- Burrs are made of tungsten carbide steel, which prevent bending, reduce vibration and extend service life

- Rotary burrs can be widely used in processing all kinds of metal and non-metal, such as alloy steel, stainless steel, wood and marble.

- Suitable for cast iron, cast steel, carbon steel, wood, plastic, glass, stone, alloy steel, stainless steel, marble, jade, etc.

Faʻamatalaga

Product Overview

The Carbide Burr (also known as a rotary file) is a high-performance, durable cutting tool designed for deburring, chamfering, grooving, engraving, and finishing metals, wood, plastics, and composite materials. Made from ultra-fine grain tungsten carbide, it offers exceptional hardness and wear resistance, making it ideal for high-speed rotary applications such as pneumatic tools, electric grinders, and CNC machines.

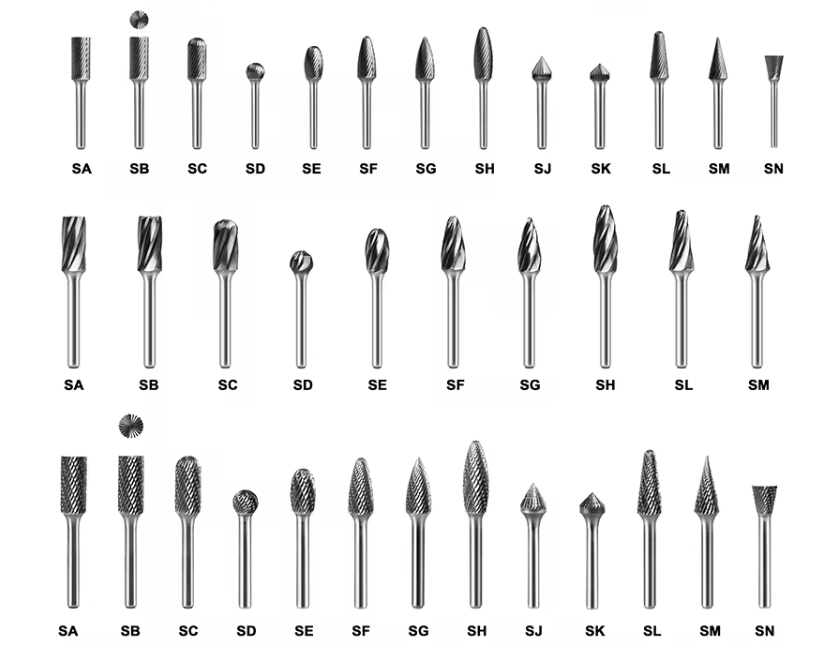

Common Models & Specifications

Shank Diameter: 3mm (1/8"), 6mm (1/4")

Cutting Length: 10mm–50mm (customizable)

Cut Type: Single-cut (aggressive), double-cut (general-purpose), spiral-cut (fine finish)

Coating: Uncoated (standard), TiAlN-coated (enhanced heat resistance)

Why Choose Our Carbide Burrs?

✔ Strict QC – Each burr undergoes hardness testing and dynamic balancing checks.

✔ Cost-Effective – 20%-30% more affordable than European/American brands with comparable durability.

✔ Fast Delivery – Samples available, bulk orders shipped worldwide.

Key Features

✅ High Hardness & Wear Resistance – Premium carbide material ensures longer lifespan than HSS (High-Speed Steel), suitable for heavy-duty machining.

✅ Multiple Cut Styles – Single-cut, double-cut, spiral-cut, and diamond-cut designs for different materials (aluminum, steel, cast iron, titanium, etc.).

✅ Precision Machining – Sharp cutting edges deliver smooth finishes, reducing the need for secondary processing.

✅ Wide Compatibility – Works with pneumatic die grinders, electric engravers, and CNC routers (1/4" or 6mm shank standard).

✅ Heat & Shock Resistant – Optimized for high-speed cutting (recommended RPM: 10,000–35,000).

FAQ

1) O afea e mafai ai ona ou maua le tau?

E masani ona matou sii maia i totonu ole 24 itula talu ona maua lau suʻesuʻega.Afai e te matua faanatinati e maua le tau, faʻamolemole valaʻau mai pe taʻu mai ia i matou i lau imeli ina ia matou manatu i lau suʻesuʻega faʻamuamua.

2) E mafai faapefea ona ou maua se faʻataʻitaʻiga e siaki ai lou tulaga lelei?

A maeʻa faʻamaoniga tau, e mafai ona e manaʻomia mo faʻataʻitaʻiga e siaki ai lo matou lelei. Afai e te manaʻomia se faʻataʻitaʻiga avanoa e siaki ai le mamanu ma le tulaga lelei o pepa, matou te tuʻuina atu ia te oe faʻataʻitaʻiga e aunoa ma se totogi, pe afai e te gafatia le uta faʻaalia.

3) O le a le umi e mafai ona ou faʻamoemoe e maua ai le faʻataʻitaʻiga?

A maeʻa ona e totogiina le tau faʻataʻitaʻiga ma auina mai ia i matou faila faʻamaonia, o le a saunia faʻataʻitaʻiga mo le tuʻuina atu i le 3-7 aso. O faʻataʻitaʻiga o le a tuʻuina atu ia te oe e ala ile faʻaalia ma taunuu ile 3-7 aso faigaluega. E mafai ona e fa'aogaina lau oe fa'amatalaga fa'amatalaga pe totogi muamua matou pe a leai sau teugatupe.

4) O le a le umi e fa'atino ai le fa'agasologa atoa?

A maeʻa ona e tuʻuina se faʻatonuga, o le taimi e faʻatautaia ai le gaosiga e tusa ma le 20-25 aso. Matou te manaʻomia 7 aso e saunia ai mea uma ona 15 aso mo le gaosiga.

5) Ae faapefea le felauaiga ma le tuʻuina atu o aso?

E masani lava matou te faʻaaogaina uta e faʻafeiloaʻi ai oloa. E tusa ma le 7-25 aso. E faʻalagolago foi i le coutry ma le taulaga e te iai. Afai e iai ni fa'alavelave fa'afuase'i e mafai ona matou lafo atu oloa e ala i le ea express, pe afai e te gafatia le tau o felauaiga.

6) O oe kamupani fefaʻatauaʻiga poʻo le faʻatau?

O matou o le gaosiga faʻapolofesa. E le gata ina matou umia a matou fale gaosi mea faigaluega, ae o loʻo iai foʻi fale gaosi carbide sima.

7) O fea o iai lau falegaosimea?

O loʻo matou i totonu o le taulaga o Zhuzhou, Hunan Province., Tungsten carbide base taulaga o Saina

8) O le a le umi e mafai ona ou faʻamoemoe e maua ai le faʻataʻitaʻiga?

A maeʻa ona e totogiina le tau faʻataʻitaʻiga ma auina mai ia i matou faila faʻamaonia, o le a saunia faʻataʻitaʻiga mo le tuʻuina atu i le 3-7 aso. O faʻataʻitaʻiga o le a tuʻuina atu ia te oe e ala ile faʻaalia ma taunuu ile 3-5 aso faigaluega. E mafai ona e fa'aogaina lau oe fa'amatalaga fa'amatalaga pe totogi muamua matou pe a leai sau teugatupe.

9) Faʻafefea lau faʻasoa?

E tele a matou oloa i totonu o faʻatau, ituaiga masani ma lapopoa o loʻo i totonu uma.

10) E mafai ona lafo fua?

Matou te le ofo fua le felauaiga. E mafai ona matou maua se fa'aitiitiga pe afai e te fa'atau se oloa tele

Lagona le saoloto e fa'afeso'ota'i a'u:

Aimee

Pule fa'atau

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Imeli: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688