- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Opis

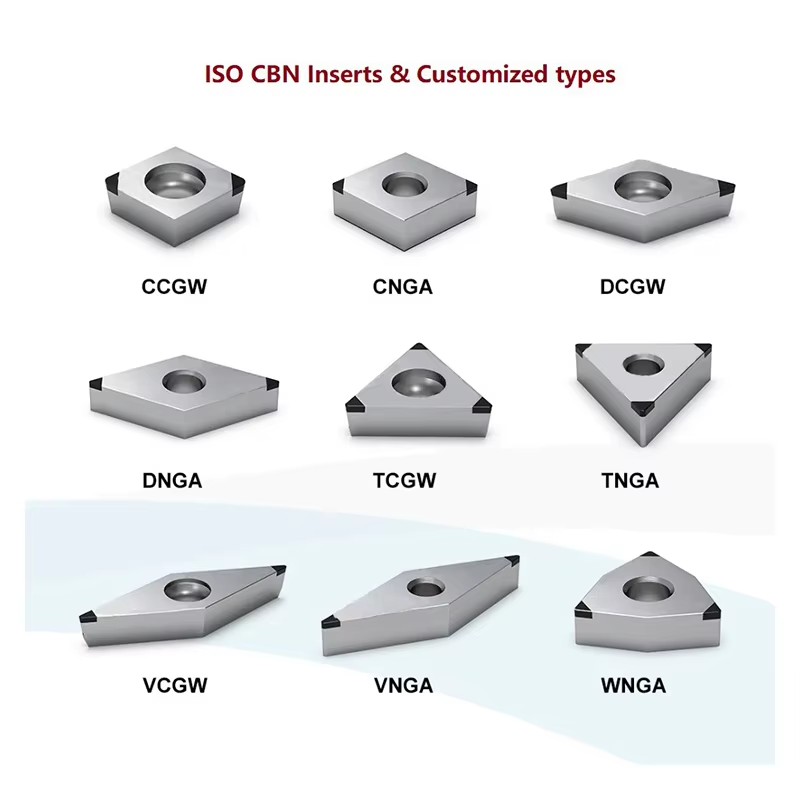

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

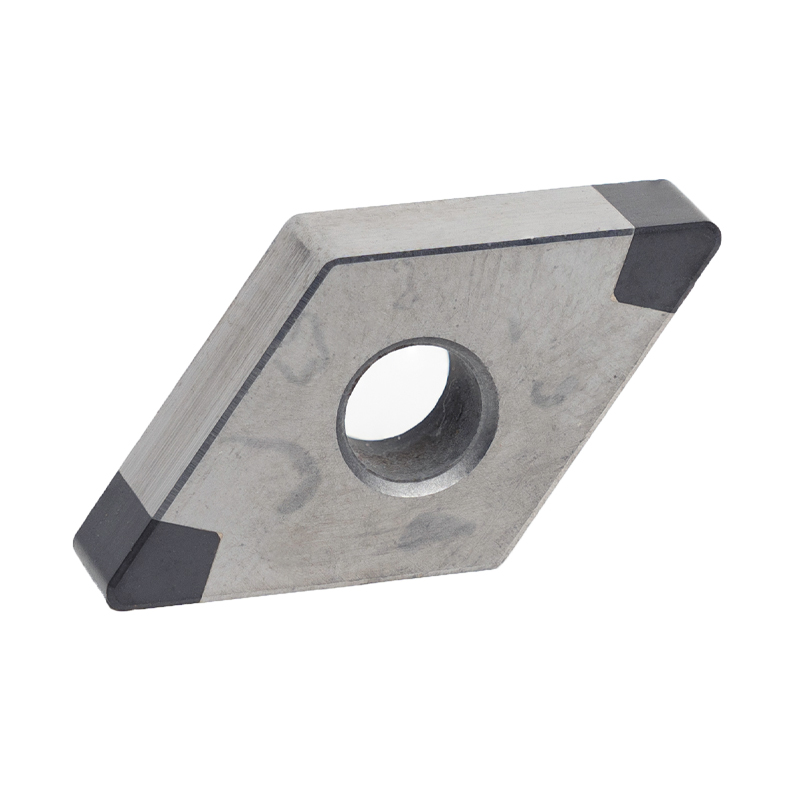

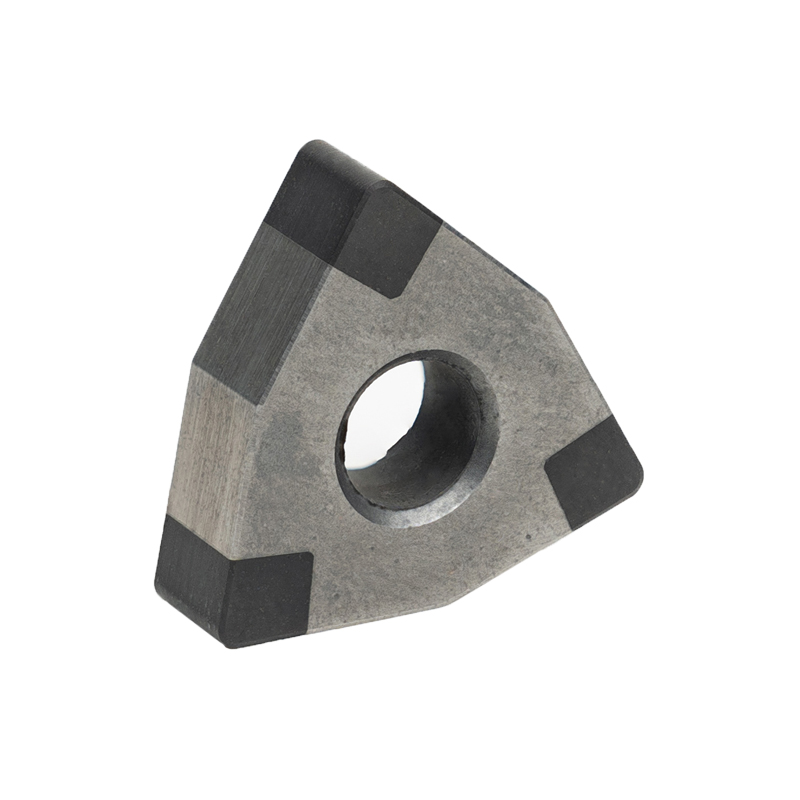

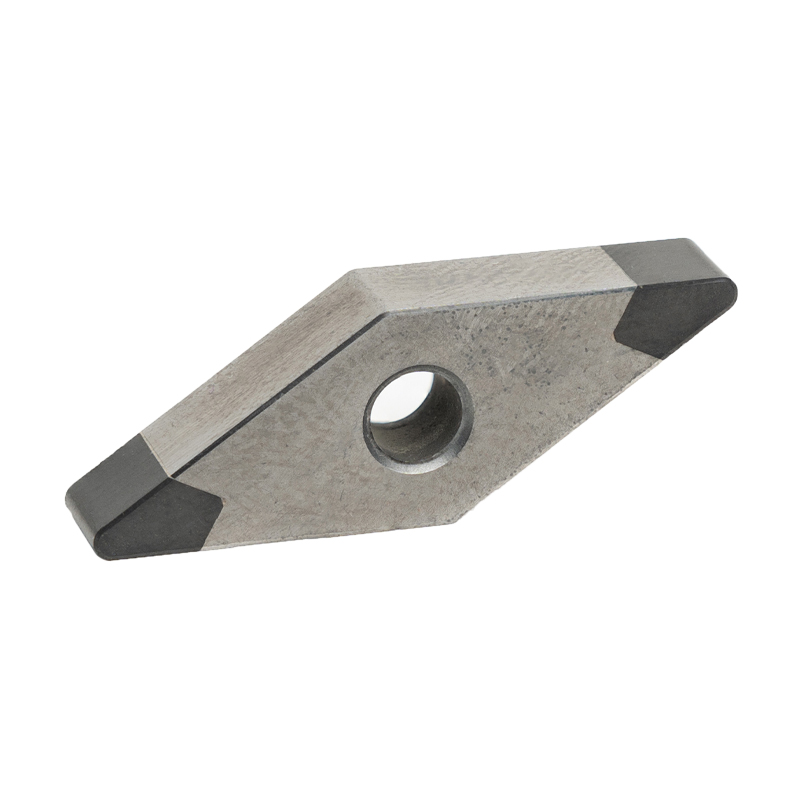

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

Welded cubic boron nitride blade

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

Pogosta vprašanja

1) Kdaj lahko dobim ceno?

Običajno ponudimo ponudbo v 24 urah po tem, ko prejmemo vaše povpraševanje. Če ste zelo nujni, da bi dobili ceno, nas pokličite ali nam sporočite v e-pošti, da bomo upoštevali vašo prednostno povpraševanje.

2) Kako lahko dobim vzorec za preverjanje vaše kakovosti?

Po potrditvi cene lahko zahtevate vzorce, da preverite našo kakovost. Če potrebujete samo prazen vzorec za preverjanje dizajna in kakovosti papirja, vam bomo brezplačno zagotovili vzorec, če si privoščite ekspresni tovor.

3) Kako dolgo lahko pričakujem, da bom dobil vzorec?

Ko plačate strošek vzorca in nam pošljete potrjene datoteke, bodo vzorci pripravljeni za dostavo v 3-7 dneh. Vzorci vam bodo poslani po hitri in prispeli v 3-7 delovnih dneh. Če nimate računa, lahko uporabite svoj ekspresni račun ali nam plačate vnaprej.

4) Kako dolgo traja celoten postopek?

Po oddaji naročila je rok izdelave približno 20-25 dni. Za pripravo vseh stvari potrebujemo 7 dni, nato pa 15 dni za izdelavo.

5) Kaj pa prevoz in datum dostave?

Običajno uporabljamo pošiljko za transport blaga. To je približno 7-25 dni. Prav tako je odvisno od tega, v kateri državi in pristanišču ste. Lahko bi bilo krajše, če morate poslati blago, kot je azijsko. V nujnih primerih lahko blago pošljemo po letalski hitri, če si privoščite prometne stroške.

6) Ali ste trgovsko podjetje ali proizvajalec?

Smo profesionalni proizvajalec. Nismo samo lastniki naše tovarne orodij, ampak imamo tudi tovarno cementnega karbida.

7) Kje se nahaja vaša tovarna?

Nahajamo se v mestu Zhuzhou, provinca Hunan., mesto na Kitajskem, ki temelji na volframovem karbidu

8) Kako dolgo lahko pričakujem, da bom dobil vzorec?

Ko plačate strošek vzorca in nam pošljete potrjene datoteke, bodo vzorci pripravljeni za dostavo v 3-7 dneh. Vzorci vam bodo poslani po hitri in prispeli v 3-5 delovnih dneh. Če nimate računa, lahko uporabite svoj ekspresni račun ali nam plačate vnaprej.

9) Kaj pa vaša zaloga?

Na zalogi imamo velike količine izdelkov, običajne vrste in velikosti so vse na zalogi.

10) Ali je mogoča brezplačna dostava?

Ne ponujamo storitve brezplačne dostave. Pri nakupu večje količine izdelkov imamo lahko popust

Kontaktirajte me:

Aimee

Vodja prodaje

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

Taishan Road, okrožje Tianyuan , mesto Zhuzhou.

Elektronski naslov: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688