Ungakukhetha kanjani ukuguquguquka kufakwa ngokwesayensi?

Ukukhethwa kokuguqulwa kokuguqulwa kuthinta ngqo ukusebenza kwemishini, impilo yamathuluzi kanye nekhwalithi yokusebenza. Lokhu okulandelayo kuhlaziya isinqumo esibalulekile sesinqumo kusuka kubukhulu obuhlanu: Izakhiwo ezibonakalayo, amapharamitha wejometri, ubuchwepheshe be-coating, izimo zemishini kanye nomnotho.

Izinto ezibonakalayo: "Hardeness" ehambelana nezinto zokucubungula

Ukuhlukaniswa kwamamaki we-carbide anenkohliso

Uhlobo lwe-YG (olususelwa ku-Cobalt): Ilungele izinsimbi zensimbi nezinsimbi ezingezona ezonakele, njenge-YG6x (imishini evuthayo), i-YG3X (Ukuqeda Imishini)

Uhlobo lwe-yt (i-titanium-based): isetshenziselwa ukusika kwensimbi, njenge-yt15 (inhloso ejwayelekile), i-yt30 (ukuqeda imininingwane)

Uhlobo lwe-yw (i-allwoy ye-Universal): Ukukhetha kokuqala kwensimbi engenasici kanye nokuvimbela ukushisa, njenge-yw1 (inhloso ejwayelekile), yw2 (ukugqokwa okuvinjezelwa)

Ama-blades we-ceramic: alungele izinto zokwakha kanzima (HRC45 nangaphezulu), kepha ngenhla), kepha zingenagazi futhi zidinga okuphakelayo okuphansi

I-CBN BLADES: Ukukhetha okuphezulu kwemishini esezingeni eliphezulu yensimbi elukhuni (HRC55 +) ne-cast iron

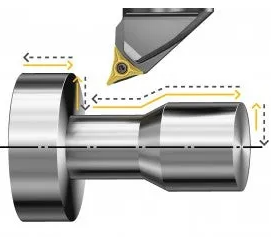

Amapharamitha we-geometric: "Ikhodi engabonakali" enquma ukunciphisa ukusebenza

I-1.TIP Radius (r)

I-Rough Machching: 0.8-1.2mm (Khulisa amandla)

Imashini amahle: 0.4-0.8mm (Yehlisa ubulukhuni bendawo)

Ukusikwa okwenziwe ngezikhathi ezithile kudinga i-radius encane ukunciphisa umthelela

2.Rake Angle (γ0)

I-Angle Emihle Beka (8 ° -15 °): Amandla wokusika aphansi, alungele ama-aluminium alloys kanye nensimbi engagqwali

I-HIGHCA CANELLE (-5 ° -0 °): Ubulukhuni obuphezulu, obusetshenziselwa insimbi nensimbi

I-3.Back Angle (α0)

Imishini evuthayo: 6 ° -8 ° (Yehlisa Ithuluzi Lasemuva)

Imashini amahle: 10 °-12 ° (Yehlisa ukuxabana)

Ukwelashwa kwe-4.

Unqenqema lokuhlonipha (0.02-0.05mm): Ukucutshungulwa okujwayelekile

Unqenqemeni oluhlanganisiwe (0.05-0.2mm × -15 °): Ukusika okungaphakathi kanye nokuhlanza

Ubuchwepheshe be-coating: "Izembatho Zomlingo" ekhulisa impilo yonke

1.General coating

I-Tialn (igolide): Ukumelana ne-oxidation ephezulu yokushisa i-oxidation (1100 ° C), ilungele izingxenye zensimbi

I-TiCn (Grey): Ubulukhuni obuphezulu, olufanele i-Iron Iron

I-Alcrn (Blue-Grey): Anti-Adhesion ngokucubungula insimbi engenasici

2.Special coatial

I-Diamond Coating: Ukucutshungulwa kwe-Ultra-Fine kwe-Aluminium Alloy ne-Graphite

Ukuhlanganiswa okuhlanganisiwe (okufana ne-tialn + mos2 mos2): anti-ukungqubuzana kwensimbi ejulile yensimbi ejulile

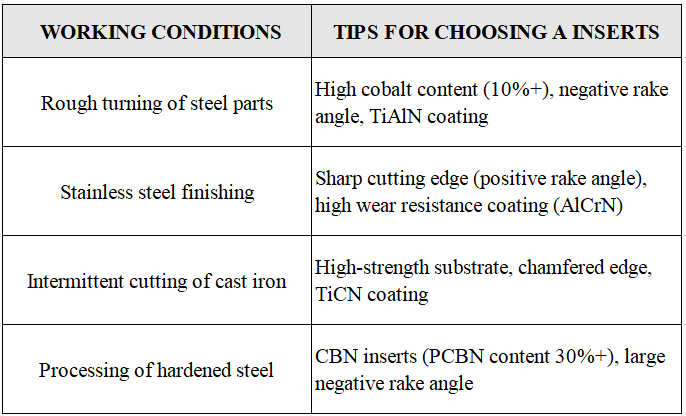

Ukucubungula isimo se-Scenario: Isixazululo esifanele ngaphansi kwezimo ezahlukahlukene zokusebenza

Amakhono Asebenzayo: Ukuxilongwa okusheshayo kwe-blade ukwehluleka

Flank Wear (VB> 0.3mm): Ukwehluleka kwe-coating noma okuphakelayo ngokweqile

0.3mm): Ukwehluleka kwe-coating noma okuphakelayo ngokweqile

Umphetho ophukile: amandla anganele, kudingeka ukhuphule i-chamfer noma ukunciphisa ukujula kokusika

Unqenqema owakhelwelwe