Introduction of carbide insert processing parameters and coatings

In modern manufacturing, carbide insert has become a core material in metal cutting, mining, mold manufacturing and other fields due to its excellent wear resistance, hardness and thermal stability.

一. Overview of carbide insert

Carbide insert is an alloy material made of micron-sized powder of high-hardness refractory metal carbides (WC, TiC, etc.) as the main component, with metals such as cobalt (Co), nickel (Ni) or molybdenum (Mo) as binders, and made by powder metallurgy. This unique composition structure gives carbide insert excellent properties such as hardness second only to diamond, red hardness up to 900-1000℃, and compressive strength up to 6000MPa, so that it can still maintain a stable working state under extreme working conditions.

二. Processing parameters of cemented carbide

(1) Cutting speed =VC

Cutting speed is a key parameter affecting the processing efficiency and tool life of carbide insert. Too high cutting speed will lead to increased friction between the tool and the workpiece, generate a lot of cutting heat, accelerate tool wear and even breakage; while too low cutting speed will reduce processing efficiency. Taking steel processing as an example, when using WC-Co carbide tools, the cutting speed is usually controlled at 80-150m/min; for titanium alloy materials, due to their poor thermal conductivity and high chemical activity, the cutting speed is generally controlled at 30-60m/min. In addition, the cutting speed needs to be appropriately adjusted according to the hardness of the workpiece material, the geometry of the tool and the performance of the processing equipment.

(2) Feed rate =FN

The feed rate determines the depth and width of the tool's penetration into the workpiece per unit time. A reasonable feed rate can ensure the stability of the cutting force and improve the surface processing quality. If the feed rate is too large, the cutting force will increase sharply, causing tool vibration, workpiece deformation, and even chipping; if the feed rate is too small, the processing time will be extended and the production cost will be increased. In actual processing, the feed rate can be appropriately increased during rough processing, generally at 0.2-0.5mm/r; during fine processing, in order to obtain a good surface finish, the feed rate is usually controlled at 0.05-0.2mm/r.

(3) Cutting depth =AP

The cutting depth directly affects the processing efficiency and processing accuracy. A larger cutting depth can reduce the number of processing times and improve production efficiency, but it will also increase the cutting force and cutting heat, and require higher rigidity of the tool and machine tool. Generally speaking, the cutting depth of carbide tools can be controlled at 0.5-3mm for rough processing, and 0.05-0.5mm for fine processing. For workpiece materials with higher hardness, the cutting depth should be appropriately reduced to avoid excessive wear of the tool.

3. Coating technology of cemented carbide

The role of coating

Coating technology is to coat one or more layers of thin films with special properties on the surface of cemented carbide tools to improve the wear resistance, oxidation resistance, adhesion resistance and cutting performance of the tools. The coating can effectively isolate the tool from the workpiece, reduce friction and wear during the cutting process, reduce cutting temperature, and extend the service life of the tool; at the same time, the coating can also improve the surface finish of the tool and improve the quality of the processed surface, especially in high-speed cutting and difficult-to-process materials. It has significant advantages.

CVD Coating

The surface of the cemented carbide substrate with cobalt-rich structure has uniform particle size and high bending strength. The special sintering process forms a gradient alloy structure, which is matched with a uniform and dense fine-grained coating and a unique post-processing technology to further improve toughness without reducing wear resistance. It is widely used in general processing of steel parts.

Most are black and yellow!

PVD Coating

The ultrafine cemented carbide substrate is matched with the Si-containing nano-coating, which has excellent wear resistance and oxidation resistance. It has excellent performance in the continuous processing of hard steel and stainless steel.

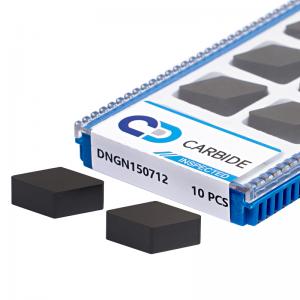

Most are black !