- FOR SP300 Inserts

- hardness: HRC42-46

- Processing range: Inner hole/through hole/blind hole/end face/deep hole processing

- Features: high rigidity ,Vibration reduction

DESCRIPTION

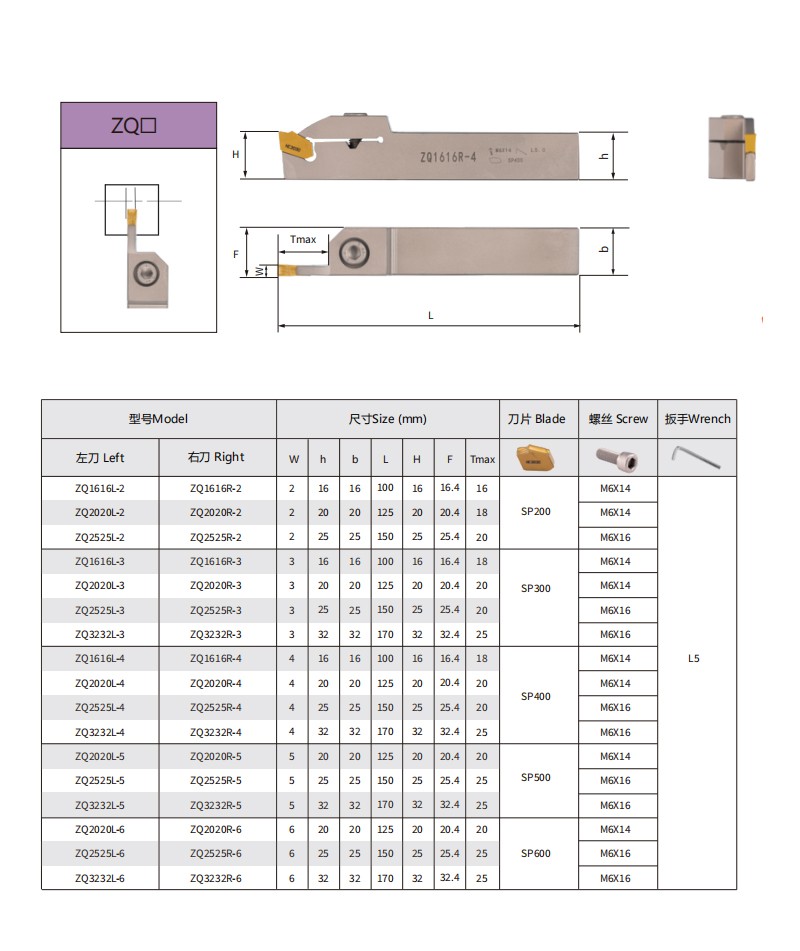

ZQ2020R-3 Parting & Grooving Tool Holder: Unmatched Reliability for High-Production Cut-Off

Built for durability and performance, the ZQ2020R-3 minimizes vibration and deflection, protecting your inserts and allowing for consistent, aggressive feeds and speeds. This translates to shorter cycle times, improved part quality, and significantly reduced cost per cut.

Key Features & Benefits:

Engineered for SP300 Inserts: Optimized geometry delivers superior chip control and breaking, preventing jamming and ensuring smooth, uninterrupted operations.

Ultra-Rigid 20x20mm Shank: Massive shank design absorbs cutting forces completely, eliminating deflection and chatter for clean, accurate cuts and extended tool life.

Secure Screw-Clamp System: Provides maximum insert security and reliability for aggressive cutting parameters and high-volume production.

Right-Hand Cut Direction (R): Standard configuration for optimal performance on most CNC lathes and turning centers.

Precision 3mm Cut Width (-3): Ideal for a wide range of general-purpose parting and grooving applications.

Boosts Productivity & Profitability: Reduces machine downtime, increases feed rates, and improves part consistency to lower your total cost of ownership.

Ideal for: High-volume manufacturing, automotive, and general machining shops that require a dependable, high-performance parting system for efficient cut-off and external grooving on CNC lathes.

FAQ

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2) How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you just need a blank sample to check the design and paper quality, we will provide you sample for free, as long as you afford the express freight.

3) How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-7 workdays. You can use your own express account or prepay us if you do not have an account.

4) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 20-25 days. We need 7 days to prepare all the stuff then 15 days for manufacturing.

5) What about the transportation and delivery date?

Normally we use shipment to transprot the goods.It is about 7-25 days.It also denpends on which coutry and port you are.It could be shorter if you need to send the goods like Asian. If there are some emergencies we can send the goods via air express, as long as you afford the traffic expense.

6) Are you trading company or manufaturer?

We are professional manufacturer. We not only owns our tools factory, but also have cemented carbide factory.

7) Where is your factory located?

We are located in Zhuzhou city , Hunan Province .,tungsten carbide base town of China

8) How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-5 workdays. You can use your own express account or prepay us if you do not have an account.

9) How about your stock?

We have large quantity products in stock, regular types and sizes are all in stock.

10) Is free shipping possible?

We don't offer free shipping service. We can have a discount if you buy a large quantity products