- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Ibisobanuro

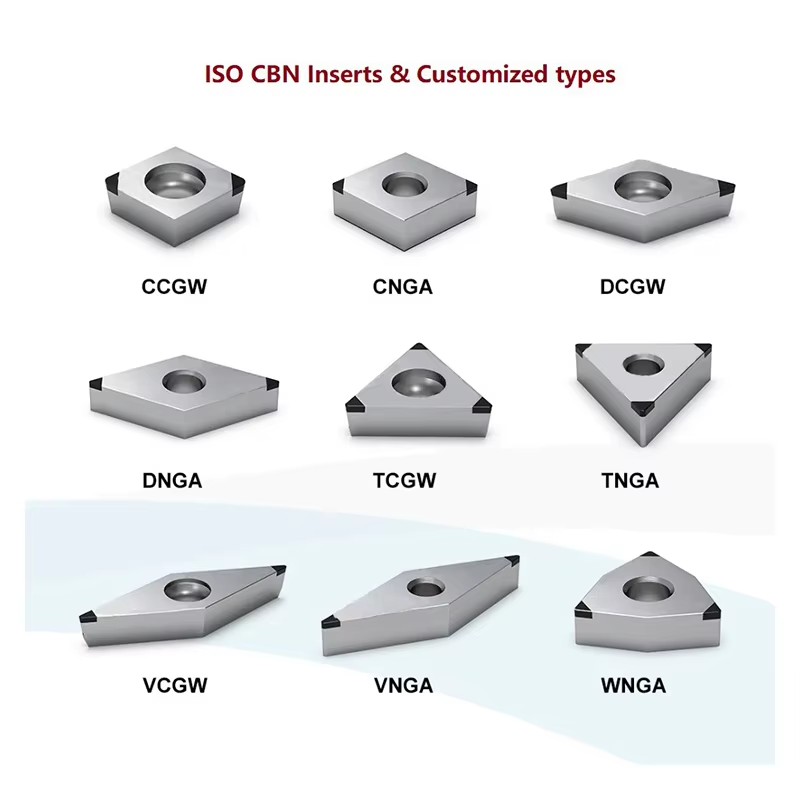

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

Welded cubic boron nitride blade

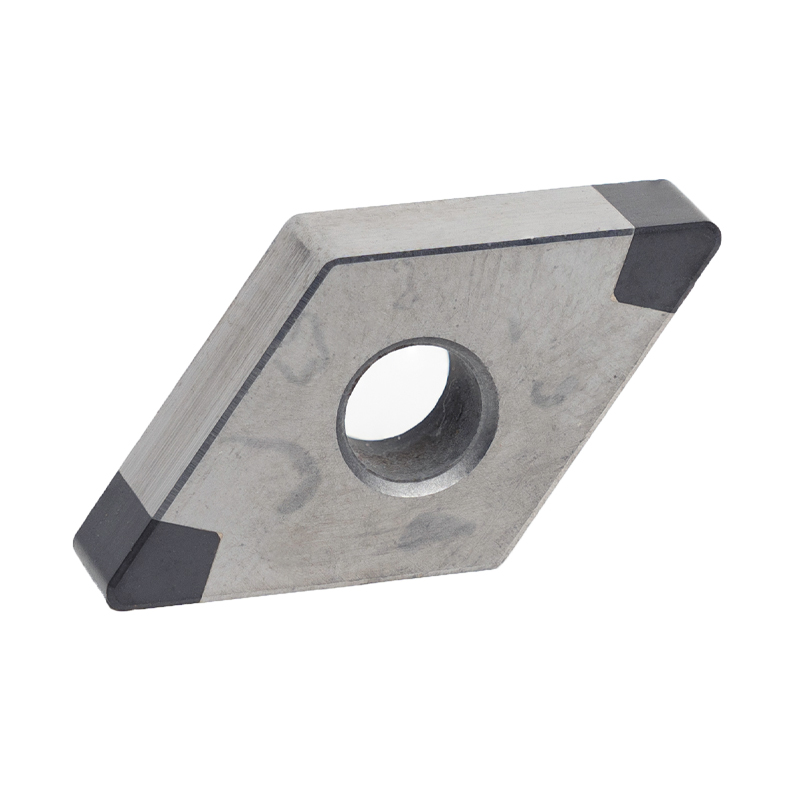

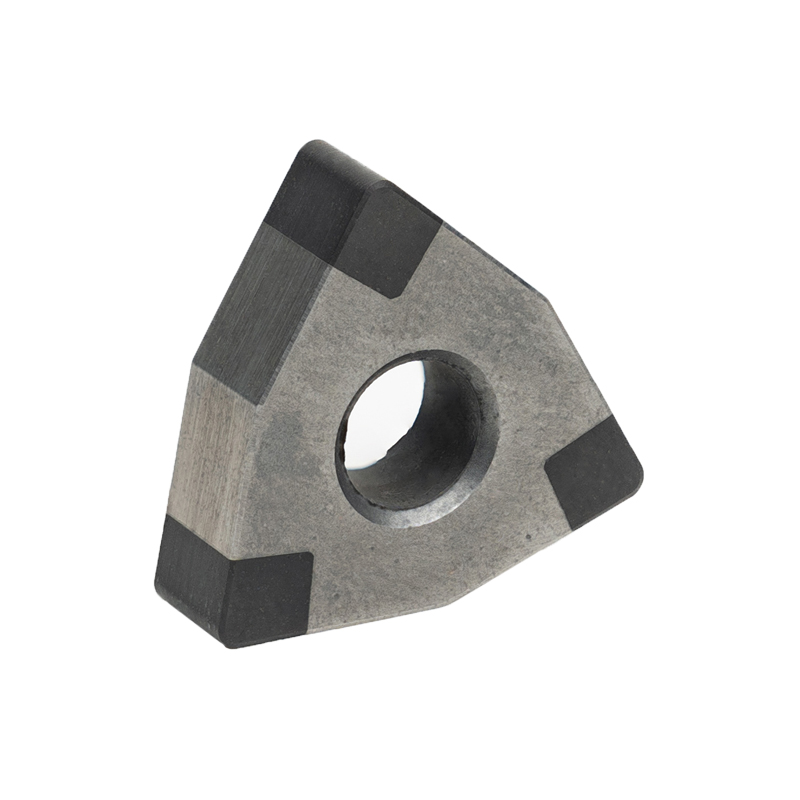

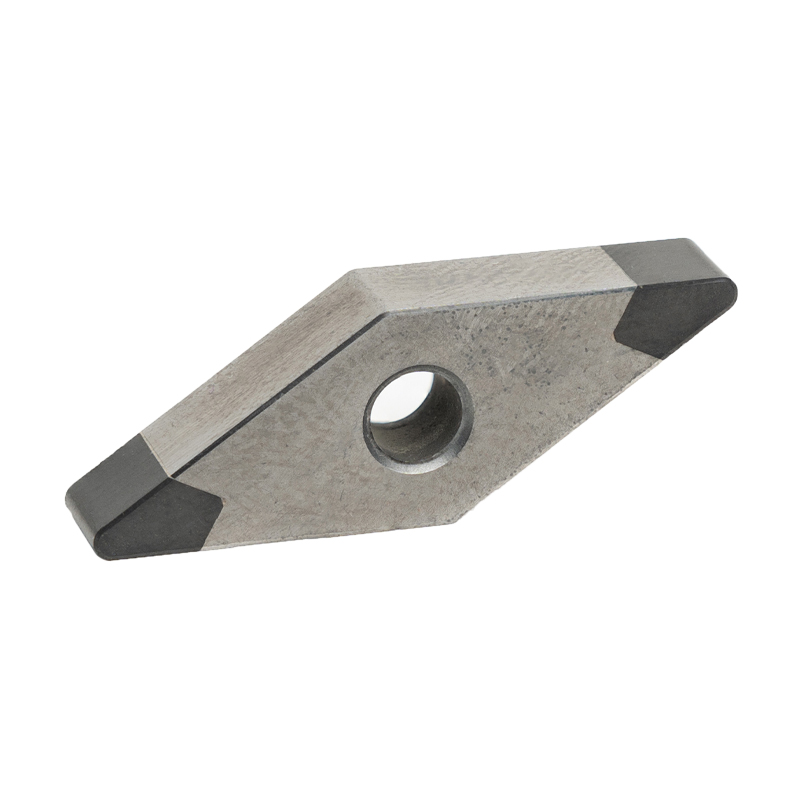

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

Ibibazo

1) Ni ryari nshobora kubona igiciro?

Mubisanzwe twavuze mumasaha 24 tumaze kubona anketi yawe.Niba wihutirwa cyane kubona igiciro, nyamuneka uduhamagare cyangwa utubwire muri imeri yawe kugirango turebe ikibazo cyawe cyambere.

2) Nigute nabona icyitegererezo cyo kugenzura ubuziranenge bwawe?

Nyuma yo kwemeza ibiciro, urashobora gusaba ingero zo kugenzura ubuziranenge bwacu. Niba ukeneye gusa icyitegererezo cyo kugenzura igishushanyo mbonera hamwe nimpapuro, tuzaguha icyitegererezo kubuntu, mugihe cyose uguze ibicuruzwa byihuta.

3) Nshobora gutegereza kugeza ryari kubona icyitegererezo?

Nyuma yo kwishyura icyitegererezo hanyuma ukatwoherereza dosiye zemejwe, ibyitegererezo bizaba byiteguye gutangwa muminsi 3-7. Ibyitegererezo bizoherezwa ukoresheje Express hanyuma bigere kumunsi wakazi 3-7. Urashobora gukoresha konte yawe yihariye cyangwa ukatwishura niba udafite konti.

4) Gahunda yose ikorwa kugeza ryari?

Nyuma yo gutumiza, igihe cyo gutunganya umusaruro ni iminsi 20-25. Dukeneye iminsi 7 yo gutegura ibintu byose hanyuma iminsi 15 yo gukora.

5) Bite ho itariki yo gutwara no gutanga?

Mubisanzwe dukoresha ibyoherejwe kugirango duhindure ibicuruzwa.Ni iminsi igera kuri 7-25. Biterwa kandi na coutry hamwe nicyambu urimo.Bishobora kuba bigufi mugihe ukeneye kohereza ibicuruzwa nka Aziya. Niba haribintu byihutirwa dushobora kohereza ibicuruzwa dukoresheje indege ya Express, mugihe cyose wishyuye amafaranga yumuhanda.

6) Urimo gucuruza sosiyete cyangwa manufaturer?

Turi abanyamwuga. Ntabwo dufite uruganda rwibikoresho gusa, ahubwo dufite uruganda rwa sima.

7) Uruganda rwawe ruherereye he?

Turi mu mujyi wa Zhuzhou, Intara ya Hunan., Tungsten carbide base of China

8) Nshobora gutegereza kugeza ryari kubona icyitegererezo?

Nyuma yo kwishyura icyitegererezo hanyuma ukatwoherereza dosiye zemejwe, ibyitegererezo bizaba byiteguye gutangwa muminsi 3-7. Ibyitegererezo bizoherezwa ukoresheje Express hanyuma bigere kumunsi wakazi 3-5. Urashobora gukoresha konte yawe yihariye cyangwa ukatwishura niba udafite konti.

9) Bite ho ububiko bwawe?

Dufite ibicuruzwa byinshi mububiko, ubwoko busanzwe nubunini byose biri mububiko.

10) Kohereza kubuntu birashoboka?

Ntabwo dutanga serivisi yo kohereza kubuntu. Turashobora kugira igiciro niba uguze ibicuruzwa byinshi

Wumve neza ko umpamagara:

Aimee

Umuyobozi ushinzwe kugurisha

Zhuzhou Chuangde Cemented Carbide Co. Ltd.

215, building 1, International Students Pioneer Park,

TaishanRoad, Akarere ka Tianyuan, Umujyi wa Zhuzhou.

Imeri: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp / wechat / Skype: 0086 13786352688