Sida loo xusho galka CNC ee mashiinka bir adag

Goobta farsamada farsamada, ka baaraandegida qalabka birta adag (sida birta adag iyo bir-adag) ayaa had iyo jeer ahaa tartan farsamo. Qalabkan ayaa muujinaya adkeyn iyo xoog sare, oo ku dhejinaya baahiyo ba'an oo ku saabsan goynta aaladaha goynta. Qodobkaani wuxuu u isticmaali doonaa CD Carbide-ka CD-ga ee taxanaha CD2025h ee taxanaha ah si loo bixiyo hage tilmaamaha xulashada aaladaha shaashadda adag, oo daboolaya tikniyoolajiyadda khaaska ah, tikniyoolajiyada shayga, iyo daraasadaha dhabta ah ee barashada.

1. Gali aaladda: isku darka kaamilka ah ee sunta waxqabadka sare iyo daboolka horumarsan

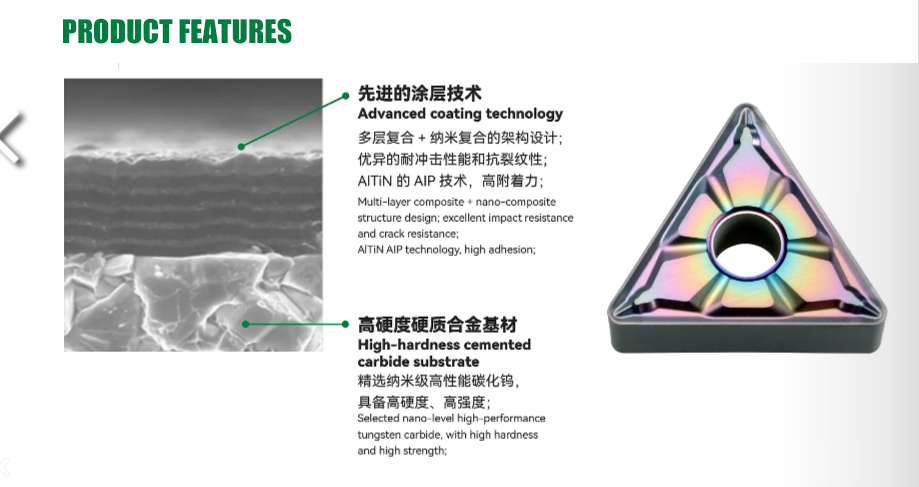

Tartanka aasaasiga ah ee gelitaanka CD2025h ayaa marka hore ku been abuurtaa tikniyoolajiyadooda maaddada:

Subbide-ka adag ee xasaasiga ah ee loo yaqaan 'Carbide' oo adag: laga sameeyay waxqabadka Heerarka Sare ee Heerarka Tungsten Carbsten Carbide, waxay isku daraysaa si adag oo heer sare ah iyo xoog sare, oo siinta aasaaska adag ee mashiinka adag.

Teknolojiyadda PVD ee Sare:

Xeerka lakabka badan + Nano-composite qaabeynta qaab dhismeedka

Caabbinta ugu fiican ee caabbinta iyo caabbinta dillaaca

Waxay u isticmaashaa tik tik tikniyoolajiyadda Aitin ee loogu talagalay adhesion adag

Isku-darka sheyga ayaa ka dhigaya oph120 si gaar ah u hagida mashiinnada adag ee adag sida birta aaladda Skd11 ee Skd11 ee 45-60hRC, sida lagu xusay daraasadda kiiska.

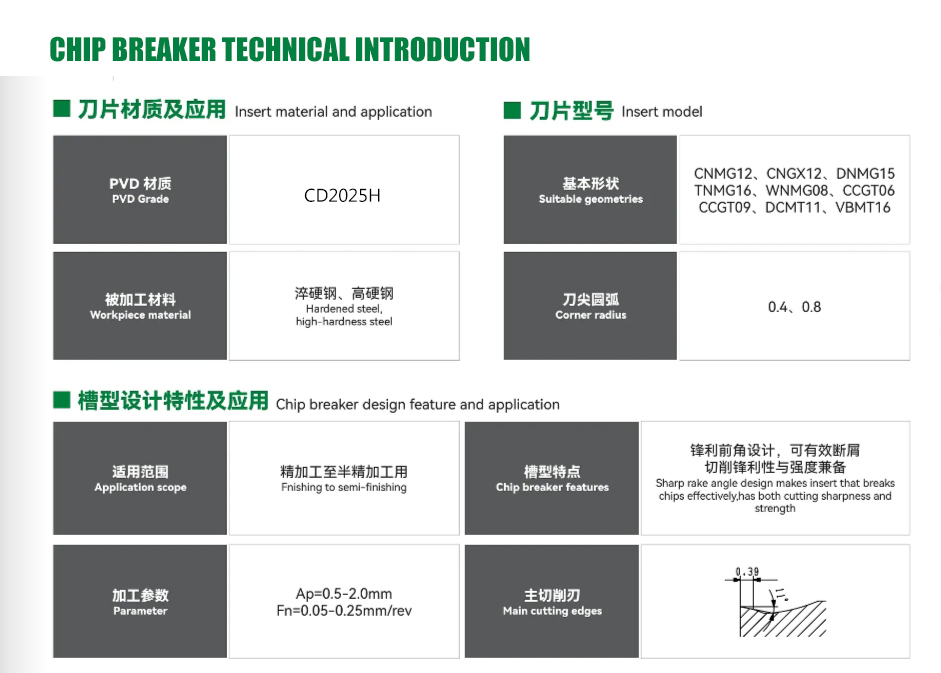

2.Chip tikniyoolajiyadda jebinta: Waxqabadka goynta ee injineerka

Tiknoolajiyadda chip-ka chip chap ch chip wuxuu siiyaa galinta CD2025h ee leh waxqabadka goynta qaddarka:

![]()

3. Codsi Fasalka: Saxeex sax ah baahiyaha farsamada

Sida laga soo xigtay heerarka ISO, astaamaha dalabka ee CD2025h waa sida soo socota:

Tilmaamaha ugu muhiimsan:

Adag oo adag oo caabbinta xidho

Ku habboon qalabka adag ee adag ilaa 45-60hrc

Xayeysiinta Xawaaraha Xawaaraha (30-80 M / MIN), oo lagu habeeyo iyadoo lagu saleynayo xaaladaha gaarka ah

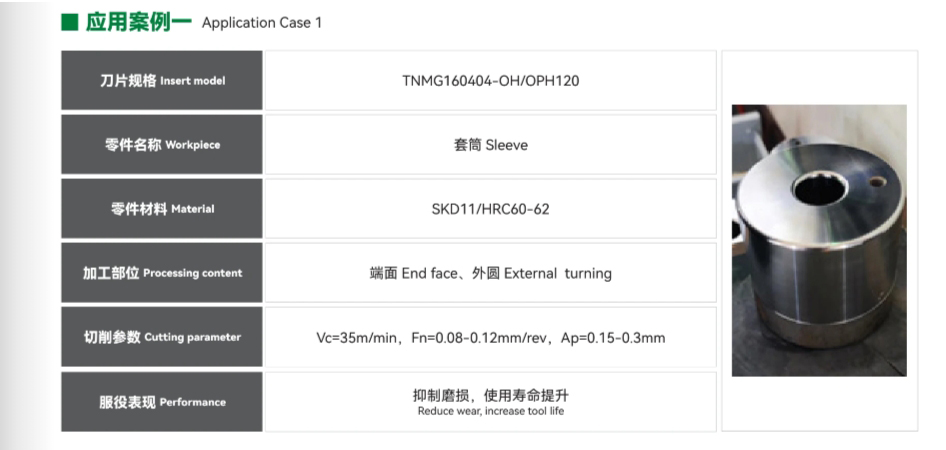

4. Kiiska arjiga ee Real-World-World: ansixinta waxqabadka badeecada

Kiis codsi oo caadi ah:

5. Xulashada talooyinka iyo Soo Koobid

Iyada oo ku saleysan falanqaynta kor ku xusan, qodobbada soosocda waa in laga fiirsadaa marka la dooranayo galinta galka mashiinka bir adag:

Isku-darka maaddada

Nooca farsamada: Dhameystirka ama ku dhameysiga? CD2025h waxay si gaar ah ugu habboon tahay dhammaystirka dhammaadka badbaadada.

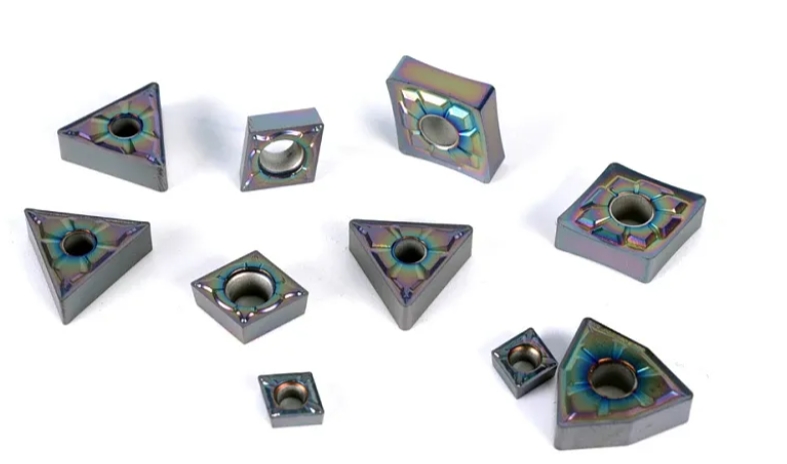

Gali Qaabka: Dooro qaabka ku habboon ee ku saleysan goobta mashiinka (E.G., WNMG08 ee daminta dibedda).

Qiyaasta goynta:

Xawaaraha Jardiga: Guud ahaan xulo xawaaraha hoose ee mashiinka bir adag (30-80 m / min).

Heerka Feed: Dooro quudinta yar ee ku saabsan dhammaadka (0.-0.25 mm / rev).

Qoto dheer goynta: Xulo qoto dheer oo yar oo ku saabsan dhammaadka (0.15-0.3 mm).

Waxqabadka dhaqaalaha: In kasta oo la galiyo waxqabadka sare laga yaabo inuu yeesho kharashka cutubka sare, kordhinta nooca nolosha ayaa yareyn kara kharashaadka qayb ka ah.

CD2025h waxay galeen taxane ah, oo leh tikniyoolajiyaddooda sare ee sare, substrate-ka sare, iyo qaabeynta chip-ka, waxay siisaa xalka lagu kalsoonaan karo ee mashiinka ugu adag. Wixii xulasho dhab ah, goynta maxkamadaynta ayaa lagula talinayaa in lagu hagaajiyo cabirrada ku saleysan natiijooyinka farsamada gaarka ah ee hufnaanta dhaqaale ee ugu habboon.

Iyada oo loo marayo xulashada sayniska iyo adeegsiga habboon, hufnaanta hufnaanta iyo tayada loogu talagalay birta adag ayaa si weyn loo wanaajin karaa, kharashyada waxsoosaarkana waa la dhimay, oo qiimo weyn loo sameeyay wax soo saarka ganacsiga.