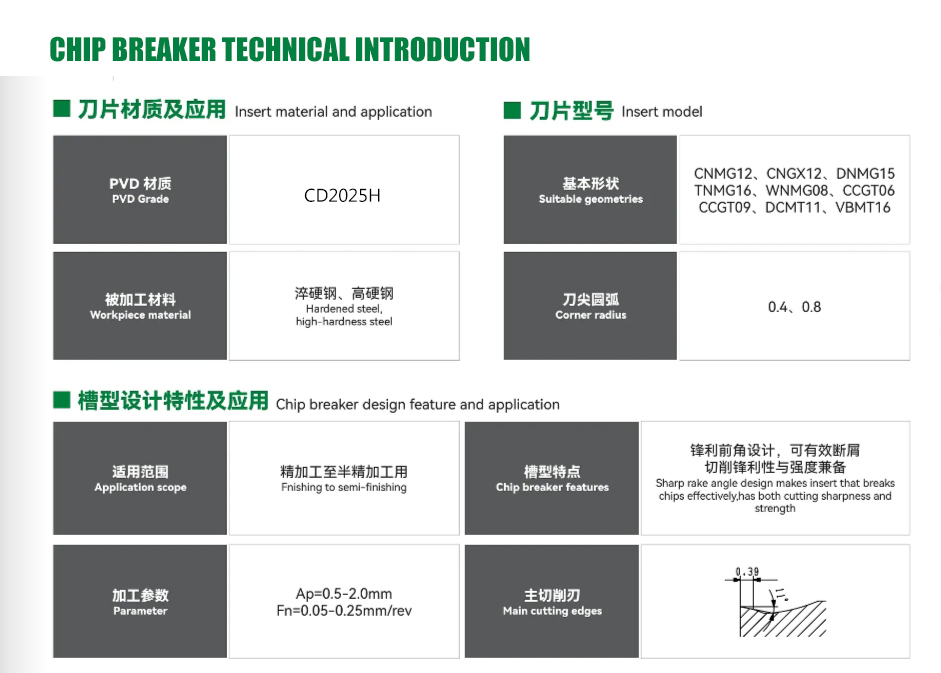

OHIN GRIG COBOROR Iminor Indust imapereka ma CD2025h ndikuyika magwiridwe antchito apadera:

![]()

3..

Malinga ndi mfundo za ISO, machitidwe a CD2025h ali motere:

Zofunikira:

Kulimbana Kwambiri ndi Kutopa

Oyenera kukhazikika kwambiri mpaka 45-60hrc

Kudulidwa kwakukulu kokweza (30-80 m / min), kusintha malinga ndi zochitika zina

4. Gawo lenileni la Dziko Lonse: Kugwiritsa ntchito mankhwala

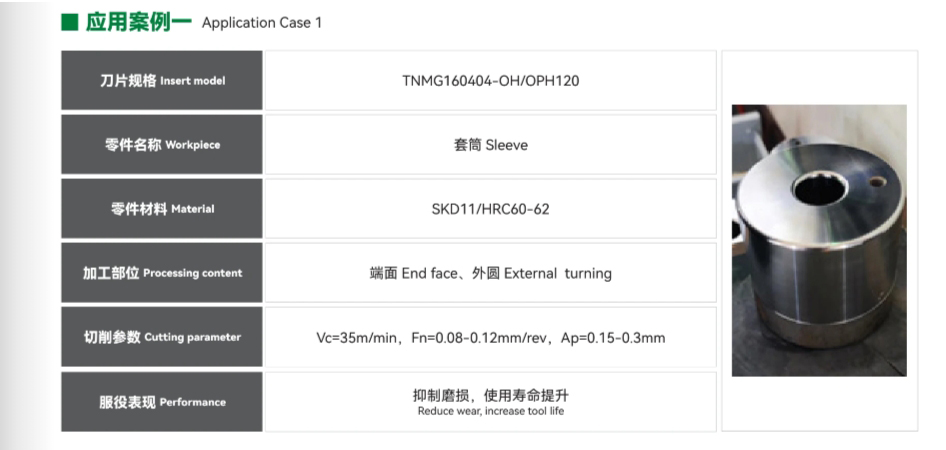

Mlandu wogwiritsa ntchito:

5.. Malangizo ndi Chidule

Kutengera kusanthula pamwambapa, zotsatirazi ziyenera kulingaliridwa mukamasankha magetsi a chitsulo chovuta:

Kugwirizana kwazinthu: Onetsetsani kuti kuvuta kwazinthu zakuthupi kumagwera pamtundu wa malo (E.g., OPH120 ndioyenera 45-60hrc).

Mtundu wa Makina: Kutsiriza kapena kumaliza? CD2025h ndiyabwino kwambiri kuti adzamalize mpaka kumaliza.

Ikani mawonekedwe: Sankhani mawonekedwe oyenera kutengera malo opangira (E.g., wnmg08 pakutembenuka kwakunja).

Kudula magawo:

Kudula Kuthamanga: Nthawi zambiri sankhani kuthamanga kwapang'onopang'ono kwa machitsulo osakhalitsa (30-80 m / min).

DZIWANI ZOTHANDIZA: Sankhani zakudya zazing'ono zomaliza (0.05-0.25 mm / rev).

Kudula mozama: Sankhani zozama zazing'ono kuti mutsirize (0.15-0.3 mm).

Kuchita bwino kwachuma: Ngakhale kuti ndalama zapamwamba zimatha kukhala ndi mtengo wapamwamba, moyo wokulitsa umatha kuchepetsa ndalama zambiri.

CD2025h mndandanda wankhani, ndi ukadaulo wawo wapamwamba, nyengo yawo yapamwamba kwambiri, yolimba kwambiri, komanso kukhazikika kwa chip, kumapereka njira yodalirika yothetsera zitsulo zolimba. Kuti musankhe zenizeni, kudula mayesero tikulimbikitsidwa kusintha magawo pazotsatira zapadera zothandizira kugwiritsa ntchito bwino pachuma.

Kudzera mwa kusankha kwasayansi ndikugwiritsa ntchito moyenera, kugwiritsa ntchito bwino ntchito ndi mtundu wa chitsulo cholimba kumatha kukhala bwino kwambiri, ndalama zopanga zopanga zimachepetsedwa, komanso phindu lalikulu lomwe limapangidwa pakupanga mabizinesi opanga.