- Material:100% virgin tungsten carbide

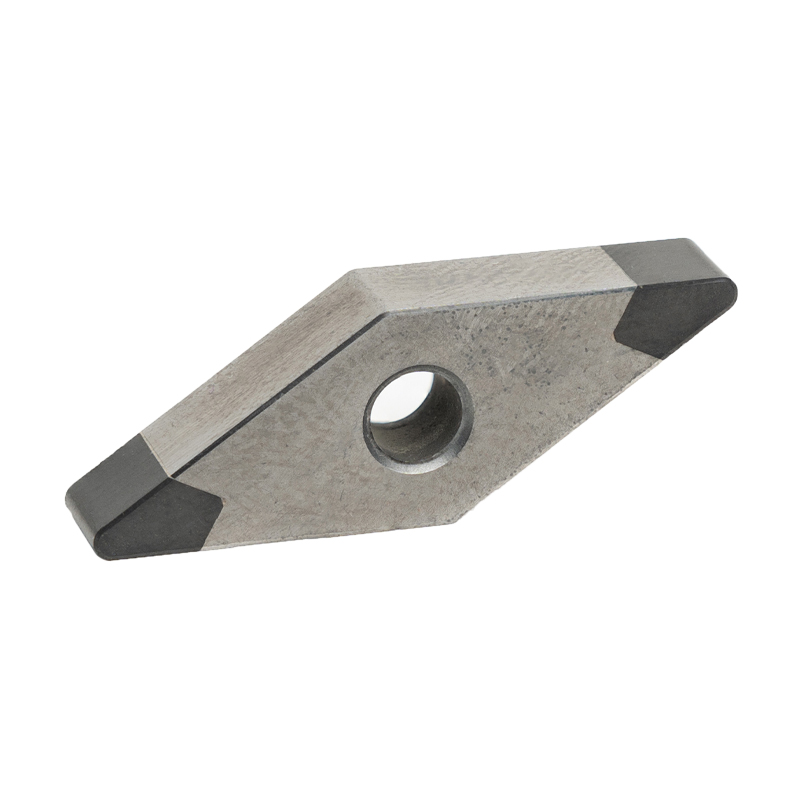

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Tlhaloso

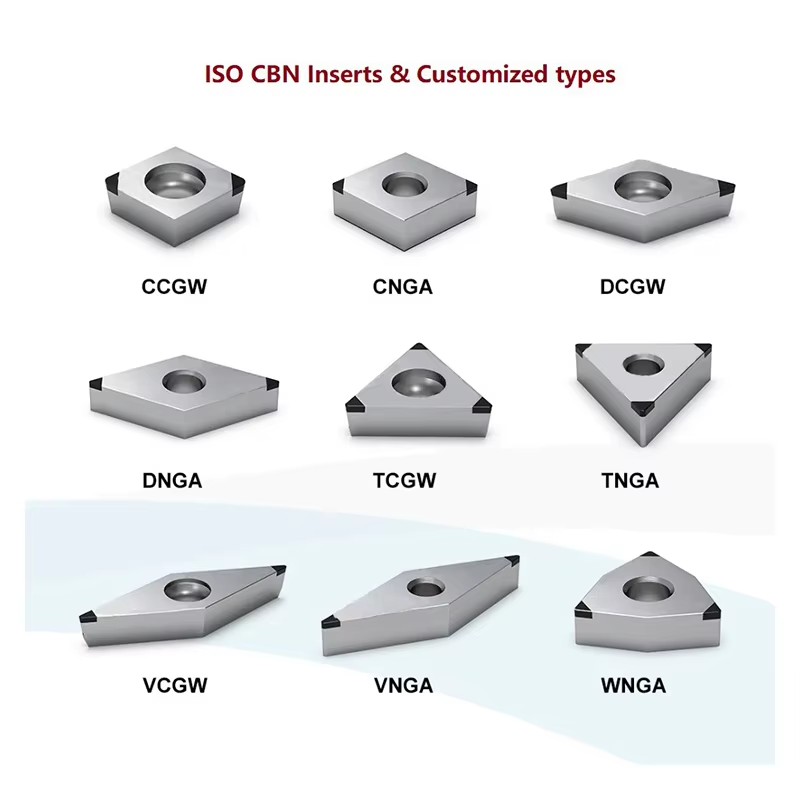

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

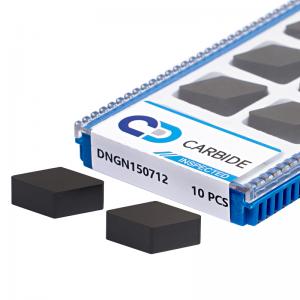

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

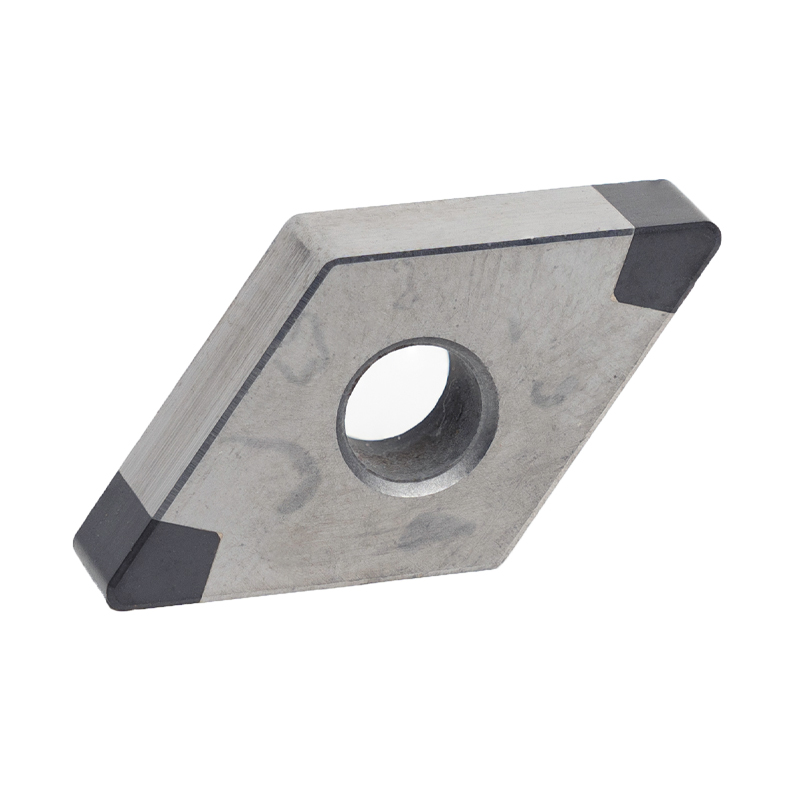

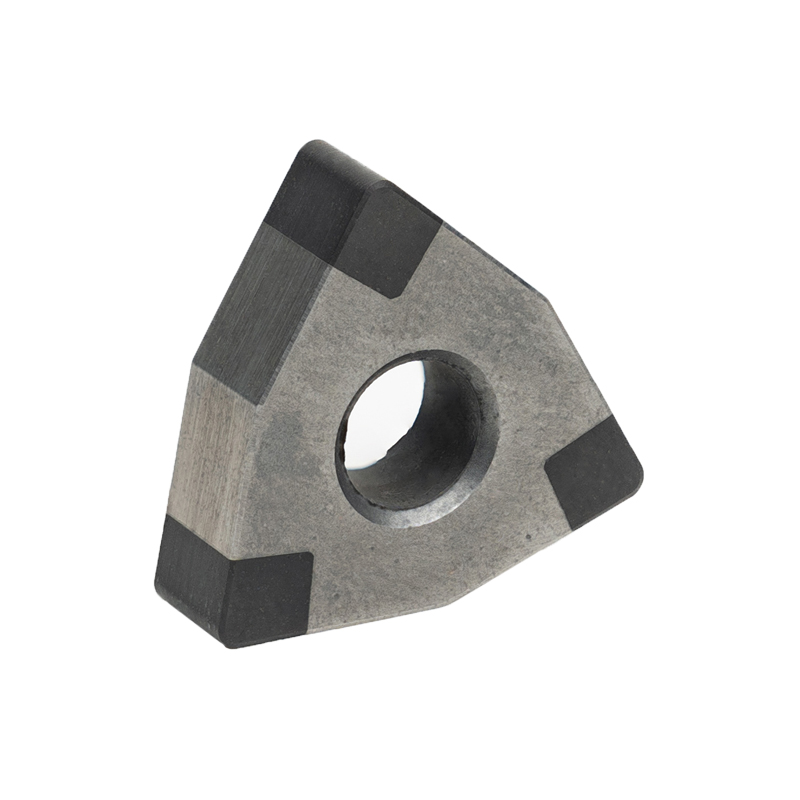

Welded cubic boron nitride blade

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

LBH

1) Nka fumana theko neng?

Hangata re qotsa ka hare ho lihora tse 24 ka mor'a hore re fumane potso ea hau.

2) Nka fumana mohlala joang ho hlahloba boleng ba hau?

Kamora netefatso ea theko, o ka hloka hore lisampole li hlahlobe boleng ba rona. Haeba u hloka feela sampole e se nang letho ho lekola moralo le boleng ba pampiri, re tla u fa sampole mahala, ha feela u khona ho reka thepa e potlakileng.

3) Nka lebella ho fumana sampole nako e kae?

Ka mor'a hore u lefelle tefo ea mohlala 'me u re romelle lifaele tse tiisitsoeng, mehlala e tla be e loketse ho tsamaisoa ka matsatsi a 3-7. Mehlala e tla romelloa ho uena ka tsela ea Express 'me e fihle ka mor'a matsatsi a 3-7 a mosebetsi. U ka sebelisa ak'haonte ea hau ea Express kapa ua re lefa esale pele haeba u sena ak'haonte.

4) Tsamaiso eohle e sebetsa nako e kae?

Ka mor'a hore u behe taelo, nako ea ho sebetsana le tlhahiso e ka ba matsatsi a 20-25. Re hloka matsatsi a 7 ho lokisa lintho tsohle ebe matsatsi a 15 bakeng sa tlhahiso.

5) Ho thoe'ng ka letsatsi la lipalangoang le la thomello?

Ka tloaelo re sebelisa thomello ho transprot thepa.E ka ba matsatsi a 7-25. E boetse e itšetlehile ka hore na u coutry le port eo u leng teng.E ka ba khutšoanyane haeba u hloka ho romela thepa e kang ea Asia. Haeba ho na le maemo a tšohanyetso re ka romella thepa ka air Express, ha feela o khona ho lefella litšenyehelo tsa sephethephethe.

6) Na u khoebo ea k'hamphani kapa moetsi?

Re moetsi oa litsebi. Ha re na feme ea lisebelisoa tsa rona feela, empa hape re na le feme ea carbide e samenteng.

7) Feme ea hau e hokae?

Re fumaneha toropong ea Zhuzhou, Profinseng ea Hunan., Tungsten carbide base town of China.

8) Nka lebella ho fumana sampole nako e kae?

Ka mor'a hore u lefelle tefo ea mohlala 'me u re romelle lifaele tse tiisitsoeng, mehlala e tla be e loketse ho tsamaisoa ka matsatsi a 3-7. Mehlala e tla romelloa ho uena ka tsela ea Express 'me e fihle ka mor'a matsatsi a 3-5 a mosebetsi. U ka sebelisa ak'haonte ea hau ea Express kapa ua re lefa esale pele haeba u sena ak'haonte.

9) Ho thoe'ng ka stock ea hau?

Re na le lihlahisoa tse ngata setokong, mefuta e tloaelehileng le boholo bo teng kaofela.

10) Na ho romelloa mahala hoa khoneha?

Ha re fane ka litšebeletso tsa mahala tsa thomello. Re ka ba le theolelo haeba u reka lihlahisoa tse ngata haholo

Ikutloe u lokolohile ho ikopanya le 'na:

Aimee

Mookameli oa thekiso

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Setereke sa Tianyuan, Zhuzhou City.

Lengolo-tsoibila: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688