- Materials: 100% raw material tungsten carbide

- HRC:55

- Flute:2/4

- Suitable for:Stainless steel/45# steel/tool steel/abrasive steel/carbon steel, etc.

Isapejuwe

Product Detail:

This HRC55 2-flute carbide ball nose end mill represents the pinnacle of hard milling technology. It is expertly engineered to deliver exceptional surface finish and extended tool life when machining the toughest materials.

Uncompromising Performance on Hardened Steel: Designed specifically for materials with a hardness up to HRC55, this tool maintains its edge integrity and geometry in demanding applications. Its robust structure ensures minimal deflection and chatter, allowing you to achieve the highest standards of precision and surface quality on mold steels and hardened alloys.

Precision Ball Nose Geometry: The advanced ball nose design is optimized for 3D contouring and complex curved surface machining. It minimizes step-over marks and guarantees a consistently smooth and accurate profile, crucial for final part quality in the mold and die industry.

Built-in Efficiency: The 2-flute structure is specifically tailored for hard milling, providing maximum core rigidity and efficient heat dissipation. This design ensures superior chip evacuation and prevents thermal stress, allowing for higher cutting speeds and feed rates.

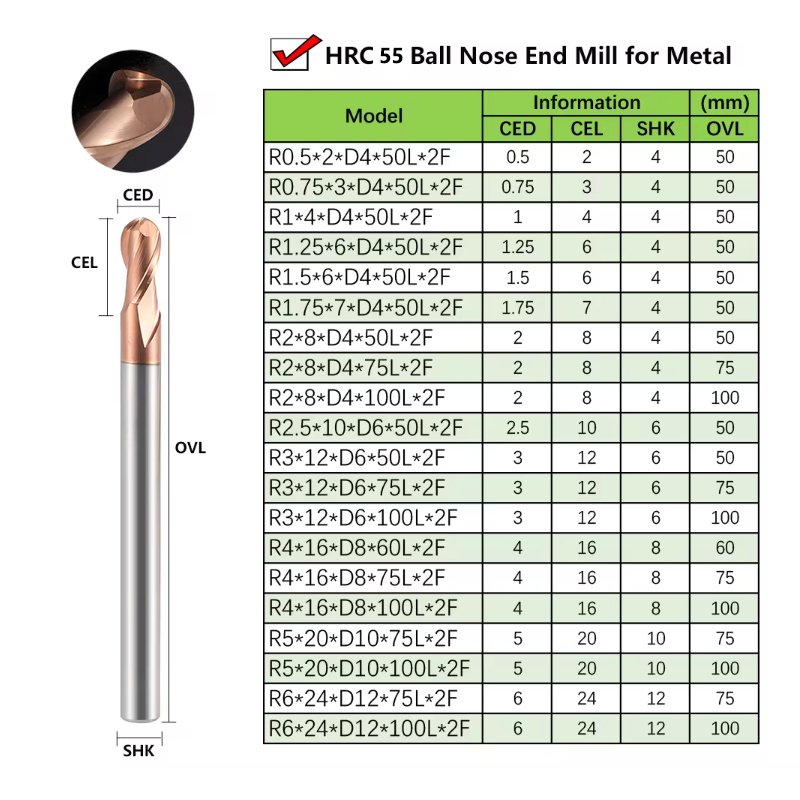

Product Specifications

These specifications detail the exact configuration of the D8x75mm HRC55 ball nose end mill.

Tool Type: Ball Nose End Mill / Radius End Mill

Number of Flutes: 2 Flutes

Maximum Hardness: HRC ≤ 55°

Shank Diameter (D1): 8mm (Nominal)

Cutting Diameter (D2): 8mm (Nominal)

Overall Length (L): 75mm (Medium-Long Reach)

Tool Material: Premium Micro-Grain Solid Carbide

Coating: High-Performance, High-Temperature Coating (e.g., AlTiN or similar)

Applicable Materials: Hardened Steel, Mold Steel, High-Hardness Alloys (e.g., 718, S136, NAK80 after heat treatment)

Primary Applications: Precision Finishing, Semi-Finishing, 3D Contouring, Medium-Depth Pocket Milling.

Large quantity with big discount.

FAQ

1) Nigbawo ni MO le gba idiyele naa?

A maa n sọ laarin awọn wakati 24 lẹhin ti a gba ibeere rẹ.Ti o ba ni iyara pupọ lati gba idiyele naa, jọwọ pe wa tabi sọ fun wa ninu imeeli rẹ ki a le ṣe akiyesi pataki ibeere rẹ.

2) Bawo ni MO ṣe le gba ayẹwo lati ṣayẹwo didara rẹ?

Lẹhin ijẹrisi idiyele, o le nilo fun awọn ayẹwo lati ṣayẹwo didara wa. Ti o ba kan nilo ayẹwo òfo lati ṣayẹwo apẹrẹ ati didara iwe, a yoo fun ọ ni ayẹwo fun ọfẹ, niwọn igba ti o ba ni ẹru ọkọ oju-omi kiakia.

3) Igba melo ni MO le reti lati gba ayẹwo naa?

Lẹhin ti o san idiyele ayẹwo ati firanṣẹ awọn faili ti a fọwọsi, awọn ayẹwo yoo ṣetan fun ifijiṣẹ ni awọn ọjọ 3-7. Awọn ayẹwo naa yoo ranṣẹ si ọ nipasẹ kiakia ati de ni awọn ọjọ iṣẹ 3-7. O le lo akọọlẹ kiakia ti ara rẹ tabi sanwo tẹlẹ wa ti o ko ba ni akọọlẹ kan.

4) Bawo ni pipẹ gbogbo ilana ti n ṣiṣẹ jade?

Lẹhin ti o paṣẹ, akoko mimu iṣelọpọ jẹ nipa awọn ọjọ 20-25. A nilo awọn ọjọ 7 lati ṣeto gbogbo nkan naa lẹhinna awọn ọjọ 15 fun iṣelọpọ.

5) Kini nipa gbigbe ati ọjọ ifijiṣẹ?

Ni deede a lo gbigbe lati gbe awọn ọja naa pada. O jẹ nipa awọn ọjọ 7-25. O tun da lori iru ile-iṣẹ ati ibudo ti o wa. O le jẹ kukuru ti o ba nilo lati firanṣẹ awọn ọja bi Asia. Ti o ba wa diẹ ninu awọn pajawiri a le fi awọn ẹru ranṣẹ nipasẹ afẹfẹ kiakia, niwọn igba ti o ba ni owo-owo ijabọ naa.

6) Ṣe o jẹ ile-iṣẹ iṣowo tabi olupilẹṣẹ?

A ni o wa ọjọgbọn olupese. A ko ni ile-iṣẹ irinṣẹ wa nikan, ṣugbọn tun ni ile-iṣẹ carbide ti simenti.

7) Nibo ni ile-iṣẹ rẹ wa?

A wa ni ilu Zhuzhou, Hunan Province., Tungsten carbide base town of China

8) Igba melo ni MO le reti lati gba ayẹwo naa?

Lẹhin ti o san idiyele ayẹwo ati firanṣẹ awọn faili ti a fọwọsi, awọn ayẹwo yoo ṣetan fun ifijiṣẹ ni awọn ọjọ 3-7. Awọn ayẹwo naa yoo ranṣẹ si ọ nipasẹ kiakia ati de ni awọn ọjọ iṣẹ 3-5. O le lo akọọlẹ kiakia ti ara rẹ tabi sanwo tẹlẹ wa ti o ko ba ni akọọlẹ kan.

9) Bawo ni nipa ọja iṣura rẹ?

A ni awọn ọja ti o tobi pupọ ni iṣura, awọn oriṣi deede ati awọn titobi gbogbo wa ni iṣura.

10) Ṣe ifijiṣẹ ọfẹ ṣee ṣe?

A ko funni ni iṣẹ gbigbe ọfẹ. A le ni ẹdinwo ti o ba ra ọja ti o tobi pupọ

Lero lati kan si mi:

Aimee

Alabojuto nkan tita

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Agbegbe, Zhuzhou Ilu.

Imeeli: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688