- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

Tavsif

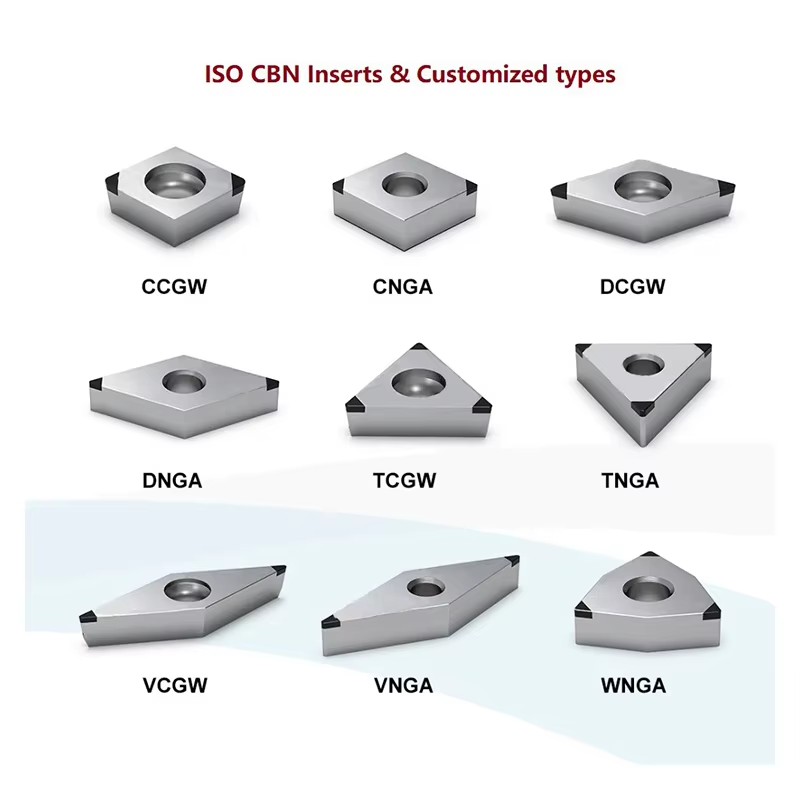

DNGA CNGA SNGA TNGA VNGA WNGA CNC CBN Inserts for Superhard Materials

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | DNGA CNGA SNGA TNGA VNGA WNGA |

Workpiece | High hardness steel |

Place of origin | Zhuzhou,Hunan,China |

MOQ Quantity | 10pcs |

Introduction to CBN inserts

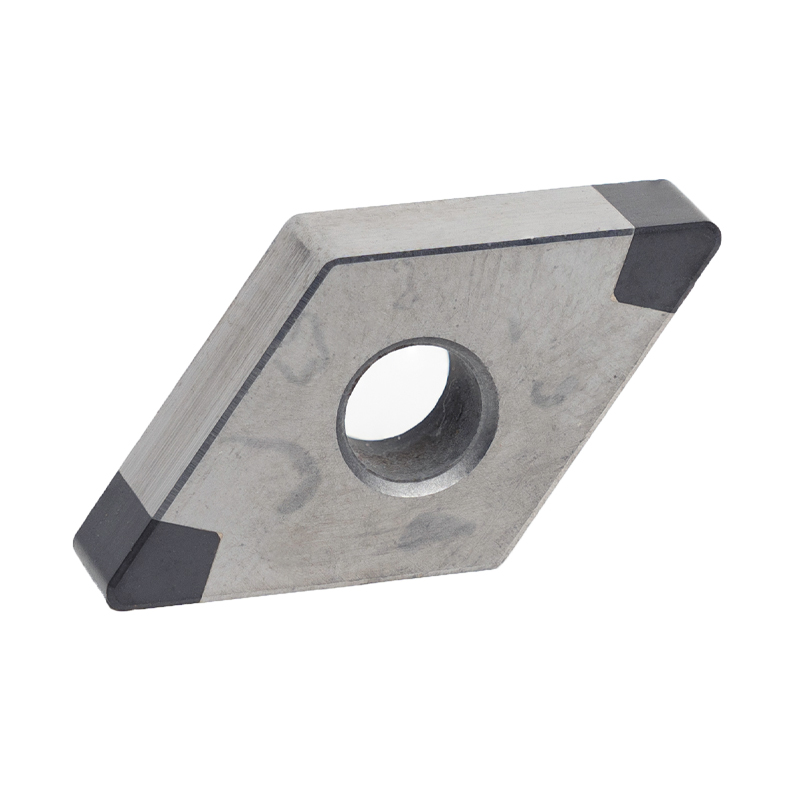

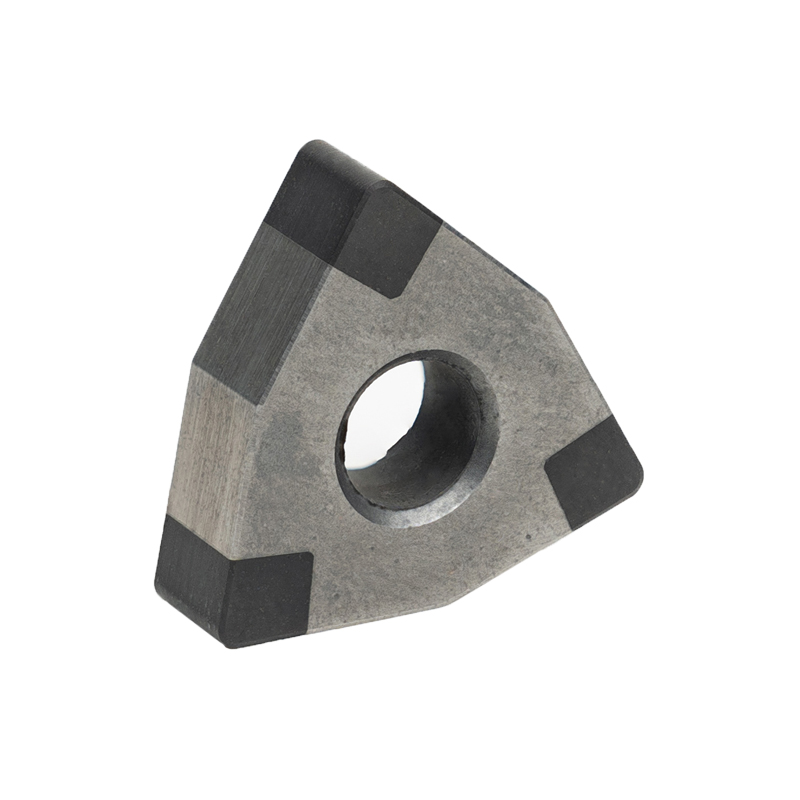

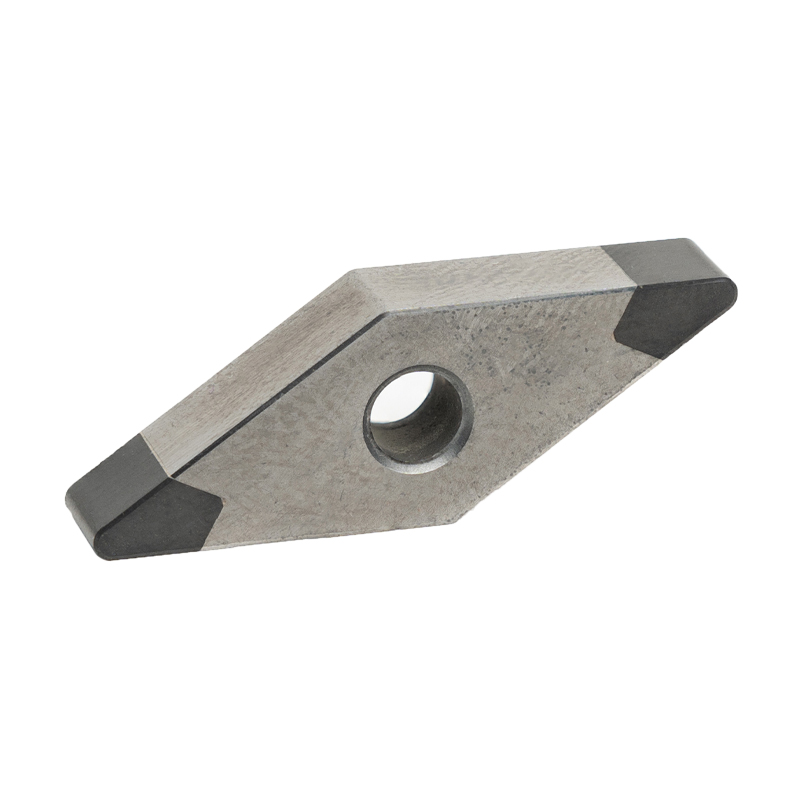

Welded cubic boron nitride blade

The tip is made of cubic boron nitride material, and the intermediate matrix is made of cemented carbide material. The CBN tip provides high hardness, high wear resistance and good thermal stability for cutting processing; the cemented carbide matrix has high strength and toughness, can withstand cutting force and impact, and provides reliable support for the CBN tip. There is a center hole for positioning, which can replace the coated blade. Common models include CNGA, SNGA, VNGA, etc.

Features of tungsten carbide CBN insert

Performance characteristics

1.High hardness and wear resistance: The hardness is second only to diamond, up to 3000-5000HV, suitable for processing high-hardness ferrous metal materials, such as hardened steel, mold steel, etc.

2.Good thermal stability: The heat resistance can reach 1400-1500℃, which is twice as high as the heat resistance of diamond, and can be used for high-speed turning.

3.Good chemical stability: It will not react chemically with iron materials at 1200-1300℃, and there will be no sharp wear during high-temperature cutting.

4.Good thermal conductivity: Much higher than high-speed steel and cemented carbide, which is conducive to reducing the temperature of the cutting area and reducing diffusion wear.

Low friction coefficient: The cutting force generated during cutting is small, which can effectively improve the surface quality.

The application areas of CBN insert

Automobile manufacturing: commonly used for processing engine parts and transmission system parts, such as high-speed hard turning of hardened steel gears, bearings, and crankshafts, which can replace grinding.

Aerospace: used to process difficult-to-process materials such as titanium alloys and nickel-based superalloys, such as high-temperature alloy material processing of turbine engine blades.

Mold manufacturing: can achieve efficient processing of hard mold steel (HRC 45 or above), improve processing accuracy and surface finish.

Heavy machinery manufacturing: used for processing high-strength steel parts required in large equipment, such as rough and fine processing of chilled cast iron rolls and high-chromium cast iron.

Our product show

TSS

1) Narxni qachon olsam bo'ladi?

Biz odatda sizning so'rovingizni olganimizdan keyin 24 soat ichida taklif qilamiz. Agar siz narxni olish uchun juda shoshilinch bo'lsangiz, iltimos, bizga qo'ng'iroq qiling yoki elektron pochta orqali xabar bering, shunda biz sizning so'rovingiz ustuvorligini hisobga olamiz.

2) Sizning sifatingizni tekshirish uchun qanday namuna olsam bo'ladi?

Narxni tasdiqlaganingizdan so'ng, sifatimizni tekshirish uchun namunalarni talab qilishingiz mumkin. Agar sizga dizayn va qog'oz sifatini tekshirish uchun shunchaki bo'sh namuna kerak bo'lsa, biz sizga ekspress yukni sotib olishingiz sharti bilan bepul namunani taqdim etamiz.

3) Namuna olishni qancha vaqt kutishim mumkin?

Namuna to'lovini to'laganingizdan va bizga tasdiqlangan fayllarni yuborganingizdan so'ng, namunalar 3-7 kun ichida yetkazib berishga tayyor bo'ladi. Namunalar sizga ekspress orqali yuboriladi va 3-7 ish kunida keladi. Siz o'zingizning ekspress hisobingizdan foydalanishingiz yoki hisobingiz bo'lmasa, bizga oldindan to'lashingiz mumkin.

4) Barcha protsedura qancha vaqt davomida ishlab chiqiladi?

Buyurtma berganingizdan so'ng, ishlab chiqarishni qayta ishlash muddati taxminan 20-25 kun. Hamma narsani tayyorlash uchun bizga 7 kun, keyin ishlab chiqarish uchun 15 kun kerak bo'ladi.

5) Tashish va etkazib berish sanasi haqida nima deyish mumkin?

Odatda biz yuklarni tashish uchun jo'natishdan foydalanamiz. Bu taxminan 7-25 kunni tashkil qiladi. Bu sizning qaysi koutri va portingizga ham bog'liq. Agar siz Osiyo kabi tovarlarni jo'natishingiz kerak bo'lsa, u qisqaroq bo'lishi mumkin. Agar ba'zi favqulodda vaziyatlar mavjud bo'lsa, transport xarajatlarini to'lasangiz, biz yuklarni havo ekspressi orqali jo'natishimiz mumkin.

6) Siz savdo kompaniyasi yoki ishlab chiqaruvchisiz?

Biz professional ishlab chiqaruvchilarmiz. Biz nafaqat asboblar fabrikamizga egamiz, balki sementlangan karbid zavodiga ham egamiz.

7) Sizning zavodingiz qayerda joylashgan?

Biz Xitoyning Xunan provinsiyasining Chjuchjou shahrida, volfram karbid bazasida joylashganmiz.

8) Namuna olishni qancha vaqt kutishim mumkin?

Namuna to'lovini to'laganingizdan va bizga tasdiqlangan fayllarni yuborganingizdan so'ng, namunalar 3-7 kun ichida yetkazib berishga tayyor bo'ladi. Namunalar sizga ekspress orqali yuboriladi va 3-5 ish kunida keladi. Siz o'zingizning ekspress hisobingizdan foydalanishingiz yoki hisobingiz bo'lmasa, bizga oldindan to'lashingiz mumkin.

9) Sizning aktsiyalaringiz haqida nima deyish mumkin?

Bizda ko'p miqdordagi mahsulotlar mavjud, oddiy turlar va o'lchamlar hammasi stokda.

10) Bepul etkazib berish mumkinmi?

Biz bepul yetkazib berish xizmatini taklif qilmaymiz. Agar siz ko'p miqdorda mahsulot sotib olsangiz, chegirmaga ega bo'lishimiz mumkin

Men bilan bog'laning:

Aimee

Sotish bo'yicha menejer

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tyanyuan tuman, Chjuchjou shahari.

Elektron pochta: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688