- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Faʻamatalaga

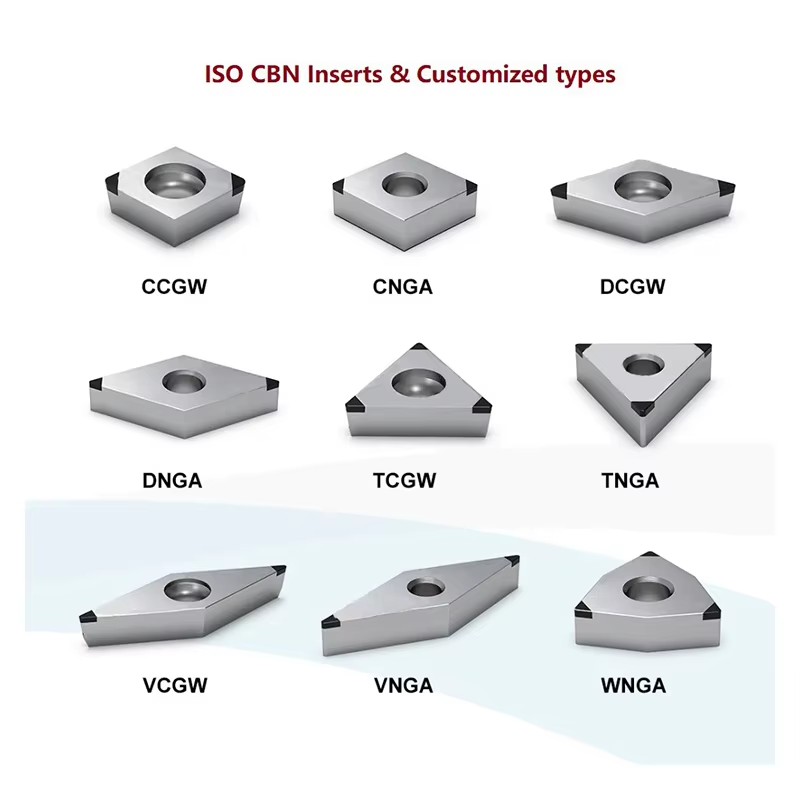

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

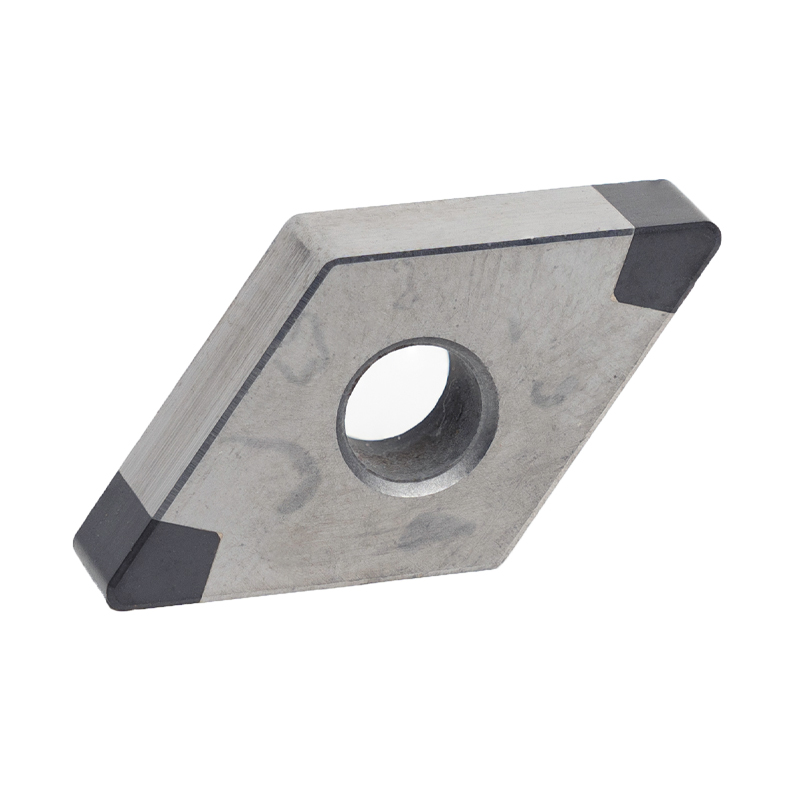

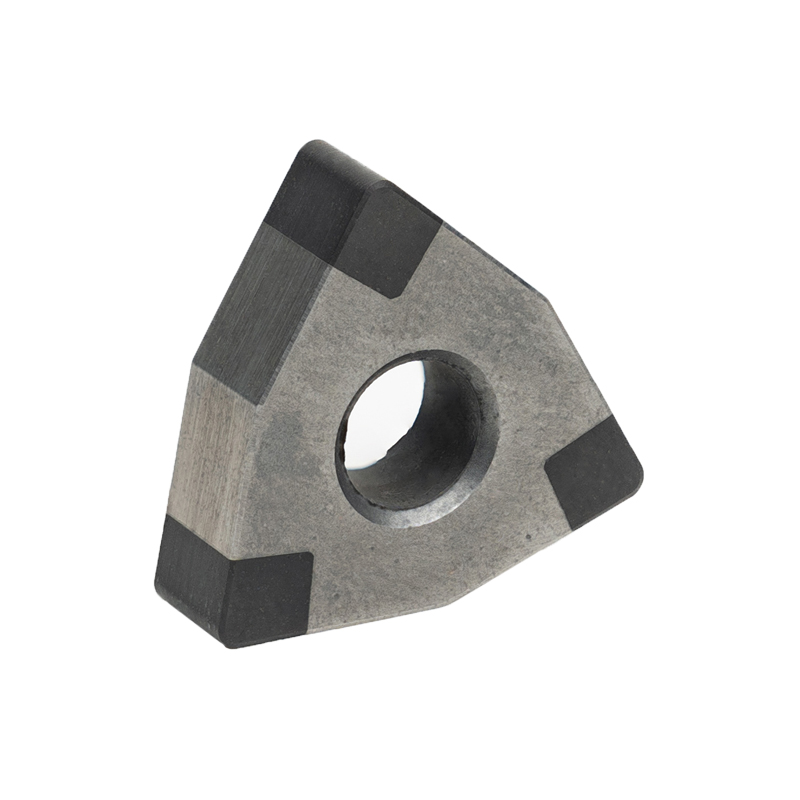

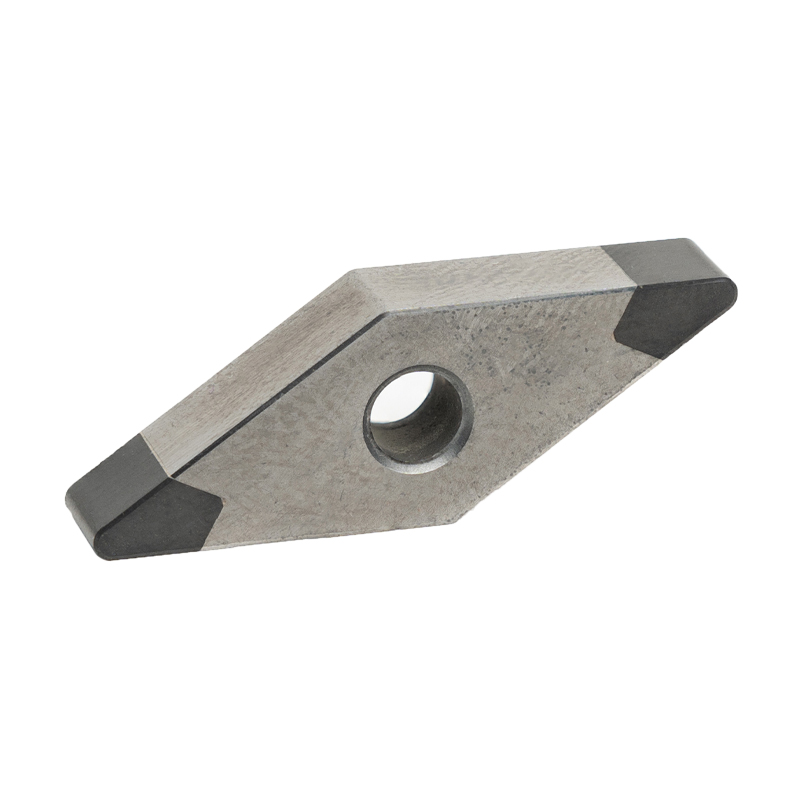

Welded cubic boron nitride blade

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

FAQ

1) O afea e mafai ai ona ou maua le tau?

E masani ona matou sii maia i totonu ole 24 itula talu ona maua lau suʻesuʻega.Afai e te matua faanatinati e maua le tau, faʻamolemole valaʻau mai pe taʻu mai ia i matou i lau imeli ina ia matou manatu i lau suʻesuʻega faʻamuamua.

2) E mafai faapefea ona ou maua se faʻataʻitaʻiga e siaki ai lou tulaga lelei?

A maeʻa faʻamaoniga tau, e mafai ona e manaʻomia mo faʻataʻitaʻiga e siaki ai lo matou lelei. Afai e te manaʻomia se faʻataʻitaʻiga avanoa e siaki ai le mamanu ma le tulaga lelei o pepa, matou te tuʻuina atu ia te oe faʻataʻitaʻiga e aunoa ma se totogi, pe afai e te gafatia le uta faʻaalia.

3) O le a le umi e mafai ona ou faʻamoemoe e maua ai le faʻataʻitaʻiga?

A maeʻa ona e totogiina le tau faʻataʻitaʻiga ma auina mai ia i matou faila faʻamaonia, o le a saunia faʻataʻitaʻiga mo le tuʻuina atu i le 3-7 aso. O faʻataʻitaʻiga o le a tuʻuina atu ia te oe e ala ile faʻaalia ma taunuu ile 3-7 aso faigaluega. E mafai ona e fa'aogaina lau oe fa'amatalaga fa'amatalaga pe totogi muamua matou pe a leai sau teugatupe.

4) O le a le umi e fa'atino ai le fa'agasologa atoa?

A maeʻa ona e tuʻuina se faʻatonuga, o le taimi e faʻatautaia ai le gaosiga e tusa ma le 20-25 aso. Matou te manaʻomia 7 aso e saunia ai mea uma ona 15 aso mo le gaosiga.

5) Ae faapefea le felauaiga ma le tuʻuina atu o aso?

E masani lava matou te faʻaaogaina uta e faʻafeiloaʻi ai oloa. E tusa ma le 7-25 aso. E faʻalagolago foi i le coutry ma le taulaga e te iai. Afai e iai ni fa'alavelave fa'afuase'i e mafai ona matou lafo atu oloa e ala i le ea express, pe afai e te gafatia le tau o felauaiga.

6) O oe kamupani fefaʻatauaʻiga poʻo le faʻatau?

O matou o le gaosiga faʻapolofesa. E le gata ina matou umia a matou fale gaosi mea faigaluega, ae o loʻo iai foʻi fale gaosi carbide sima.

7) O fea o iai lau falegaosimea?

O loʻo matou i totonu o le taulaga o Zhuzhou, Hunan Province., Tungsten carbide base taulaga o Saina

8) O le a le umi e mafai ona ou faʻamoemoe e maua ai le faʻataʻitaʻiga?

A maeʻa ona e totogiina le tau faʻataʻitaʻiga ma auina mai ia i matou faila faʻamaonia, o le a saunia faʻataʻitaʻiga mo le tuʻuina atu i le 3-7 aso. O faʻataʻitaʻiga o le a tuʻuina atu ia te oe e ala ile faʻaalia ma taunuu ile 3-5 aso faigaluega. E mafai ona e fa'aogaina lau oe fa'amatalaga fa'amatalaga pe totogi muamua matou pe a leai sau teugatupe.

9) Faʻafefea lau faʻasoa?

E tele a matou oloa i totonu o faʻatau, ituaiga masani ma lapopoa o loʻo i totonu uma.

10) E mafai ona lafo fua?

Matou te le ofo fua le felauaiga. E mafai ona matou maua se fa'aitiitiga pe afai e te fa'atau se oloa tele

Lagona le saoloto e fa'afeso'ota'i a'u:

Aimee

Pule fa'atau

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Imeli: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688