- Materials: 100% raw material tungsten carbide

- HRC:55

- Flute:2/4

- Suitable for:Stainless steel/45# steel/tool steel/abrasive steel/carbon steel, etc.

Ukufanisa

Product Detail:

This HRC55 2-flute carbide ball nose end mill represents the pinnacle of hard milling technology. It is expertly engineered to deliver exceptional surface finish and extended tool life when machining the toughest materials.

Uncompromising Performance on Hardened Steel: Designed specifically for materials with a hardness up to HRC55, this tool maintains its edge integrity and geometry in demanding applications. Its robust structure ensures minimal deflection and chatter, allowing you to achieve the highest standards of precision and surface quality on mold steels and hardened alloys.

Precision Ball Nose Geometry: The advanced ball nose design is optimized for 3D contouring and complex curved surface machining. It minimizes step-over marks and guarantees a consistently smooth and accurate profile, crucial for final part quality in the mold and die industry.

Built-in Efficiency: The 2-flute structure is specifically tailored for hard milling, providing maximum core rigidity and efficient heat dissipation. This design ensures superior chip evacuation and prevents thermal stress, allowing for higher cutting speeds and feed rates.

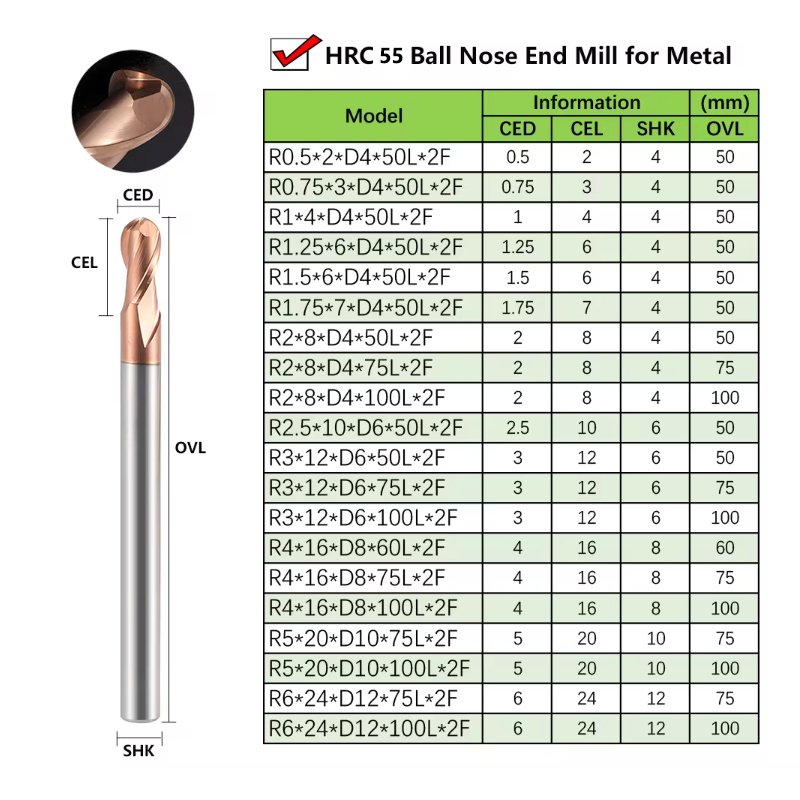

Product Specifications

These specifications detail the exact configuration of the D8x75mm HRC55 ball nose end mill.

Tool Type: Ball Nose End Mill / Radius End Mill

Number of Flutes: 2 Flutes

Maximum Hardness: HRC ≤ 55°

Shank Diameter (D1): 8mm (Nominal)

Cutting Diameter (D2): 8mm (Nominal)

Overall Length (L): 75mm (Medium-Long Reach)

Tool Material: Premium Micro-Grain Solid Carbide

Coating: High-Performance, High-Temperature Coating (e.g., AlTiN or similar)

Applicable Materials: Hardened Steel, Mold Steel, High-Hardness Alloys (e.g., 718, S136, NAK80 after heat treatment)

Primary Applications: Precision Finishing, Semi-Finishing, 3D Contouring, Medium-Depth Pocket Milling.

Large quantity with big discount.

FAQ

1) Ngingayithola nini intengo?

Sivame ukucaphuna kungakapheli amahora angu-24 ngemva kokuthola umbuzo wakho.Uma uphuthuma kakhulu ukuthola inani, sicela usishayele noma usitshele ku-imeyili yakho ukuze sizobheka umbuzo wakho oza kuqala.

2) Ngingayithola kanjani isampula ukuhlola izinga lakho?

Ngemuva kokuqinisekiswa kwentengo, ungadinga amasampula ukuze uhlole ikhwalithi yethu. Uma nje udinga isampula elingenalutho ukuze uhlole ukwakheka kanye nekhwalithi yephepha, sizokunikeza isampula mahhala, inqobo nje uma ukwazi ukukhokhela impahla esheshayo.

3) Ngingalindela isikhathi esingakanani ukuthola isampula?

Ngemva kokukhokha inkokhiso yesampula futhi usithumelele amafayela aqinisekisiwe, amasampula azobe elungele ukulethwa ezinsukwini ezingu-3-7. Amasampula azothunyelwa kuwe nge-express futhi afike ezinsukwini zokusebenza ezi-3-7. Ungasebenzisa i-akhawunti yakho ye-express noma usikhokhele kusengaphambili uma ungenayo i-akhawunti.

4) Ngabe yonke inqubo yenziwa isikhathi esingakanani?

Ngemva kokufaka i-oda, isikhathi sokuphatha ukukhiqiza singaba yizinsuku ezingama-20-25. Sidinga izinsuku eziyi-7 ukulungisa zonke izinto bese kuba yizinsuku eziyi-15 zokukhiqiza.

5) Kuthiwani ngosuku lokuhamba nokulethwa?

Imvamisa sisebenzisa ukuthunyelwa ukudlulisa impahla.Kungaba yizinsuku eziyi-7-25.Futhi kuya ngokuthi ukuyiphi i-coutry nechweba.Kungaba kufushane uma udinga ukuthumela impahla efana ne-Asian. Uma kunezimo eziphuthumayo singathumela izimpahla nge-air Express, inqobo nje uma ukwazi ukukhokhela izindleko zomgwaqo.

6) Ingabe uyinkampani yokuhweba noma umenzi?

Singumkhiqizi ochwepheshe. Asigcini nje ngokuba ngabanikazi bemboni yethu yamathuluzi, kodwa futhi sinefektri ye-carbide enosimende.

7) Ikuphi imboni yakho?

Sitholakala edolobhaneni lase-Zhuzhou, esifundazweni sase-Hunan., i-tungsten carbide base town yase-China.

8) Ngingalindela isikhathi esingakanani ukuthola isampula?

Ngemva kokukhokha inkokhiso yesampula futhi usithumelele amafayela aqinisekisiwe, amasampula azobe elungele ukulethwa ezinsukwini ezingu-3-7. Amasampula azothunyelwa kuwe nge-express futhi afike ezinsukwini zokusebenza ezi-3-5. Ungasebenzisa i-akhawunti yakho ye-express noma usikhokhele kusengaphambili uma ungenayo i-akhawunti.

9) Kuthiwani ngesitoko sakho?

Sinemikhiqizo eningi esitokweni, izinhlobo ezivamile namasayizi konke kusesitokweni.

10) Ingabe ukuthunyelwa kwamahhala kungenzeka?

Asinikezi isevisi yamahhala yokuthumela. Singaba nesaphulelo uma uthenga imikhiqizo eningi

Zizwe ukhululekile ukuxhumana nami:

Aimee

Umphathi wezentengiso

Inkampani Zhuzhou Chuangde Cemented Carbide Co

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

I-imeyili: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688