CBN Inserts vs. Carbide Inserts: The Cost-Effectiveness Formula for Hard Material Machining

CBN Inserts vs. Carbide Inserts: The Cost-Effectiveness Formula for Hard Material Machining

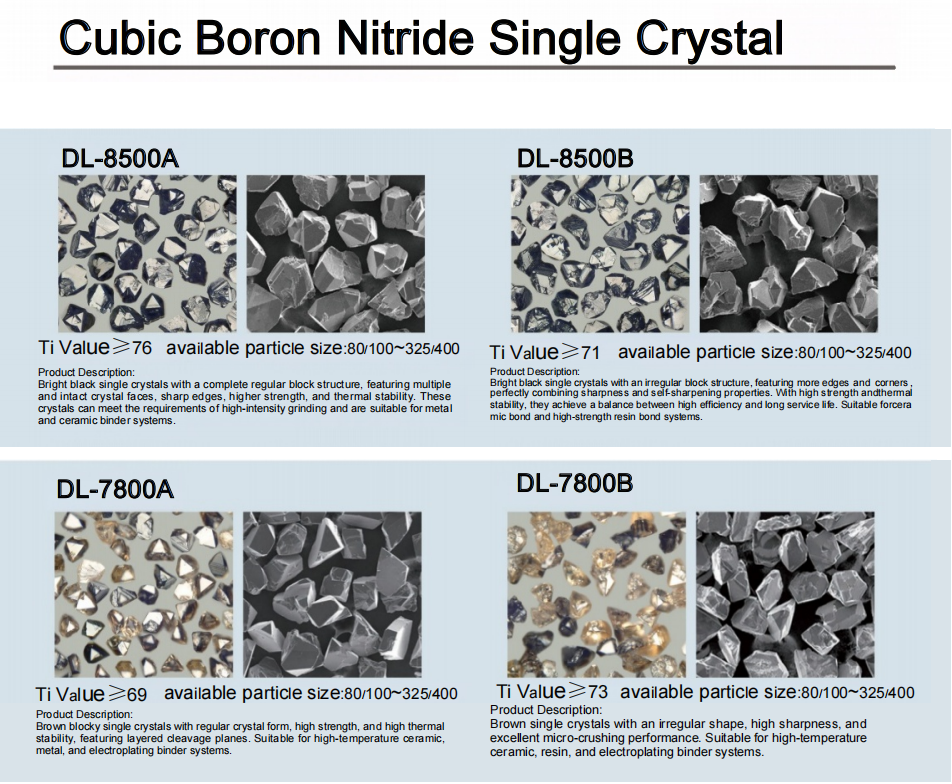

In modern manufacturing, hard material machining is becoming increasingly common, especially in industries such as automotive, aerospace, and tooling, where the hardness of workpieces often exceeds HRC50. In such cases, tool selection directly impacts productivity, machining quality, and overall costs. Among the available options, CBN (Cubic Boron Nitride) inserts and carbide inserts are two major solutions.

This article compares the two across four key dimensions—hardness, heat resistance, tool life, and cost—to clarify the optimal application boundaries of CBN inserts. It also presents a cost-benefit case study in automotive component machining.

I. Performance Comparison

1. Hardness

CBN Inserts: Second only to diamond in hardness, ideal for machining hardened steels above HRC50, powder metallurgy, and high-temperature alloys.

Carbide Inserts: Hardness around HRA90. Tool wear accelerates significantly when machining materials above HRC45.

2. Heat Resistance

CBN Inserts: Withstand temperatures up to 1200°C, suitable for high-speed dry cutting, reducing coolant usage.

Carbide Inserts: Heat resistance up to ~800°C; prone to plastic deformation and flank wear at high speeds.

3. Tool Life

CBN Inserts: Can last 5–10 times longer than carbide when machining hardened materials, offering greater stability.

Carbide Inserts: Tool life drops sharply on hard materials, requiring frequent replacement and causing downtime.

4. Cost

CBN Inserts: Higher upfront cost per insert, but cost per part decreases due to longer life.

Carbide Inserts: Lower initial cost, but frequent replacement raises overall cost.

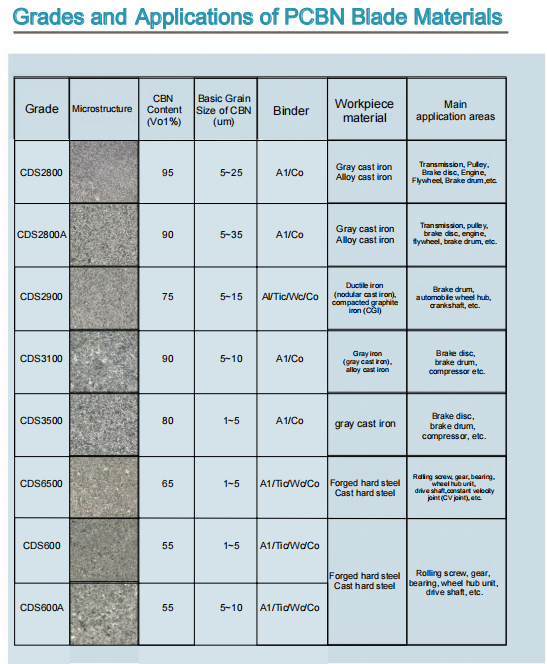

II. Application Boundaries of CBN Inserts

Based on these indicators, the optimal scenarios for CBN inserts can be summarized as:

Material hardness: HRC50 and above, such as hardened steels, powder metallurgy, and high-temperature alloys.

Production batch size: Medium to large volumes, where tool life advantage offsets cost.

Precision requirements: Dimensional tolerance IT6 or better, surface roughness Ra ≤ 0.8 μm.

Machining method: High-speed dry cutting, semi-finishing, or finishing.

When material hardness is lower (below HRC45), batch size is small, or precision requirements are moderate, carbide inserts remain the more cost-effective choice.

III. Automotive Component Case Study

Taking post-heat-treatment finishing of automotive transmission gears as an example:

Material: 20CrMnTi, hardened to HRC58–62.

Machining requirements: Dimensional accuracy IT6, surface roughness Ra0.8.

| Item | CBN Insert | Carbide Insert |

|---|---|---|

| Insert price | ~5× higher than carbide | Baseline |

| Tool life | 6× longer | 1× (baseline) |

| Downtime for tool change | Low | High |

| Machining efficiency | High-speed dry cutting, +20% efficiency | Low-speed cutting, coolant required |

| Cost per part | ~15% lower | Baseline |

Result: In high-hardness, large-batch, high-precision gear machining, although CBN inserts are more expensive per piece, their longer life, fewer tool changes, and higher efficiency reduce per-part costs while ensuring consistent quality and lower scrap rates.

IV. Conclusion and Tool Selection Formula

For workpieces above HRC50, with high precision and large-batch requirements, CBN inserts deliver the best cost-performance ratio, significantly reducing overall manufacturing costs and boosting efficiency. For lower hardness or small-batch jobs, carbide inserts remain practical and economical.

Simplified Tool Selection Formula:

If (Material Hardness ≥ HRC50) AND (Batch Size ≥ Medium) AND (Precision ≥ IT6) → Choose CBN Insert

Else → Choose Carbide Insert

Enterprises can use this formula as a quick decision reference, while also considering equipment capacity, cutting speed, and cooling conditions. Establishing a complete cost-benefit analysis model for tool selection will maximize production efficiency and competitiveness.