- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Kaonekeswe

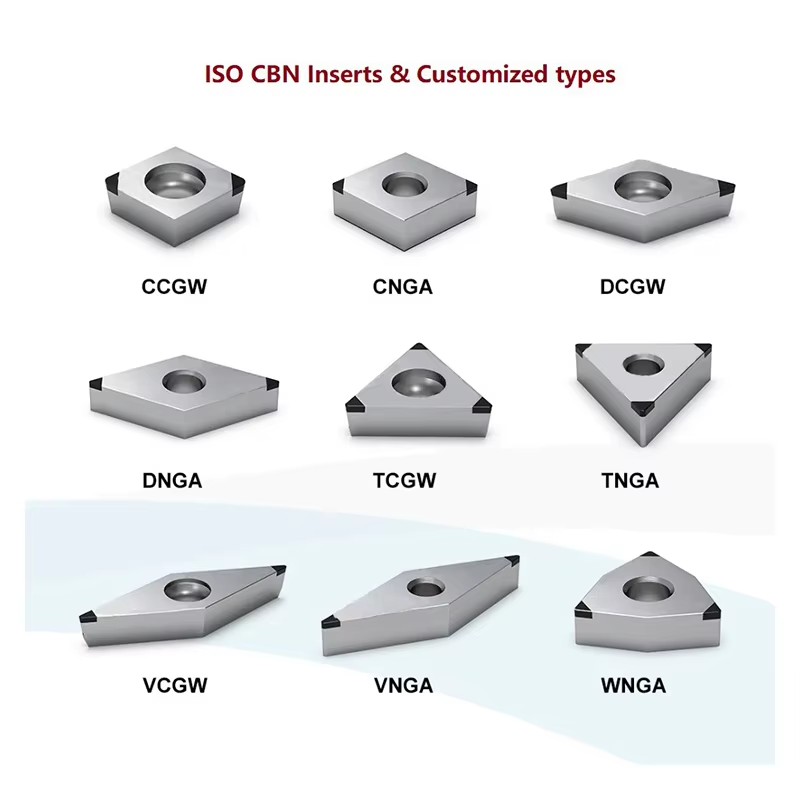

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

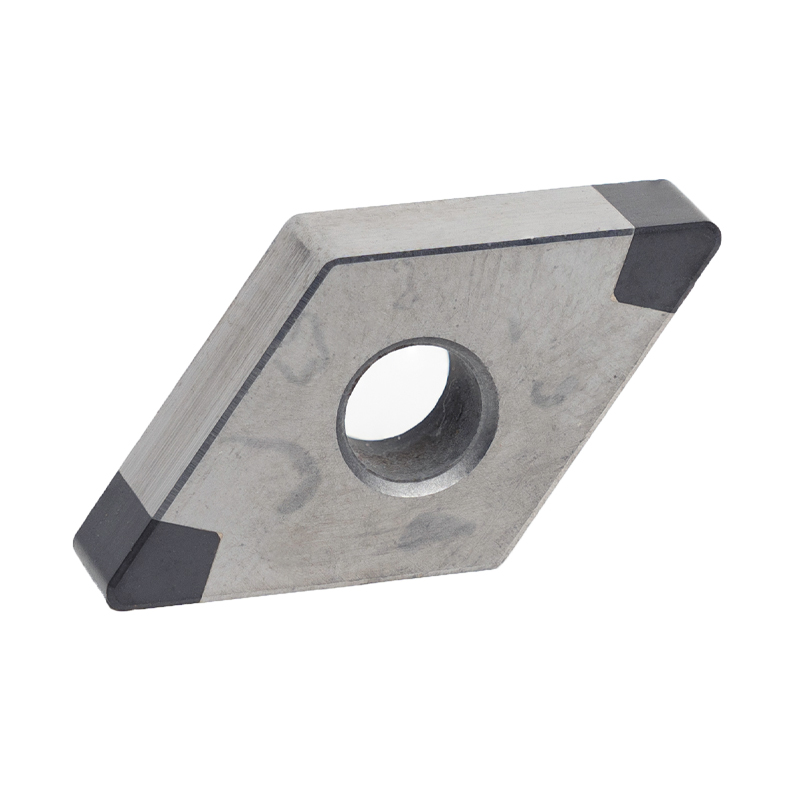

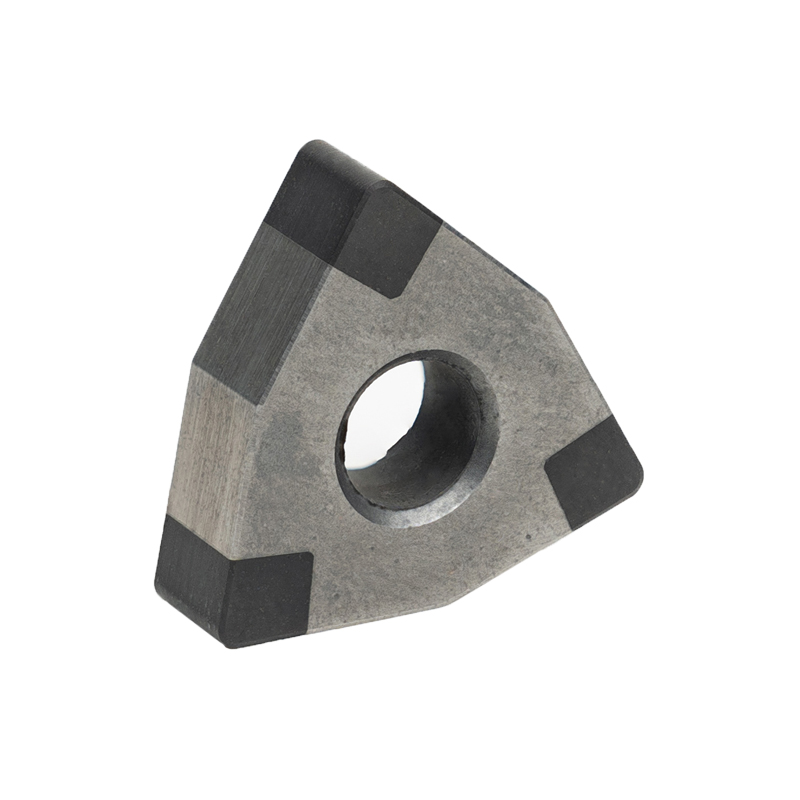

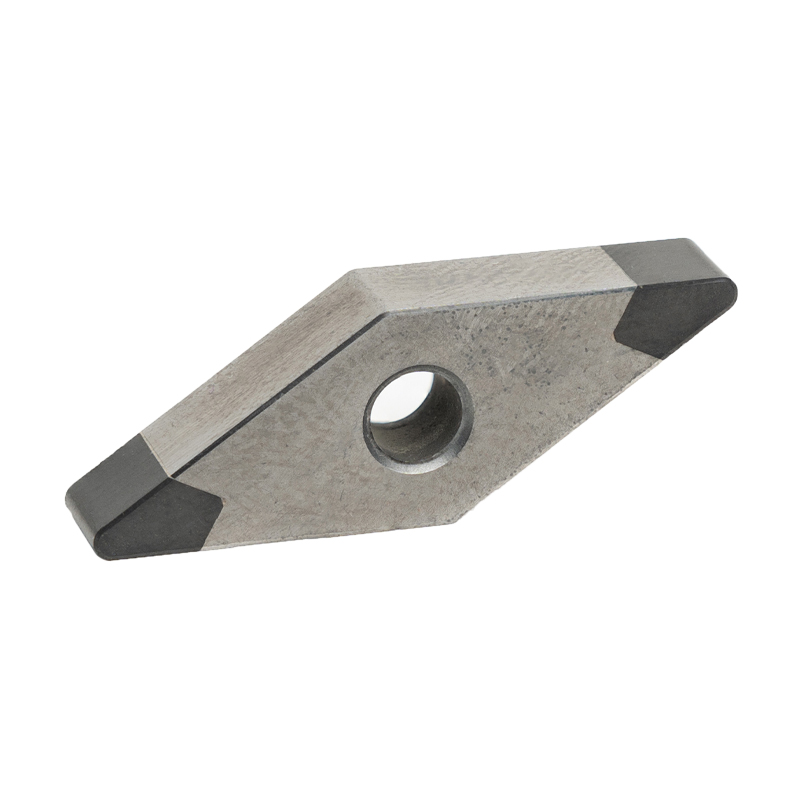

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

Welded cubic boron nitride blade

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

FAQ

1) Kodi ndingapeze liti mtengo wake?

Nthawi zambiri timatchula mawu pasanathe maola 24 titafunsidwa.Ngati mukufulumira kuti mupeze mtengo, chonde tiyimbireni kapena tiwuzeni mu imelo yanu kuti tiwone zomwe mukufuna patsogolo.

2) Ndingapeze bwanji chitsanzo kuti muwone ubwino wanu?

Pambuyo kutsimikizira mtengo, mungafunike zitsanzo kuti tione khalidwe lathu. Ngati mukungofunika chitsanzo chopanda kanthu kuti muwone kapangidwe kake ndi mtundu wa pepala, tidzakupatsani zitsanzo zaulere, bola mungakwanitse kunyamula katundu.

3) Kodi ndingayembekezere kutenga chitsanzo mpaka liti?

Mutatha kulipira chitsanzo ndi kutitumizira mafayilo otsimikiziridwa, zitsanzozo zidzakhala zokonzeka kutumizidwa m'masiku 3-7. Zitsanzo zidzatumizidwa kwa inu kudzera pa Express ndikufika pamasiku 3-7 ogwira ntchito. Mutha kugwiritsa ntchito akaunti yanuyanu kapena kutilipiriratu ngati mulibe akaunti.

4) Kodi ndondomeko yonseyi ikuchitika nthawi yayitali bwanji?

Mutatha kuyitanitsa, nthawi yogwira ntchito ndi pafupifupi masiku 20-25. Timafunika masiku 7 kukonza zinthu zonse kenako masiku 15 kupanga.

5) Nanga bwanji tsiku la mayendedwe ndi kutumiza?

Nthawi zambiri timagwiritsa ntchito kutumiza katunduyo.Ndi pafupi masiku 7-25.Zimadaliranso kuti coutry ndi doko muli chiyani.Zingakhale zazifupi ngati mukufuna kutumiza katundu ngati Asia. Ngati pali zadzidzidzi titha kutumiza katunduyo kudzera pa air Express, bola mungakwanitse kulipira ndalama zamagalimoto.

6) Kodi ndinu makampani ogulitsa kapena opanga?

Ndife akatswiri opanga. Sitingokhala ndi fakitale yathu ya zida, komanso tili ndi fakitale ya simenti ya carbide.

7) Kodi fakitale yanu ili kuti?

Tili mu mzinda wa Zhuzhou, Province la Hunan., tawuni ya tungsten carbide ku China.

8) Kodi ndingayembekezere kutenga chitsanzo mpaka liti?

Mutatha kulipira chitsanzo ndi kutitumizira mafayilo otsimikiziridwa, zitsanzozo zidzakhala zokonzeka kutumizidwa m'masiku 3-7. Zitsanzo zidzatumizidwa kwa inu kudzera pa Express ndikufika pamasiku 3-5 ogwira ntchito. Mutha kugwiritsa ntchito akaunti yanuyanu kapena kutilipiriratu ngati mulibe akaunti.

9) Nanga katundu wanu?

Tili ndi zinthu zambiri zomwe zilipo, mitundu yokhazikika komanso makulidwe ake onse ali mgulu.

10) Kodi kutumiza kwaulere kuli kotheka?

Sitimapereka ntchito yotumizira kwaulere. Titha kuchotsera ngati mutagula zinthu zambiri

Omasuka kulankhula nane:

Ayimee

Oyang'anira ogulitsa

Malingaliro a kampani Zhuzhou Chuangde Cemented Carbide Co., Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, District Tianyuan, Zhuzhou City.

Imelo: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688